Polyaspartic acid ester composition as well as preparation method and application thereof

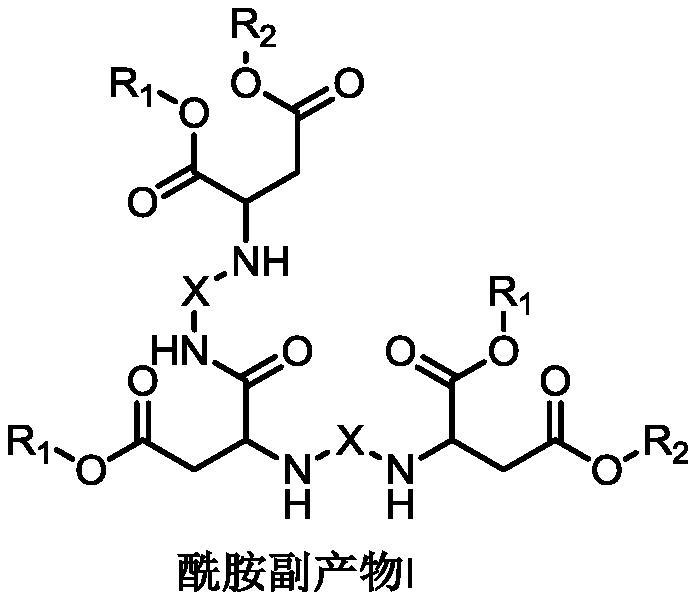

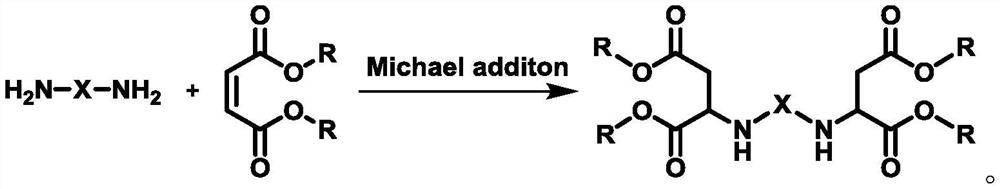

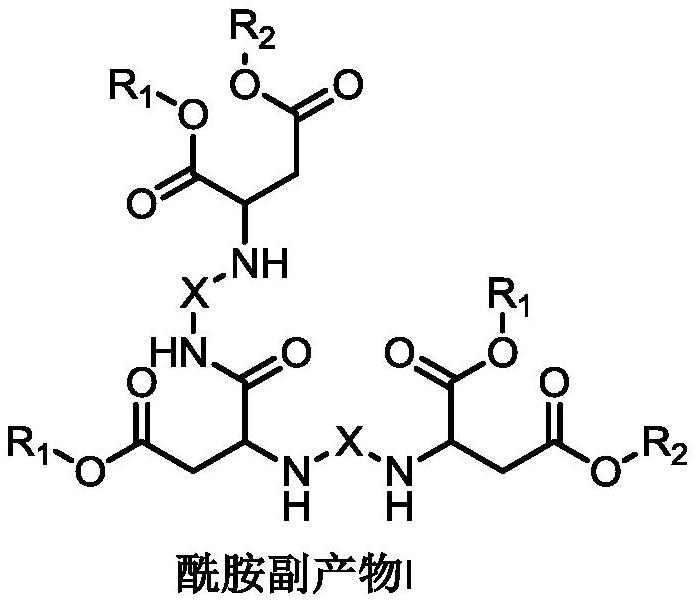

A polyaspartate, aspartate technology, applied in the direction of polyurea/polyurethane adhesives, polyurea/polyurethane coatings, adhesive types, etc., can solve the unclear effect of PAE performance, PAE The overall performance of the composition is reduced, and the content of by-products is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Step1: Add 1162g (10mol) of 2-methylpentamethylenediamine into a 20L glass reactor. The reactor is equipped with a mechanical stirring paddle, a thermometer, a constant pressure dropping funnel, and a N 2 Gas line pipe, bubbler, 3444g (20mol) diethyl butenedioate recycle liquid obtained by the separation of previous batches is added to the constant pressure dropping funnel, and N is introduced into the system. 2 After 10 minutes, the air in the system was replaced; under the condition of stirring at 30°C, diethyl butenedioate was slowly dropped into the flask for 0.5h at a constant speed, and the reaction temperature was controlled at 30°C for 2 hours. Then, 3444 g (20 mol) of diethyl maleate was added to the constant pressure dropping funnel, the temperature of the reaction system was lowered to 25° C., the supplementary liquid was added dropwise at a constant speed for 0.5 h, and the reaction was continued at 25° C. for 5 h. Stop the reaction, then add 23g (0.5%) ant...

Embodiment 2

[0103] Step1: Add 1051.8g (5mol) 4,4'-diaminodicyclohexylmethane into a 20L glass reactor. The reactor is equipped with a mechanical stirring paddle, a thermometer, a constant pressure dropping funnel, and a N 2 Gas line pipe, bubbler, 4304g (25mol) diethyl butenedioate obtained by the separation of the previous batch was added to the constant pressure dropping funnel, and N was passed into the system. 2 After 10 minutes, replace the air in the system; slowly drop diethyl maleate into the flask under the condition of stirring at 45°C, drop it at a constant speed for 1 hour, and control the reaction temperature to 45°C for 3 hours. Then, 1722 g (10 mol) of diethyl maleate was added to the constant pressure dropping funnel, the temperature of the reaction system was lowered to 30° C., the supplementary solution was added dropwise at a constant speed for 1 hour, and the reaction was continued at 30° C. for 6 hours. Stop the reaction, then add 2.77g (0.1%) antioxidant RIANOX MD-1...

Embodiment 3

[0110] Step1: Add 1192g (5mol) 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane into a 20L glass reactor, which is equipped with a mechanical stirring paddle, a thermometer, a constant pressure dropping funnel, Connected with N 2 Gas line pipe, bubbler, 5165g (30mol) diethyl butenedioate separated from the previous batch was added to the constant pressure dropping funnel, and N was introduced into the system. 2 After 10 minutes, replace the air in the system; slowly drop diethyl maleate into the flask under the condition of stirring at 50°C, drop it at a constant speed for 1 hour, and control the reaction temperature to 50°C for 4 hours. Then, 1722 g (10 mol) of diethyl maleate was added to the constant pressure dropping funnel, the temperature of the reaction system was lowered to 30° C., the supplementary liquid was added dropwise at a constant speed for 1 hour, and the reaction was continued at 30° C. for 8 hours. Stop the reaction, then add 2.91g (0.1%) antioxidant RIANOX M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com