Detachable floor system connecting joint for modular steel structure and manufacturing method thereof

A technology for connecting nodes and steel structures, applied in the direction of floors, building components, building structures, etc., can solve problems such as insufficient plane stiffness and discontinuity, and achieve the effect of enhancing robustness, facilitating repair, and facilitating disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

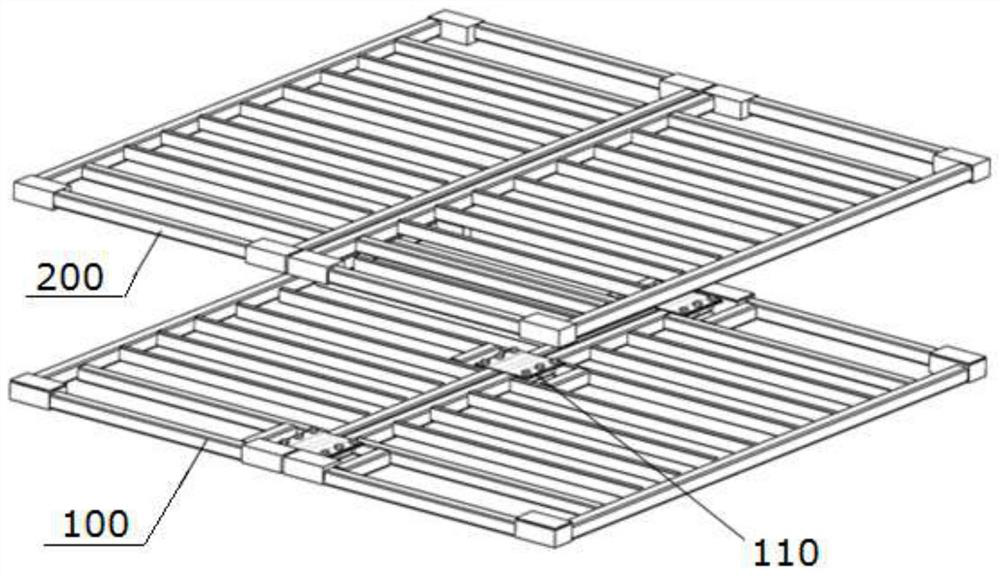

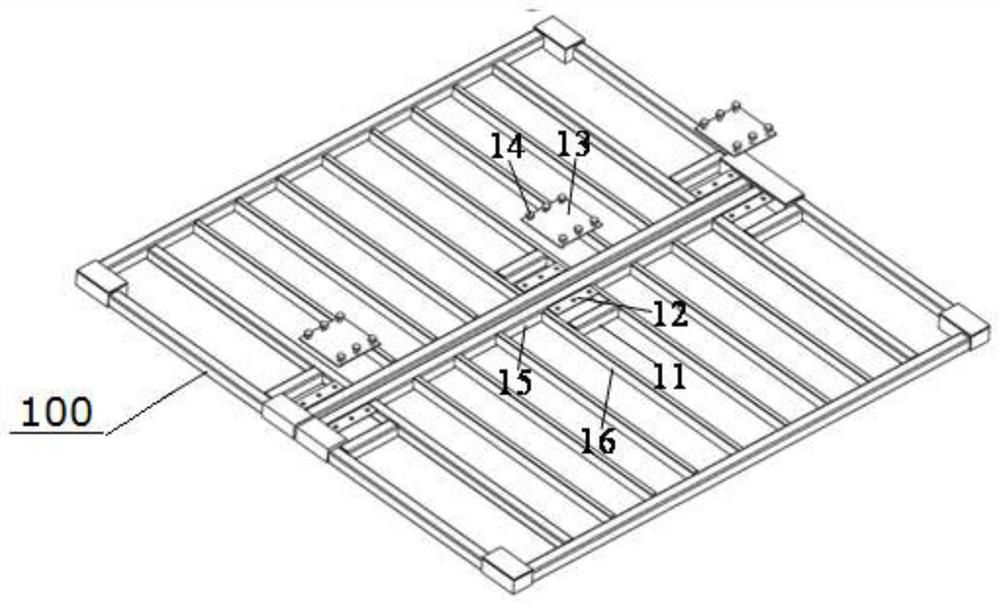

[0029] In one embodiment of the present invention, as Figure 1 to Figure 6 As shown, a detachable floor connection node for a modular steel structure, including a modular ceiling 100, a modular floor 200 and a ceiling beam connection assembly 110; wherein:

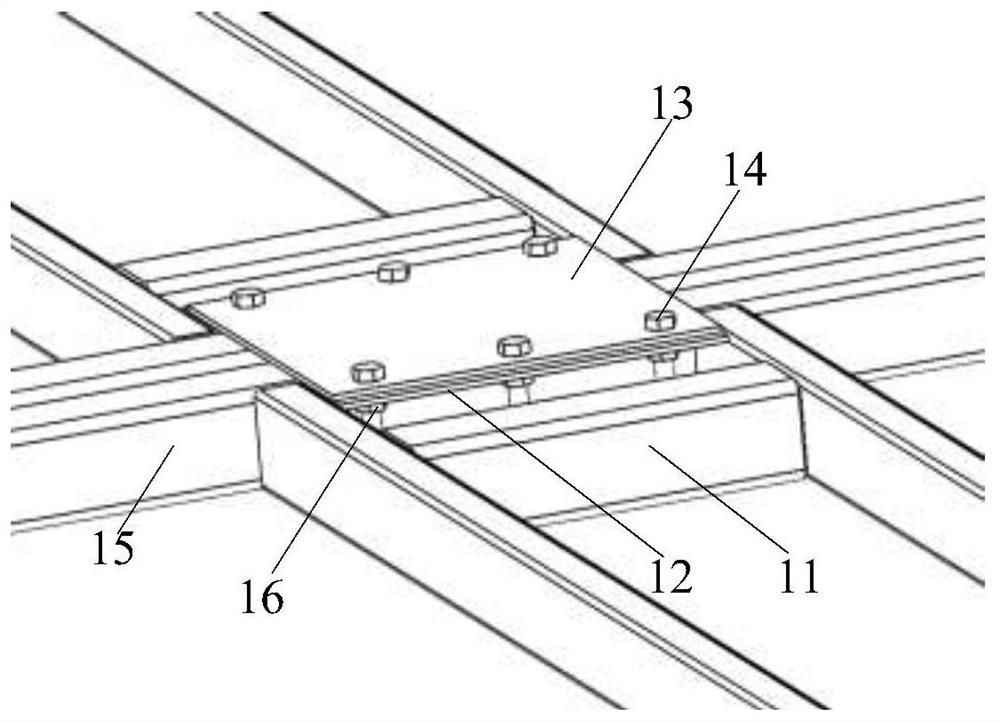

[0030] The ceiling beam connection assembly 110 includes a short beam 11, a beam connection plate 12, a horizontal connection cover plate 13 and high-strength bolts 14, the short beam 11 is pre-welded on the ceiling secondary beam 16, and the beam connection plate 12 is pre-welded Between the ceiling beams 15 and the short beams 11 that are horizontally connected, bolt holes 18 are reserved on the beam connecting plate 12, and the nuts 17 are fixed with a fixing device at the places wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com