High-density low-frictional-resistance drilling fluid

A low-friction, drilling fluid technology, applied in the field of oilfield drilling fluid, can solve the problems of difficult to meet drilling needs, high friction, high solid content, etc., to achieve low barite content, high inhibition performance, good rheological properties and filter loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

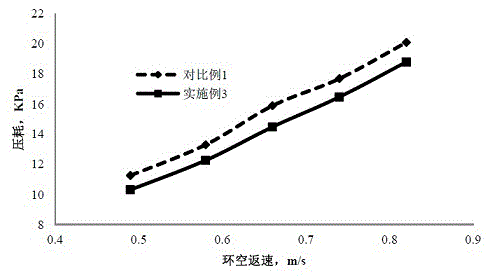

Image

Examples

preparation example B1

[0021] 26.0 grams of 2-methyl-2-acryloyloxypropylsulfonic acid, 39.0 grams of acrylamide, 20.0 grams of acrylic acid and 2.6 grams of 2-hydroxy-3-methacryloyloxypropyltrimethylammonium chloride were placed at room temperature Prepare an aqueous solution, adjust the pH value of the aqueous solution to 9.0 with sodium hydroxide, then add 0.05 grams of ammonium persulfate and 0.05 grams of sodium bisulfite to initiate polymerization, the initial temperature of the polymerization reaction is 20 ° C, and the polymerization time is 5 minutes. The product is granulated, dried and pulverized to obtain fluid loss reducer B1, whose structural formula is:

[0022]

preparation example B2

[0024] Mix 56.0 grams of 2-methyl-2-acryloyloxypropylsulfonic acid, 28.0 grams of acrylamide, 10.0 grams of acrylic acid and 2.8 grams of 2-hydroxy-3-methacryloyloxypropyltrimethylammonium chloride at room temperature Prepare an aqueous solution, adjust the pH value of the aqueous solution to 11.0 with sodium hydroxide, then add 0.2 grams of potassium persulfate and 0.2 grams of sodium thiosulfate to initiate polymerization, the initial temperature of the polymerization reaction is 50 ° C, and the polymerization time is 20 minutes. The product is granulated, dried and pulverized to obtain fluid loss reducer B2, whose structural formula is:

[0025]

[0026] Two, the embodiment

Embodiment 1

[0028] Take 270 grams of clear water, add 8.1 grams of sodium bentonite and 0.405 grams of sodium carbonate under high-speed stirring conditions, stir for 20 minutes, and seal and maintain at room temperature for 24 hours to obtain a base slurry. Take the above base slurry and add 1.35 grams of sodium hydroxide, 0.27 grams of xanthan gum, 10.675 grams of B10.675 grams, 2.7 grams of carboxymethyl cellulose sodium salt, 8.1 grams of sulfonated phenolic resin, 8.1 grams of sulfonated lignite, and 5.4 grams of polymer alcohol, (C1:C2=1:1) 270 grams, 167 grams of barite, stirred for 20 minutes, put into the aging tank at 135°C / 16 hours, and the density was 1.60g / cm 3 high-density low-friction drilling fluid.

[0029] Embodiment 2~4 steps are identical with embodiment 1, and clear water is 270 grams, and treatment agent kind and consumption are as shown in table 1.

[0030] Table 1 embodiment 2~4 treatment agent consumption

[0031]

[0032] Note: NaOH is sodium hydroxide, LV-C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com