Carton manufacturing device

A technology for making devices and cardboard boxes, applied in paper/cardboard containers, box making operations, packaging, etc., can solve problems such as inability to collect waste materials, and achieve the effects of easy transfer, optimized working environment, and convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

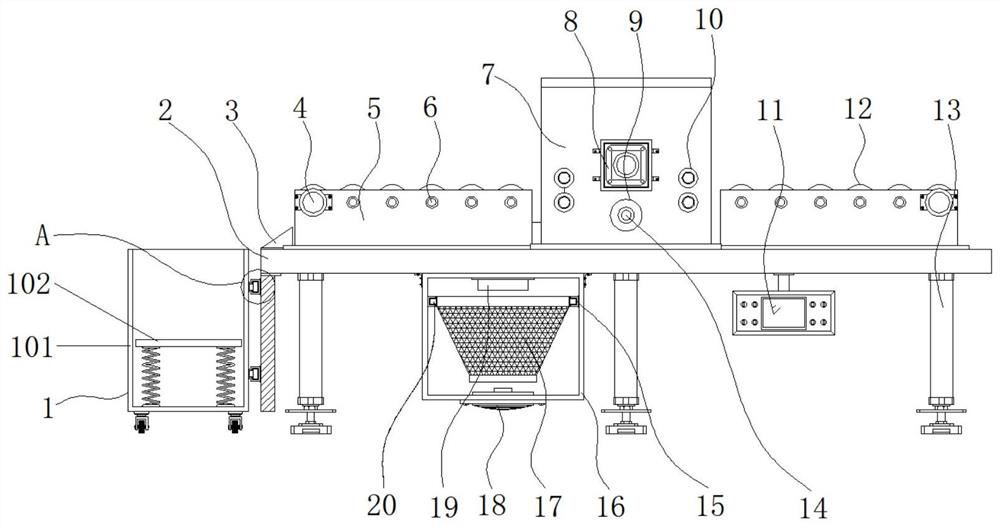

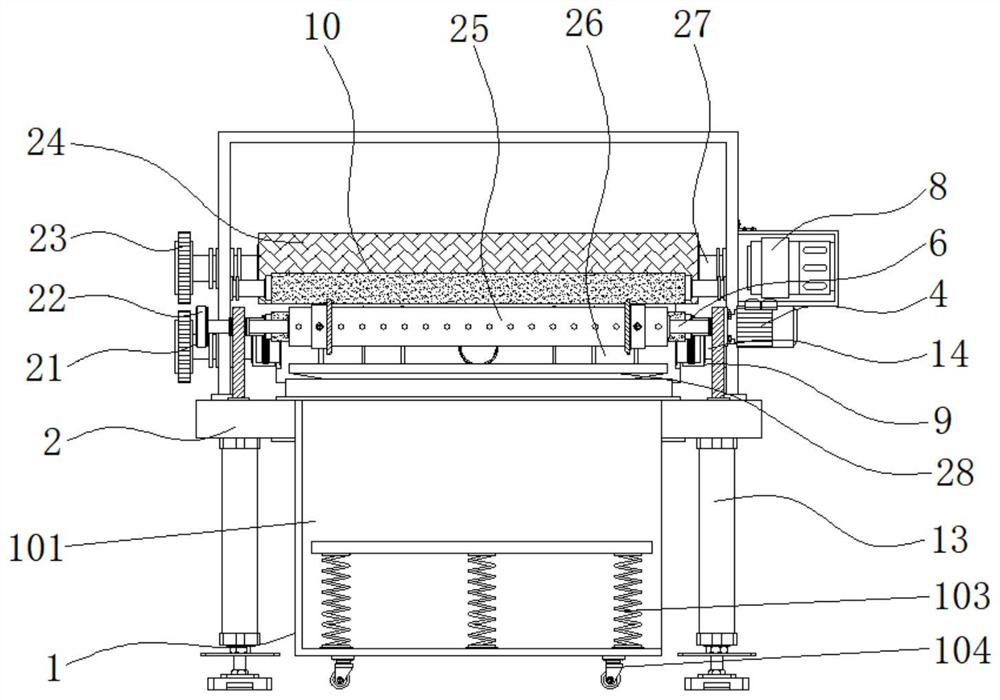

[0035] Example 1: See Figure 1-6 , a kind of cardboard box making device, comprises base plate 2, and support column 13 is evenly fixedly connected with two ends of base plate 2 bottom respectively, and support column 13 is provided with six groups, and one end of base plate 2 is provided with collection structure 1, and the middle position of base plate 2 top A frame body 7 is fixedly connected to the frame body 7, and a second drive motor 8 is fixedly connected to the middle position of one end of the frame body 7. The model of the second drive motor 8 can be Y90S-2, and the middle position between the two ends of the frame body 7 A second drive shaft 27 is movably connected at the top of the bottom plate 2, and one side of the top of the bottom plate 2 is fixedly connected with the material guide plate 3, and the outside of the second drive shaft 27 is fixedly connected with a pressing roller 24, and the bottom between the two ends of the frame body 7 is movable respectivel...

Embodiment 2

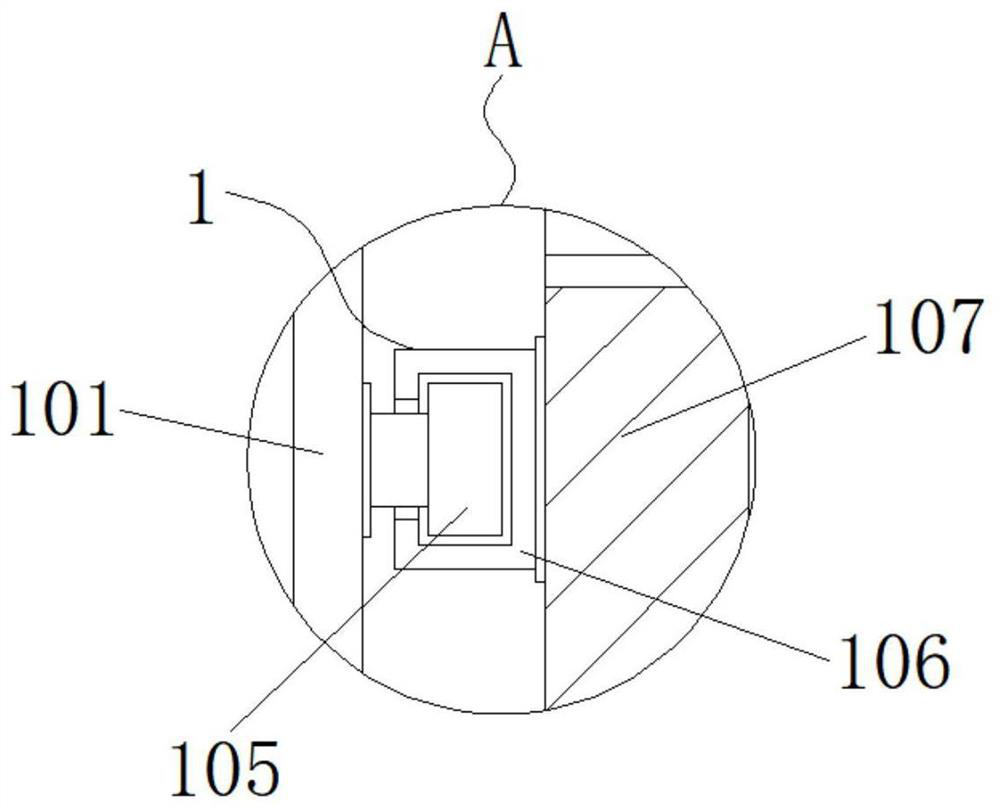

[0039] Embodiment 2: The collection structure 1 is composed of a collection tank 101, a carrier plate 102, a buffer spring 103, a moving wheel 104, a slider 105, a stable chute 106 and a fixed vertical plate 107, and the fixed vertical plate 107 is fixedly connected to the bottom of the bottom plate 2. One side, one side of the fixed vertical plate 107 is provided with a collection tank 101, the four corners of the bottom end of the collection tank 101 are respectively fixedly connected with moving wheels 104, the inside of the collection tank 101 is provided with a carrier plate 102, and the inside bottom of the collection tank 101 The buffer springs 103 are evenly and fixedly connected to both sides, and the tops of the buffer springs 103 are respectively fixedly connected to the bottom of the carrier plate 102, the two ends on one side of the collection tank 101 are fixedly connected to the sliders 105 respectively, and the two ends on the side of the fixed vertical plate 107...

Embodiment 3

[0043] Embodiment 3: The assembly and disassembly structure 9 is composed of an adjustment plate 901, a mounting groove 902, a connecting bolt 903, a connecting hole 904 and a connecting block 905. The mounting grooves 902 are respectively fixedly connected to one end of the connecting shaft 14, and the connecting blocks 905 are respectively fixedly connected to the The two ends of the processing plate roller 26 and the tops of the mounting grooves 902 are respectively movably connected with the adjusting discs 901, the tops of the mounting grooves 902 are respectively plugged with connecting bolts 903, and the inside of the connecting block 905 is respectively provided with connecting holes 904 and connecting bolts 903. The top ends of the connecting pins respectively pass through the interior of the adjusting plate 901, and the bottom ends of the connecting bolts 903 respectively pass through the interior of the connecting hole 904;

[0044] The inside of the adjustment disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com