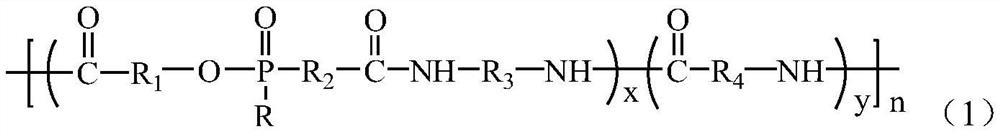

Organic phosphorus flame-retardant copolymer nylon and preparation method thereof

A technology of copolymerizing nylon and organophosphorus, which is applied in the fields of organophosphorus flame retardant copolymer nylon and its preparation, flame retardant copolymer nylon and its preparation, and achieves the effect of controllable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

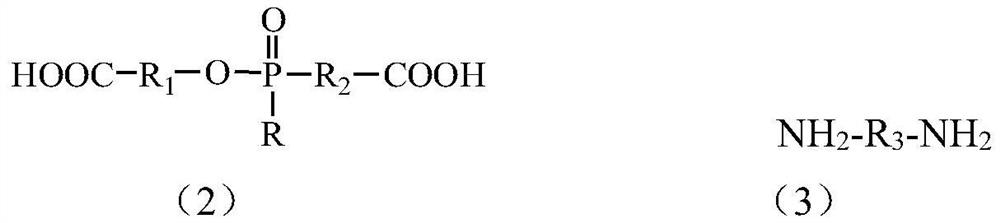

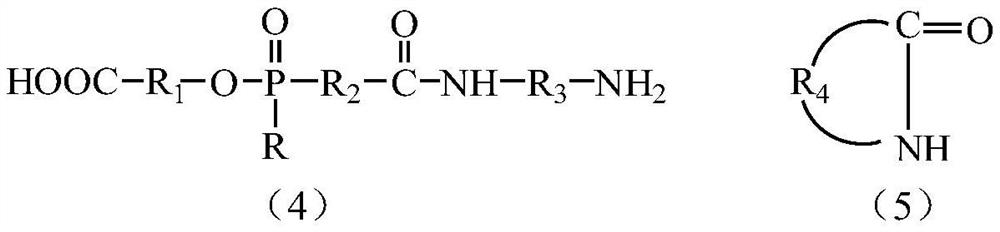

[0059] The preparation method of flame-retardant nylon of the present invention comprises the following steps:

[0060] (A) reacting organophosphorus flame retardant monomers or derivatives thereof with diamine monomers to make excess amino groups to prepare salts;

[0061] (B) allowing the reaction product of step (A) to react with a lactam to generate flame-retardant nylon.

[0062] In step (A), preferably, the flame retardant reacts with the diamine monomer in a molar ratio of 1:0.1-20, preferably 1:0.5-10, more preferably 1:1-2.

[0063] In step (A), the reaction can be carried out in a solvent such as water or an organic solvent such as an alcohol solvent. Preferably, a slight excess of diamine monomers is used so that the prepared salt solution has a pH of 7-9. The reaction temperature rose from room temperature to 40-70°C within 5-20 minutes.

[0064] Preferably, the diamine monomers described in step (A) are hexamethylenediamine, decanediamine, nonanediamine, undecan...

Embodiment 1

[0080] Stir and react the flame retardant monomer and hexamethylenediamine in a small amount of water at a molar ratio of 1:1.3 at 50°C for 0.5h, adjust the pH of the solution to 7.5, and dry to form a salt. Caprolactam monomer, above-mentioned salt (accounting for 6% of total monomer mass), each accounting for 1‰ of catalyst sodium hypophosphite, antioxidant p-phenylenediamine, molecular weight regulator benzoic acid, accounting for 3% of Ionized water was added to the reactor, vacuumed, filled with nitrogen three times, and finally the pressure inside the reactor was kept at 0.25MPa. Heat the reactor and keep stirring at a high speed. When the temperature of the reactor reaches 225° C. and the pressure is 1.75 MPa, keep the temperature and pressure constant for 2 hours. Then the temperature was raised to 260°C, and the pressure was released to normal pressure within 1.5 hours. Vacuumize to -0.05MPa. After the stirring speed drops to a certain value and stabilizes, fill nitr...

Embodiment 2

[0083] Stir and react the flame retardant monomer and hexamethylenediamine in a small amount of water at a molar ratio of 1:1.1 at 50°C for 40 minutes, adjust the pH of the solution to 7.3, and dry to form a salt. The decanolactam monomer, the above-mentioned salt (accounting for 7% of the total mass of the monomer), the catalyst toluenesulfonic acid each accounting for 1‰, and the antioxidant 2,6-di-tert-butyl-4-methylphenol , adipic acid as a molecular weight regulator, and 5% deionized water were added to the reactor, vacuumed, filled with nitrogen three times, and finally the pressure in the reactor was kept at 0.2 MPa. Heat the reactor and keep stirring at a high speed. When the temperature of the reactor reaches 220° C. and the pressure is 1.9 MPa, keep the temperature and pressure constant for 2 hours. Then the temperature was raised to 270°C, and the pressure was released to normal pressure within 2 hours. Vacuumize to -0.08MPa. After the stirring speed drops to a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com