A Method for Eliminating Contamination of Fuel Cell Coolant

A fuel cell and fuel cell stack technology, which is applied to fuel cells, circuits, electrical components, etc., can solve problems affecting the performance output of fuel cell stacks, proton exchange membrane pollution, MEA pollution, etc. The effect of heap performance improvement and pollution elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

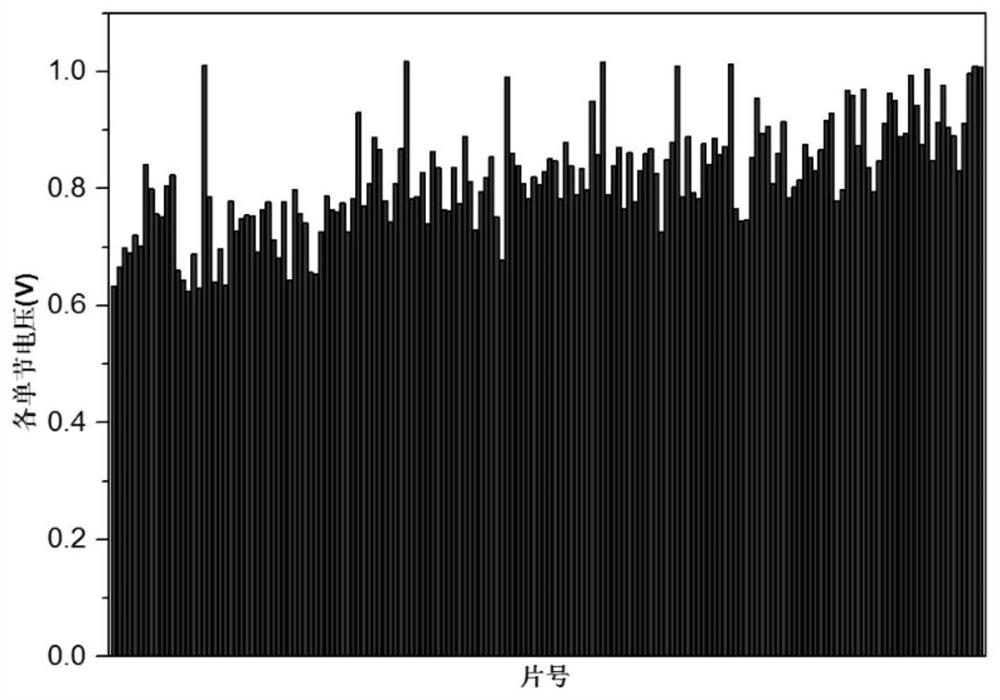

[0025] like figure 1 As shown, when the cooling system accessories (such as the intercooler) fail in the normal operating fuel cell stack, the antifreeze in the cooling liquid circuit enters the fuel cell stack and the single-chip average is detected by the fuel cell voltage inspection system. If the open-circuit voltage is lower than 0.85V, it is determined that the fuel cell stack is contaminated by the coolant, and the following methods are used to eliminate the contamination of the fuel cell coolant. The specific steps are as follows:

[0026] 1. Place the proton exchange membrane fuel cell polluted by the cooling liquid on the test bench, and set the working temperature of the fuel cell to 50-65°C. A certain flow of humidified oxidizing gas is used to purge the cathode and anode of the fuel cell at the same time, and the above steps promote the desorption of anions such as carboxylate adsorbed on the surface of the MEA catalyst, wherein the intake direction of the purge g...

Embodiment 2

[0031] The oxidizing gas described in step (1) is pure oxygen or air, the working pressure is 1kPa, the flow rate is 1*nslpm, n is the number of fuel cell stacks, n≥1, the humidity is 30%, and the purge time is 60min.

[0032] The reducing gas described in step (2) is pure hydrogen, the working pressure is 1kPa, the flow rate is 0.5*n slpm, n is the number of fuel cell stacks, n≥1, the humidity is 30%, and the purging time is 60min .

[0033] Step (3) When the fuel cell stack is activated, the air of the cathode and the hydrogen of the anode are in a metering ratio mode, the metering ratio of the cathode is 1.8, and the metering ratio of the anode is 1.5.

[0034] The rest are the same as in Example 1.

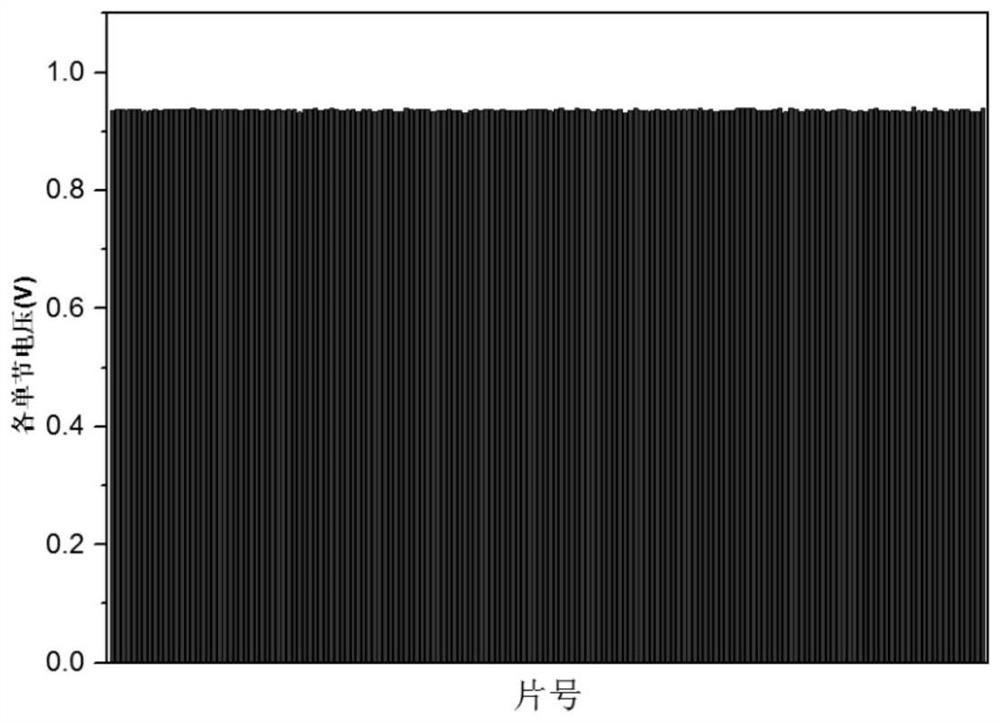

[0035] For the fuel cell stack treated by the above method, the average voltage of a single chip is restored to about 0.94V, and the performance of the stack is improved by about 30-45%.

Embodiment 3

[0037] The oxidizing gas described in step (1) is pure oxygen or air, the working pressure is 80kPa, the flow rate is 2*nslpm, n is the number of fuel cell stacks, n≥1, the humidity is 100%, and the purge time is 30min.

[0038] The reducing gas described in step (2) is pure hydrogen, the working pressure is 80kPa, the flow rate is 1*n slpm, n is the number of fuel cell stacks, n≥1, the humidity is 100%, and the purging time is 30min .

[0039] Step (3) When the fuel cell stack is activated, the air of the cathode and the hydrogen of the anode are introduced in a metering ratio mode, the metering ratio of the cathode is 2.5, and the metering ratio of the anode is 1.5.

[0040] The rest are the same as in Example 1.

[0041] For the fuel cell stack treated by the above method, the average voltage of a single chip is restored to about 0.96V, and the performance of the stack is improved by about 30-45%.

[0042] By adopting the above method, the oxidative gas and reducing gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com