Double-rotor pump-jet propeller and advancing tool adopting same

A dual-rotor pump and propeller technology, which is applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of limited installation space of the motor stator, complex structure of the external duct, and reduced propulsion efficiency of the propeller, etc. The effect of maintenance, saving production and maintenance costs, and improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

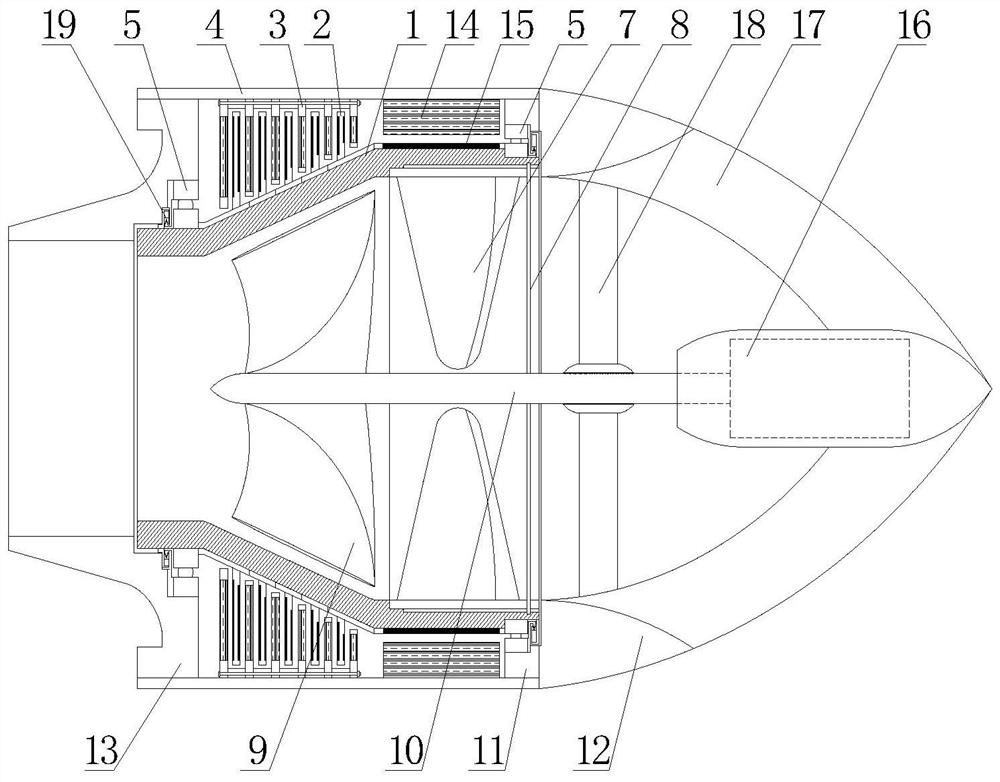

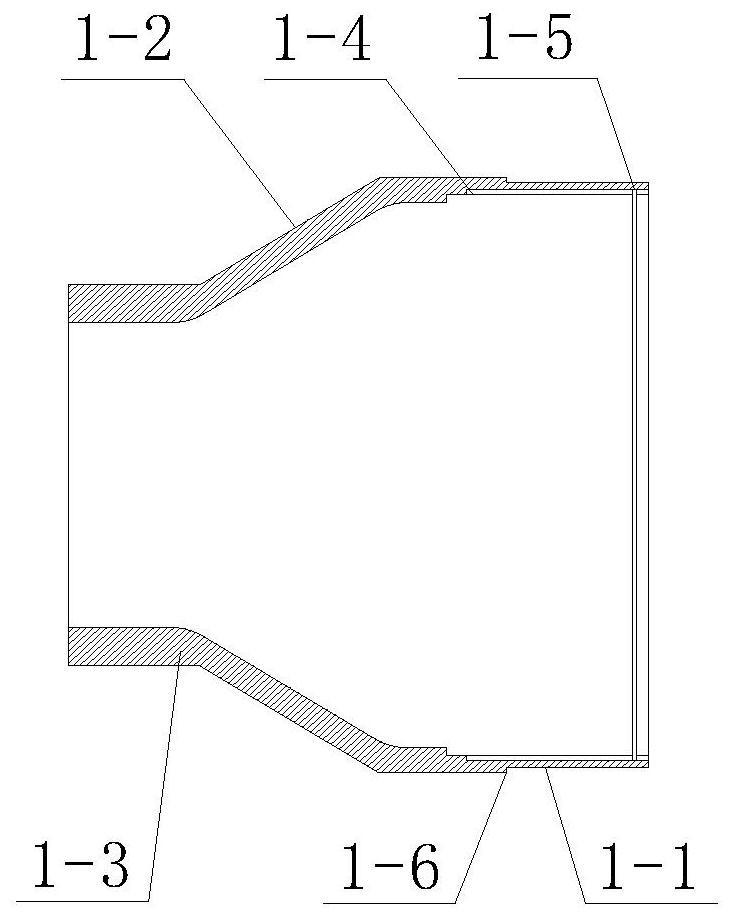

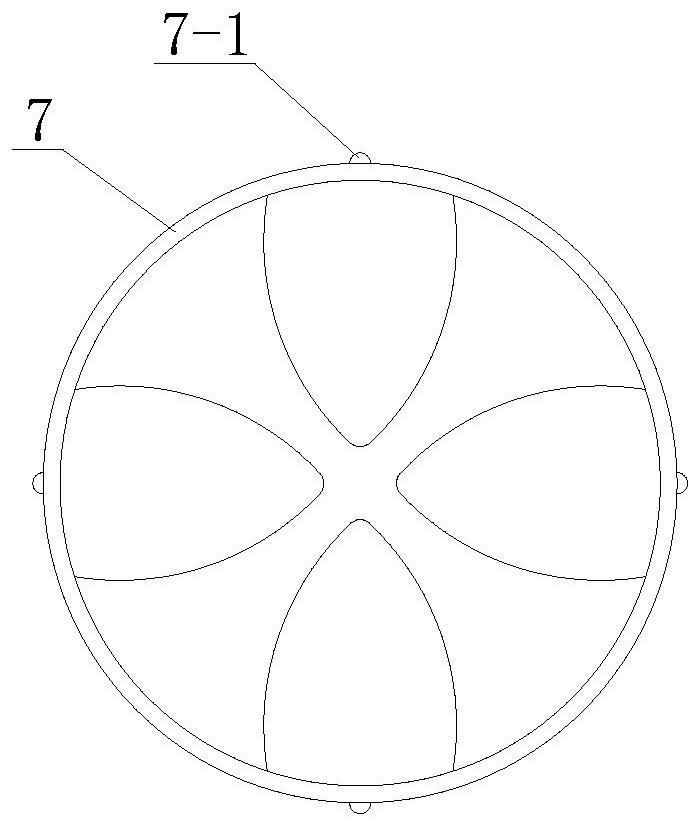

[0030] Such as Figure 1~3 As shown, a double-rotor pump-jet propeller includes a rotating shaft 1, a housing 4, a front end cover 11 and a tail end cover 13. The rotating shaft 1 is hollow and has a trumpet-like structure, and includes a large end portion 1-11, The small end portion 1-3 and the gradual change portion 1-2 connecting the large end portion 1-1 and the small end portion 1-3, the inner cavity of the large end portion 1-1 is fixedly equipped with a first propeller 7; the rotating shaft 1 The bearing 5 is movably connected to the end caps on both sides of the housing 4, and the side of the bearing 5 is provided with a sealing assembly 19; a first power drive device is fixed between the housing 4 and the rotating shaft 1, and the first power drive The device includes a motor stator 3 and a motor rotor 2, the motor rotor 2 is fixed on the gradual change part 1-2 of the rotating shaft 1; the motor stator 3 is fixed on the housing, and provides an axial rotating magneti...

Embodiment 2

[0034] Such as Figure 4~6 As shown, a double-rotor pump-jet propeller includes a rotating shaft 1, a housing 4, a front end cover 11 and a tail end cover 13. The rotating shaft 1 is hollow and has a trumpet-like structure, and includes a large end portion 1-11, The small end portion 1-3 and the gradual change portion 1-2 connecting the large end portion 1-1 and the small end portion 1-3, the inner cavity of the gradual change portion 1-2 is fixedly equipped with a first propeller 7; the rotating shaft 1 passes through The magnetic bearing 5 is movably connected in the end caps on both sides of the housing 4, and a first power driving device is fixed between the housing 4 and the rotating shaft 1, and the first power driving device includes a motor stator 3 and a motor rotor 2, The motor rotor 2 is fixed on the gradual change part 1-2 of the rotating shaft 1; the motor stator 3 is fixed on the housing, providing an axial rotating magnetic field for the motor rotor 2, driving t...

Embodiment 3

[0038] Such as Figure 7 As shown, a traveling tool includes a body 21 and any one of the dual-rotor jet pump propellers 20 mentioned in the above embodiments, the first support frame 17 of the dual-rotor jet pump propeller 20 is integrated with the body 21 Designed, fixed on the body 21, the connecting rod 10 is connected with the second power drive device in the body 21 to provide rotational power, the main propulsion force in the navigation process, the second power drive device is an internal combustion engine 22; in order to improve the submarine's For balance, the casing 4 of the dual-rotor jet pump propeller 20 is provided with hydrofoils 23; in order to further reduce the noise during driving, sound-absorbing materials can be laid on the casing 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com