Oil refining process pattern recognition and optimization method based on big data

An oil refining process and pattern recognition technology, applied in character and pattern recognition, design optimization/simulation, special data processing applications, etc., can solve the problem of real-time monitoring of changes in multiple modes of oil refining process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

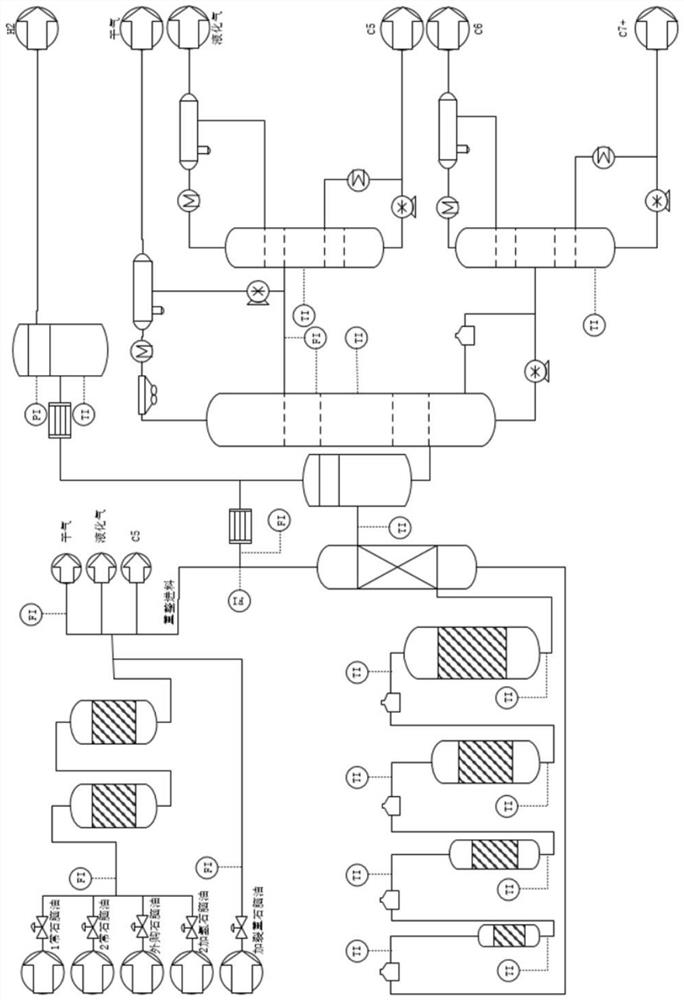

[0310] In this embodiment, the big data-based refinery process model optimization method of the present invention is applied to the catalytic reforming (CCR) process. figure 1 The flow chart of catalytic reforming process is given. The catalytic reforming process consists of a pre-hydrogenation unit, a reforming unit, and a catalyst regeneration system. For the purpose of producing aromatics, it also includes aromatics extraction and rectification units. The pretreated raw material enters the reforming section, is mixed with circulating hydrogen and heated, and then enters the reactor. There are 3 to 4 reactors connected in series, and a heating furnace is installed between them to compensate for the heat absorbed by the reaction. The material leaving the reactor enters the separator to separate the hydrogen cycle gas (the excess part is discharged), and the obtained liquid is used as reformed gasoline after removing light components from the stabilization tower, which is a hi...

Embodiment 2

[0377] In this embodiment, according to a certain 1.8 million tons / year industrial catalytic cracking production historical data, as shown in Table 4, select 88 device independent variable data points as model input variables and 20 device dependent variable data points as the output variables corresponding to the model , to collect and preprocess production history data.

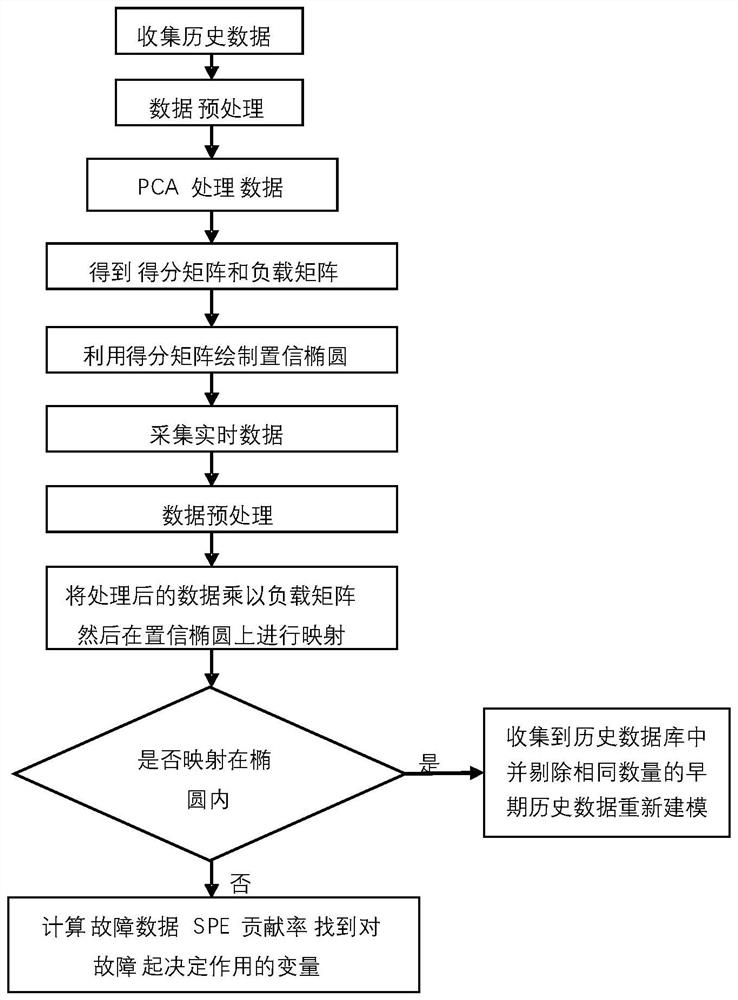

[0378] In this embodiment, a data-driven catalytic cracking unit operating state identification and optimization method of the present invention is used to identify and optimize the catalytic cracking unit operating state, such as Figure 10 shown, including the following steps:

[0379] 1. Collect the actual production history data of the device, see Table 4 for the names of related variables. The sample set Z=[z 1 ,z 2 ,...,z i ,...,z n ]∈R m×n , where z i =[z 1i ,z 2i ,...,z mi ] T represents the m samples of the ith measured variable.

[0380] Table 4: Catalytic unit model variable names

...

Embodiment 3

[0431] In this embodiment, according to a certain 600,000 tons / year industrial sulfur recovery production history data, as shown in Table 5, select 75 device data points, wherein 55 are model input variables, 20 are as output variables, and the production history data are processed acquisition and preprocessing.

[0432] In this embodiment, a method for identifying and optimizing the operating state of a sulfur recovery device based on data-driven methods of the present invention is used to identify and optimize the operating state of the sulfur recovery device, such as Figure 16 shown, including the following steps:

[0433] 1. Collect the actual production history data of the sulfur recovery unit, see Table 5 for the names of some independent variables. The sample set Z=[z 1 ,z 2 ,...,z i ,...,z n ]∈R m×n , where z i =[z 1i ,z 2i ,...,z mi ] T represents the m samples of the ith measured variable.

[0434] Table 5: Sulfur Plant Variable Names

[0435]

[043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com