High-ester leavening agent for preparing tea vinegar and prepared tea vinegar

A fermentation agent and high-ester technology, applied in the biological field, can solve the problems of product function and drinking taste that are not three-dimensional, multi-dimensional, ester flavor is not prominent, and the steps of tea vinegar are cumbersome, etc., to achieve unique mouth-killing power, unique aroma, and prevention The effect of Keshan disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

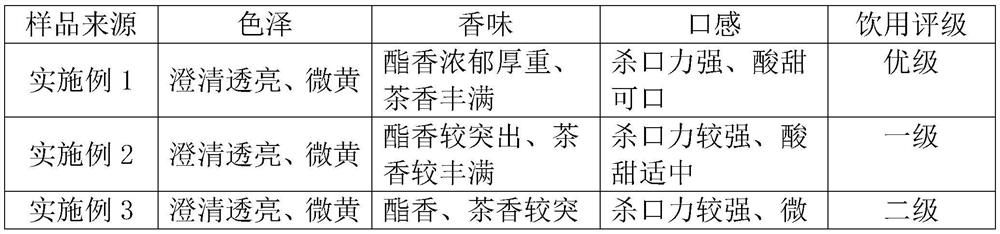

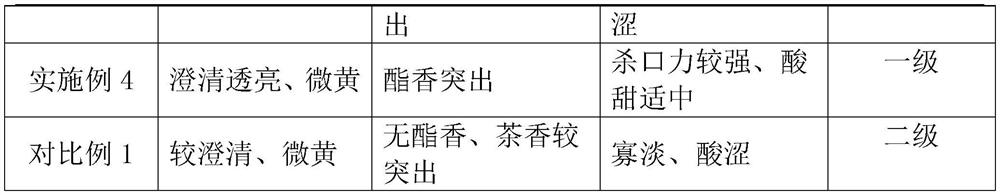

Examples

Embodiment 1

[0029] A high-ester starter for making tea vinegar. The raw materials and components used are: 30 parts of high-tolerance ester-producing yeast powder, 20 parts of acetic acid bacteria powder, 28 parts of sucrose, 21 parts of glucose, and 21 parts of corn gluten powder , 14 parts of maltodextrin, 7 parts of sodium selenite, and 7 parts of dipotassium hydrogen phosphate.

[0030] A preparation method for a high-ester starter for making tea vinegar, comprising the following steps:

[0031] (1) Strain activation: Take 5-10 copies of ester-producing yeast and acetic acid bacteria slant respectively, scrape a ring under a sterile environment, place them in ester-producing yeast seed medium and acetic acid bacteria seed medium respectively, and culture at 30°C to 10 9 Individual / ml, that is, the bacterial suspension;

[0032] (2) Preparation of primary seed liquid: Take 10-15 parts of the bacterial suspension and inoculate them into 1L of ester-producing yeast seed medium and acet...

Embodiment 2

[0042] A high-ester starter for making tea vinegar. The raw materials and components used are: 20 parts of high-tolerance ester-producing yeast powder, 10 parts of acetic acid bacteria powder, 28 parts of sucrose, 21 parts of glucose, and 21 parts of corn gluten powder , 14 parts of maltodextrin, 7 parts of sodium selenite, and 7 parts of dipotassium hydrogen phosphate.

[0043] A preparation method for a high-ester starter for making tea vinegar, comprising the following steps:

[0044] (1) Strain activation: Take 5-10 copies of ester-producing yeast and acetic acid bacteria slant respectively, scrape a ring under a sterile environment, place them in ester-producing yeast seed medium and acetic acid bacteria seed medium respectively, and culture at 30°C to 10 9 Individual / ml, that is, the bacterial suspension;

[0045] (2) Preparation of primary seed liquid: Take 10-15 parts of the bacterial suspension and inoculate them into 1L of ester-producing yeast seed medium and acet...

Embodiment 3

[0055] A high-ester starter for making tea vinegar. The raw materials and components used are: 30 parts of high-tolerance ester-producing yeast powder, 30 parts of acetic acid bacteria powder, 28 parts of sucrose, 21 parts of glucose, and 21 parts of corn gluten powder , 14 parts of maltodextrin, 7 parts of sodium selenite, and 7 parts of dipotassium hydrogen phosphate.

[0056] A preparation method for a high-ester starter for making tea vinegar, comprising the following steps:

[0057] (1) Strain activation: Take 5-10 copies of ester-producing yeast and acetic acid bacteria slant respectively, scrape a ring under a sterile environment, place them on the ester-producing yeast seed medium and the acetic acid bacteria seed medium respectively, and culture them statically at 30°C until 10 9 Individual / ml, that is, the bacterial suspension;

[0058] (2) Preparation of primary seed liquid: Take 10-15 parts of the bacterial suspension and inoculate them into 1L of ester-producing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com