Horizontal self-locking connecting joint for modular steel structure and construction method thereof

A technology for connecting nodes and steel structures, which is applied in the direction of building construction and construction, and can solve problems such as the inability to guarantee the integrity of modular building structures, discontinuous floor planes, and insufficient rigidity of structural planes, so as to improve construction speed and quality , easy splicing, and the effect of improving the overall mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

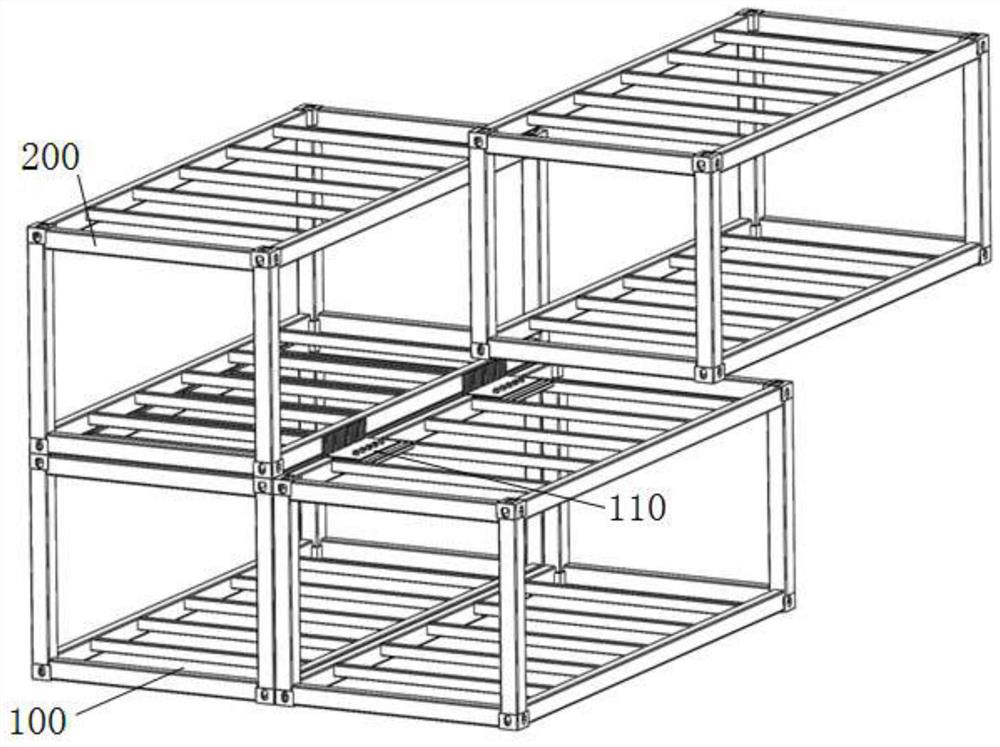

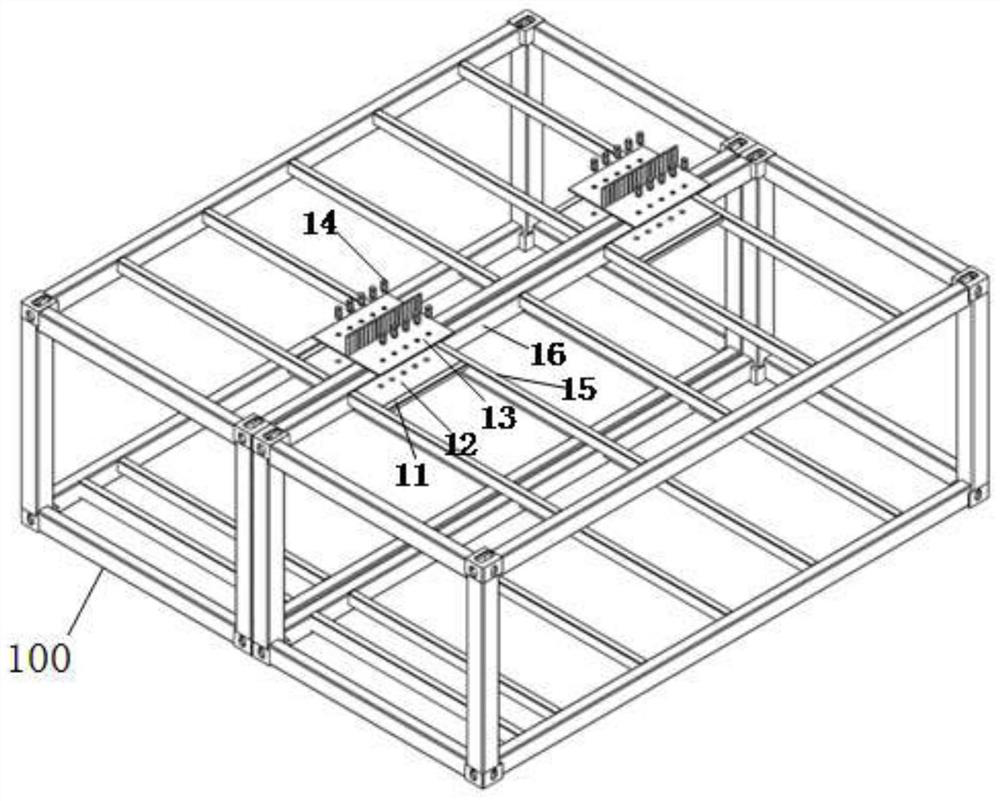

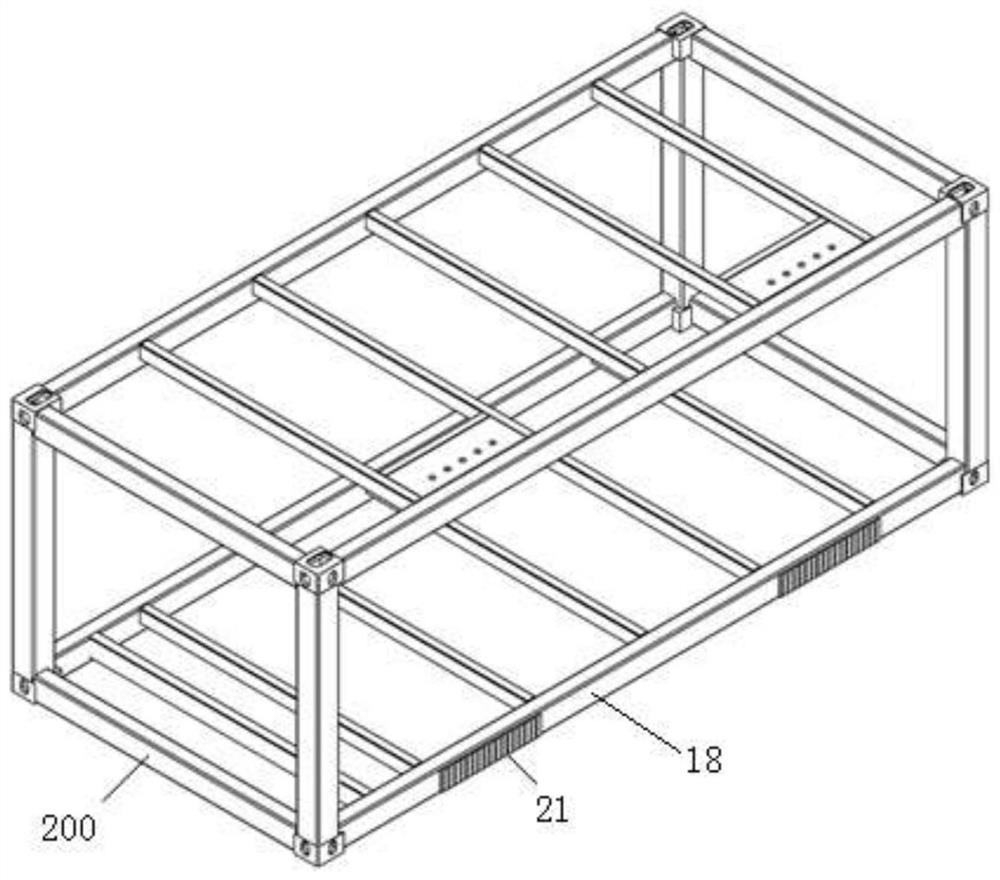

[0032] In one embodiment of the present invention, as Figure 1 to Figure 7 As shown, a horizontal self-locking connection node for modular steel structures, including a lower module unit 100, an upper module unit 200, a floor connection assembly 110 and an interlocking clip 120;

[0033] The floor connection assembly includes short beams 11, beam connection plates 12, T-shaped connectors 13, and high-strength bolts 14;

[0034] Further, the short beam 11 is pre-welded on the ceiling secondary beam 15, the beam connecting plate 12 is pre-welded between the adjacent module unit ceiling beam 16 of the lower module unit 100 and the short beam 11, and the inside of the beam connecting plate 12 is pre-welded. Leave bolt holes 17;

[0035] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com