Stand column shaping device of fan stand column automatic machining equipment and technology thereof

A shaping device and automatic processing technology, applied in metal processing equipment, feeding device, positioning device, etc., can solve the problems of damage to the inner tube, the use of the outer tube and the inner tube that affect the column, and processing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

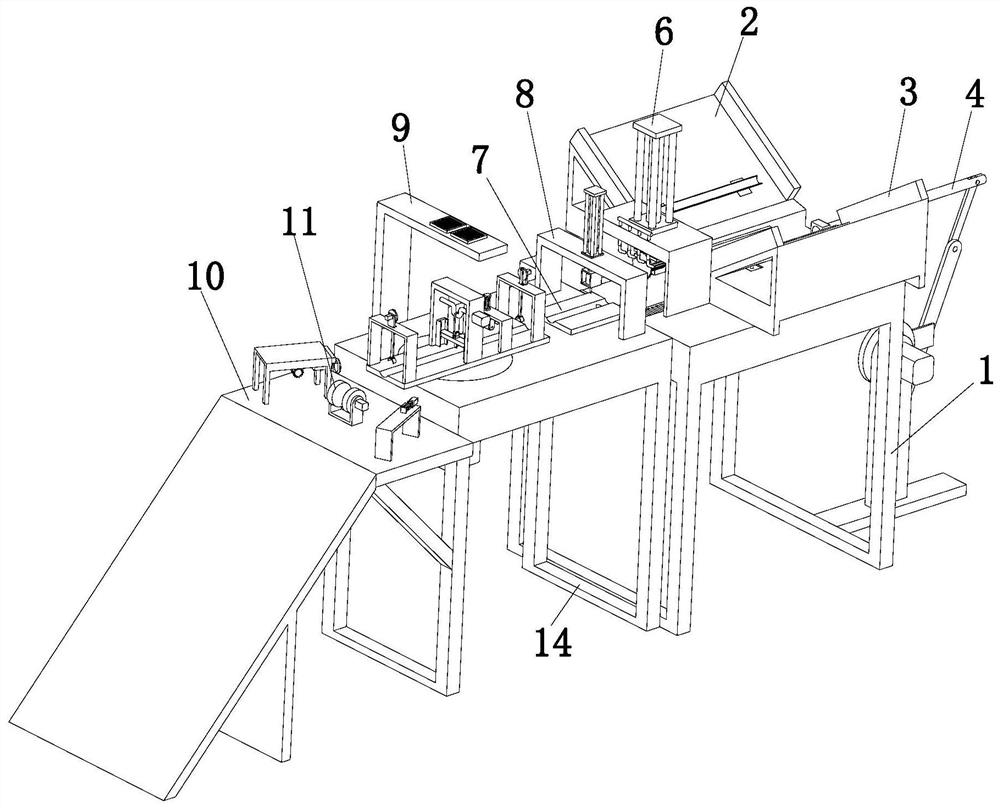

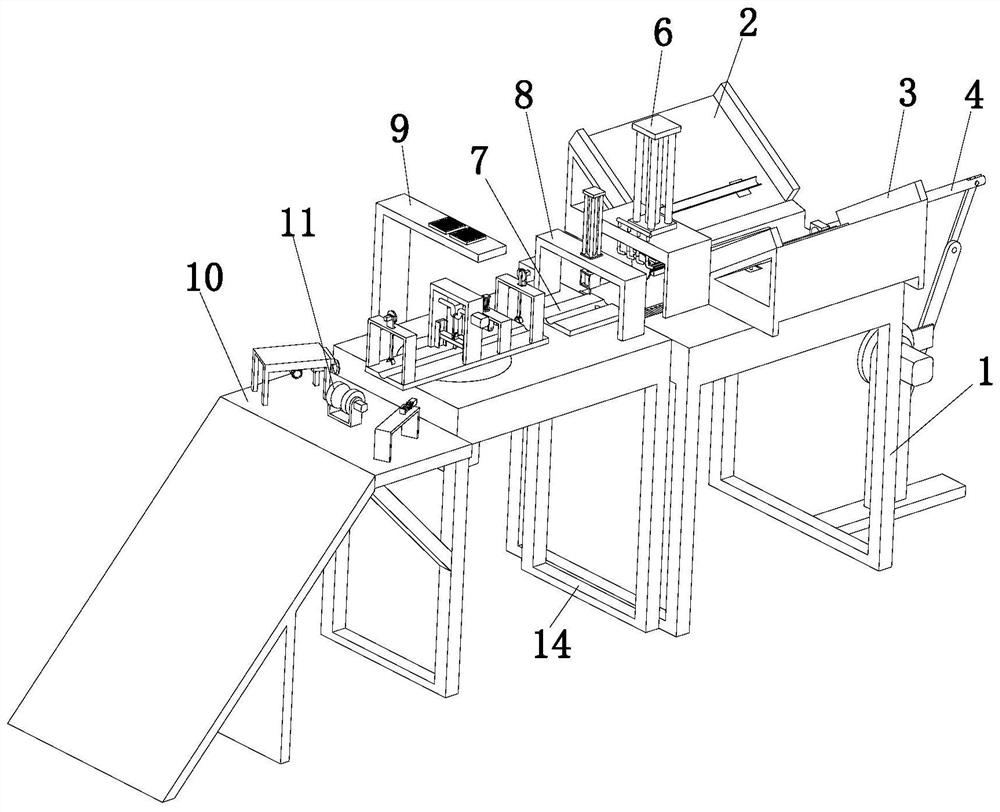

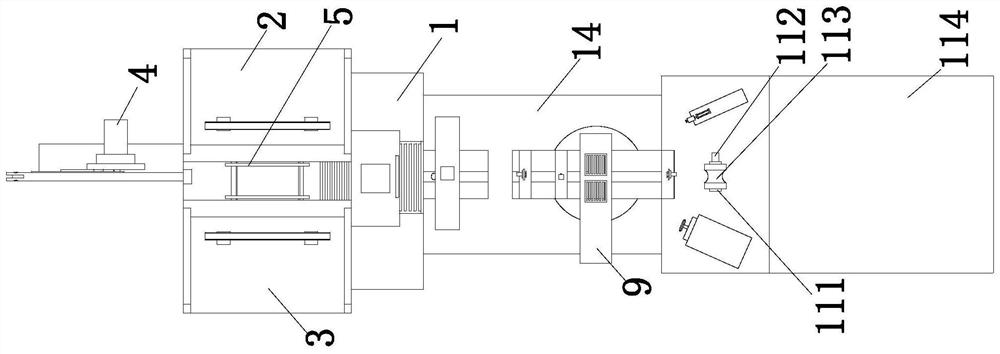

[0045] Combine below Figure 1 to Figure 15 As shown, the embodiment of the present invention provides an automatic processing equipment for a fan column, including a mounting frame 1, an outer tube column feeding device 2, an inner tube column feeding device 3, a column feeding moving device 4, a column fixing device 5, The column cutting device 6, the column moving device 7, the column punching device 8, the support frame 14, the column shaping device 9, the blanking fixing frame 10 and the column blanking device 11, the mounting frame 1 is arranged vertically, and the outer The tube column feeding device 2 and the inner tube column feeding device 3 are symmetrically arranged on the top of the mounting frame 1, the column feeding moving device 4 is arranged on the side of the mounting frame 1, and the column feeding moving device 4 and the mounting frame 1 are arranged. Sliding fit, the column fixing device 5 is arranged on the mounting frame 1 and the column fixing device 5...

Embodiment 2

[0066] The process of the column shaping device of the above-mentioned fan column automatic processing equipment comprises the following steps:

[0067]Step 1. Fix the two ends of the inner tube and the outer tube of the fan column: First, after moving the column to the column fixing plate 913, the drive motor 972 works to drive the drive plate 973 to rotate, and the drive plate 973 rotates to drive the drive plate 974. Moving up and down on the fixing frame 971, the driving plate 974 moves downward to drive the column circular plate 975 to move downward, and the two ends of the inner tube and the outer tube placed on the column fixing plate 913 are fixed to prevent the outer tube and the inner tube from being damaged. When the tube is punched and reshaped, the position of the inner tube and the outer tube is offset, which affects the processing of the inner tube and the outer tube;

[0068] Step 2. Double punch the inner tube and the outer tube: Then, when the inner tube and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com