Diatom ooze sponge ground mat and preparation method thereof

A mud sponge and diatom mud technology, applied in chemical instruments and methods, carpets, laminations, etc., can solve the problems of user inconvenience, use, and lack of finesse, and achieve improved comfort, simple and easy-to-control processes, and enhanced water absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

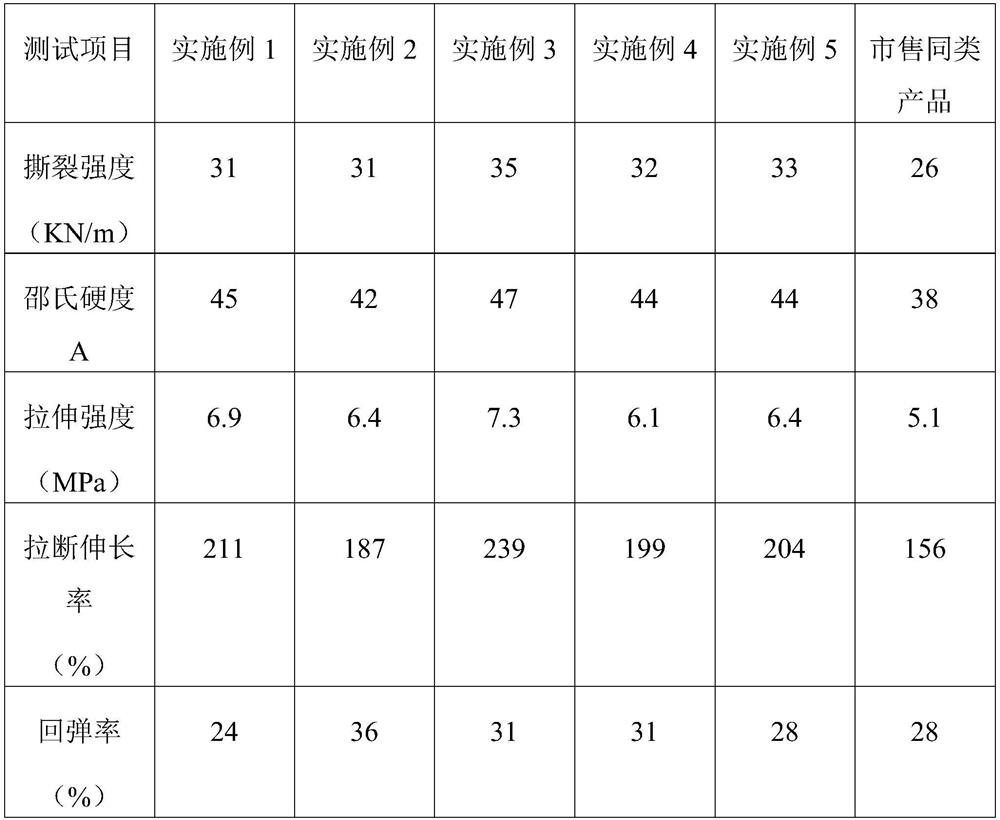

Examples

Embodiment 1

[0029] The present embodiment provides a kind of preparation method of diatom ooze sponge floor mat, comprises the steps:

[0030] (1) Mix 300g of diatomite (800 mesh particle size), 2500g of diisocyanate, and 2500g of polyether, and stir and preheat at 20°C and 60r / min for 30min to obtain mixture a;

[0031] (2) Mix 400g silicone oil and 100g stannous octoate at 40r / min, and stir to obtain mixture b;

[0032] (3) The mixture a described in step (1) and the mixture b obtained in step (2) were stirred and reacted at 100 r / min for 5 minutes to obtain reactant c;

[0033] (4) Pour the reactant c obtained in step (3) into the mold, solidify at 60°C for 30 minutes, and obtain a middle-layer diatom mud sponge after molding;

[0034] (5) Compound acrylic fiber fabric on the upper and lower surfaces of the diatom mud sponge obtained in step (4), the weight ratio of the bottom acrylic fiber fabric, the middle layer diatom mud sponge and the surface layer acrylic fiber fabric is 1:4:1,...

Embodiment 2

[0036] The present embodiment provides a kind of preparation method of diatom ooze sponge floor mat, comprises the steps:

[0037] (1) Mix 500g of diatomite (1000 mesh particle size), 3000g of diisocyanate and 3000g of polyether, and stir and preheat at 25°C and 80r / min for 30min to obtain mixture a;

[0038] (2) Mix 600g silicone oil and 200g stannous octoate under the condition of 60r / min, and stir to obtain mixture b;

[0039] (3) Stirring and reacting the mixture a described in step (1) and the mixture b obtained in step (2) for 10 minutes under the condition of 150 r / min to obtain reactant c;

[0040] (4) Pour the reactant c obtained in step (3) into the mold, solidify at 70°C for 40 minutes, and obtain a middle-layer diatom mud sponge after molding;

[0041] (5) Compound acrylic fabric on the upper and lower surfaces of the diatom mud sponge obtained in step (4), the weight ratio of the bottom acrylic fabric, the middle diatom mud sponge and the surface acrylic fabric i...

Embodiment 3

[0043] The present embodiment provides a kind of preparation method of diatom ooze sponge floor mat, comprises the steps:

[0044] (1) Mix 400g of diatomaceous earth (900 mesh particle size), 2750g of diisocyanate, and 2750g of polyether, and stir and preheat at 22°C and 70r / min for 30min to obtain mixture a;

[0045] (2) Mix 500g silicone oil and 150g stannous octoate under the condition of 50r / min, and stir to obtain mixture b;

[0046] (3) The mixture a described in step (1) and the mixture b obtained in step (2) were stirred and reacted at 125 r / min for 7.5 minutes to obtain reactant c;

[0047] (4) Pour the reactant c obtained in step (3) into the mold, solidify at 65°C for 35 minutes, and obtain a middle-layer diatom mud sponge after molding;

[0048] (5) Compound acrylic fabric on the upper and lower surfaces of the diatom mud sponge obtained in step (4), the weight ratio of the bottom acrylic fabric, the middle diatom mud sponge and the surface acrylic fabric is 2:5:2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com