Oil well paraffin removal method, device and equipment and storage medium

A technology for oil well and wax removal, which is applied to equipment and storage medium, oil well wax removal method and device field, can solve the problems of waste of investment cost, non-continuous heating, low utilization rate of medium frequency electric heating device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

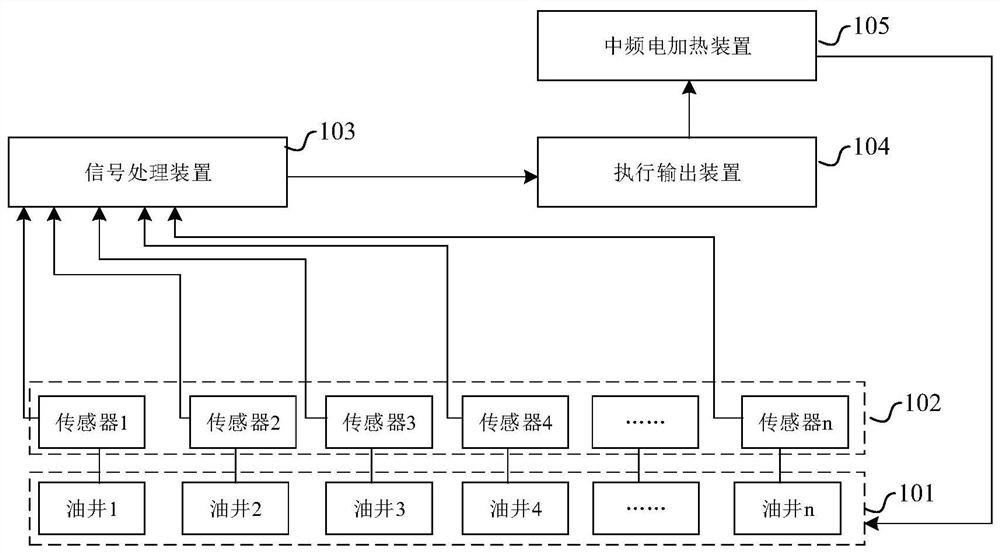

[0049] figure 1 It is a schematic diagram of an oil well wax removal system provided in the embodiment of this application. see figure 1 , the oil well wax removal system may include a plurality of oil wells 101 , a plurality of sensors 102 , a signal processing device 103 , an execution output device 104 and a medium frequency electric heating device 105 .

[0050] Such as figure 1 As shown, multiple oil wells 101 include oil well 1, oil well 2, oil well 3, oil well 4, ..., oil well n, and multiple sensors 102 include sensor 1, sensor 2, sensor 3, sensor 4 and sensor n, wherein n is positive integer. Wherein, each oil well is equipped with a sensor, such as oil well 1 is equipped with sensor 1, oil well 2 is equipped with se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com