Metallic paint coating and preparation method thereof

A metal paint and coating technology, applied in the direction of metal-free paint, coating, polyurea/polyurethane coating, etc., can solve the problem that the coating cannot take into account the metal texture and low price, and achieve convenient construction and uniform coating The effect of stability and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Embodiments of the present invention provide a method for preparing a metallic paint coating on the one hand, which is characterized in that it includes the following steps:

[0040] S01: coating a primer layer on the base material, the thickness of the primer layer is 0.2mm-0.5mm;

[0041] S02: Coating a metal paint layer on the primer layer, the metal paint is composed of water-based polyurethane and metal copper powder, and the mass ratio of the water-based polyurethane and metal copper powder is 3:7 to 3:10, so The thickness of the metal paint layer is not less than 0.5mm;

[0042] S03: drying and treating the metallic paint layer;

[0043] S04: Polishing the metal paint layer;

[0044] S05: Blackening the polished metal paint layer;

[0045] S06: performing oxidation treatment on the blackened metal paint layer;

[0046] S07: Coating a transparent protective paint layer on the metal paint layer after the oxidation treatment, the thickness of the transparent pro...

Embodiment 1

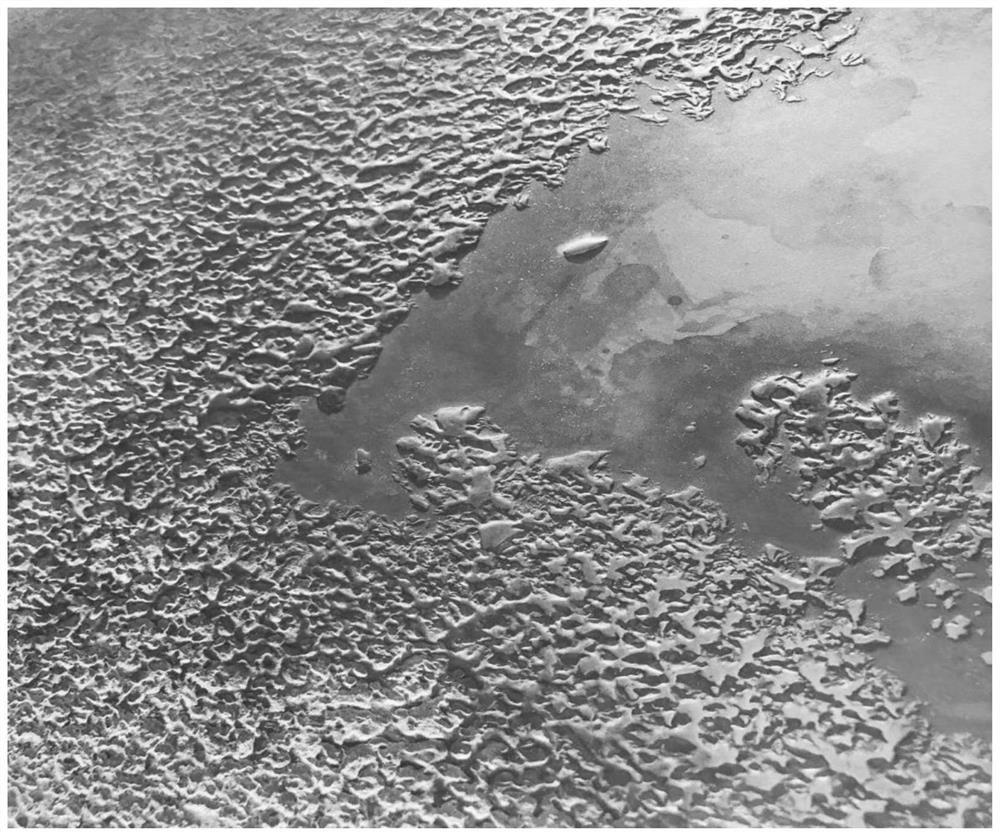

[0063] Preparation method of non-oxidized metal paint coating

[0064] S01: coating a water-based polyurethane paint primer layer on the base material, the thickness of the primer layer is 0.2mm;

[0065] S02: coating a metal paint layer on the primer layer, the composition of the metal paint is water-based polyurethane and metal copper powder, the mass ratio of the water-based polyurethane and metal copper powder is 3:7, the metal paint layer The thickness is not less than 0.5mm;

[0066] S03: drying and treating the metallic paint layer at 50° C. for 6 hours;

[0067] S04: Polishing the metal paint layer, specifically, using 400# disc sandpaper to polish for the first time;

[0068] Use 800# disc sandpaper for the second grinding;

[0069] Use 600#, 800#, 1200# scouring pads to polish in order to increase the luster;

[0070] S05: Coating a transparent water-based polyurethane protective paint layer, the thickness of the transparent protective layer is 0.2 mm.

[0071] ...

Embodiment 2

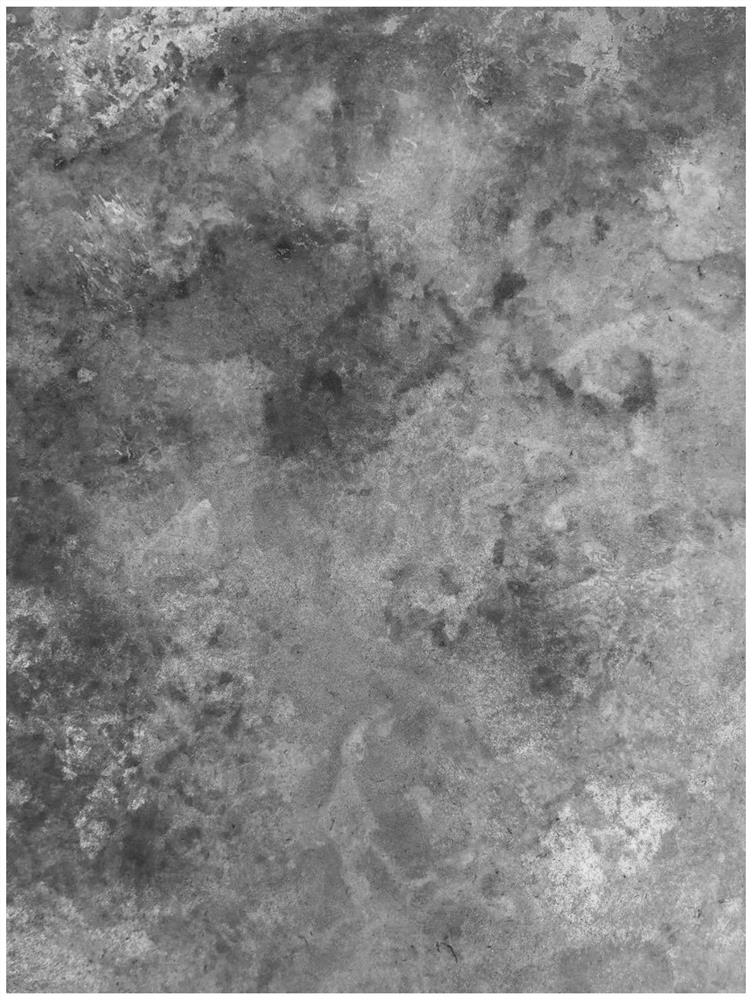

[0073] Preparation method of metallic paint coating oxidation

[0074] S01: Coating a water-based polyurethane primer on the base material and using tools to create a sense of surface texture layering, the thickness of the primer layer is 0.3 mm;

[0075] S02: coating a metal paint layer on the primer layer, the composition of the metal paint is water-based polyurethane and metal copper powder, the mass ratio of the water-based polyurethane and metal copper powder is 3:8, the metal paint layer The thickness is not less than 0.5mm;

[0076] S03: drying and treating the metallic paint layer at 60° C. for 6 hours;

[0077] S04: Polishing the metal paint layer, specifically, using 400# disc sandpaper to polish for the first time;

[0078] Use 800# disc sandpaper for the second grinding;

[0079] Use 600#, 800#, 1200# scouring pads to polish in order to increase the luster;

[0080] S05: blackening the polished metal paint layer with potassium sulfide;

[0081] S06: Perform ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com