Negative electrode material for zinc-manganese battery and preparation method of negative electrode material

A negative electrode material, zinc-manganese battery technology, applied in battery electrodes, negative electrodes, nanotechnology for materials and surface science, etc., can solve zinc-manganese battery capacity and cycle effect defects, reduce battery capacity and charge and discharge times , the influence of the conductivity of active materials and other issues, to ensure the activity, improve the use and cycle life, and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

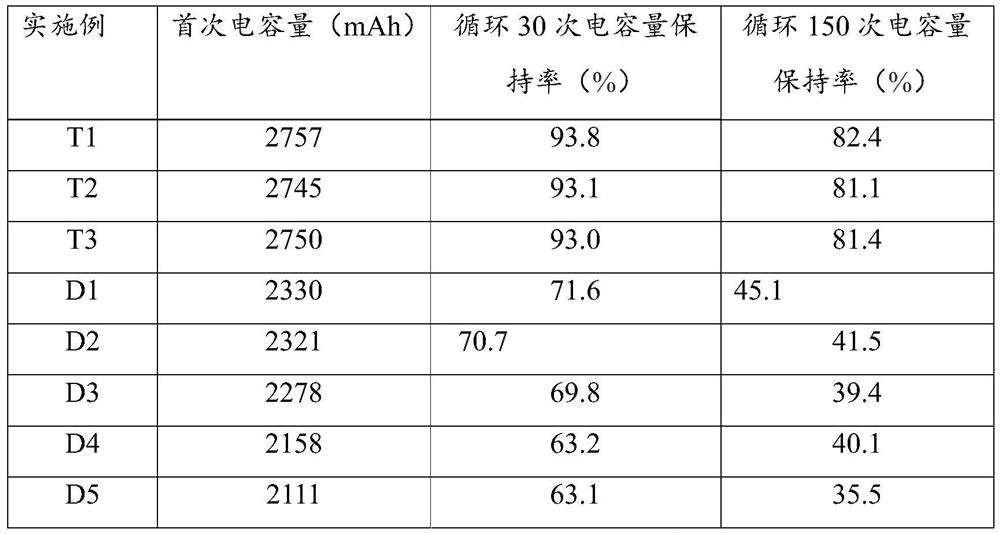

Examples

Embodiment 1

[0045] Embodiment 1 The first aspect provides a kind of zinc-manganese battery negative electrode material, and raw material comprises following parts by weight: 65 parts of nano-zinc powder (average particle diameter 200nm), 5 parts of molybdenum disulfide (average particle diameter 400nm), silicon carbide ( Average particle diameter (400nm) 5 parts, 6 parts of carboxylated graphene quantum dots, 30 parts of modified carbon nanotubes.

[0046] In this embodiment, the modified carbon nanotubes are self-made, and the preparation method includes the following steps: (in parts by weight): (1) Take 1 part of carboxylated carbon nanotubes and add them to 200 parts of deionized water to form a mixed solution, and ultrasonically disperse 2 hours; (2) After the dispersion is complete, add 30 parts of tin chloride pentahydrate and 8 parts of citric acid to the mixed solution, stir and react for 2 hours; (3) heat up to 80 ° C, continue stirring for 21 hours, then heat up to 185°C, stop ...

Embodiment 2

[0053] The specific implementation of this embodiment is the same as that of Example 1, except that: 10 parts of carboxylated graphene quantum dots, 20 parts of modified carbon nanotubes

[0054] The negative electrode material for the zinc-manganese battery prepared in this example is denoted as T2.

Embodiment 3

[0056] The specific implementation of this example is the same as that of Example 1, except that: 50 parts of nano-zinc powder, 10 parts of molybdenum disulfide, and 10 parts of silicon carbide.

[0057] The negative electrode material for the zinc-manganese battery prepared in this example is denoted as T3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com