Electric power-based real-time monitoring method and system for oil well electric heating wax removal process

A technology of real-time monitoring and electric heating, applied in the field of soft measurement, can solve the problems of determining the cycle and duration of wax removal by electric heating, difficult to directly observe the problems of wax removal by electric heating, low production efficiency, etc., achieving low cost and effective Wax removal, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

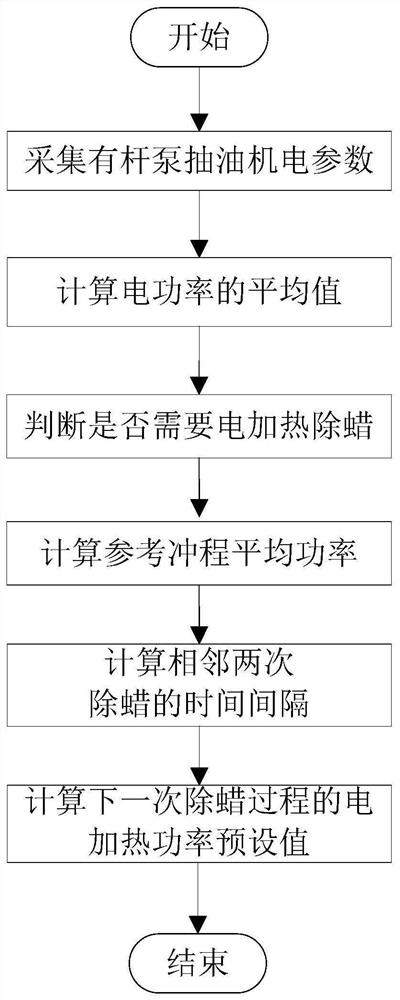

[0031] Such as figure 1 As shown, a real-time monitoring method for oil well electric heating wax removal process based on electric power, including:

[0032] Step 1: According to the preset electric heating power P, perform electric heating to remove wax from the oil well, and collect the electrical parameter data of the rod pump pumping unit in the working state during the electric heating wax removal process, and record the start of the electric heating wax removal process time is t 1 , the electrical parameters include three-phase voltage, three-phase current;

[0033] Step 2: According to the electrical parameter data of the rod pump pumping unit, calculate the average value of electric power of the rod pump pumping unit in one stroke cycle T, and the calculation formula is as follows:

[0034]

[0035] In the formula, m is the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com