A method for in-situ growth of refractory superstrong metal single crystal nanowires

An in-situ growth, single crystal nanotechnology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

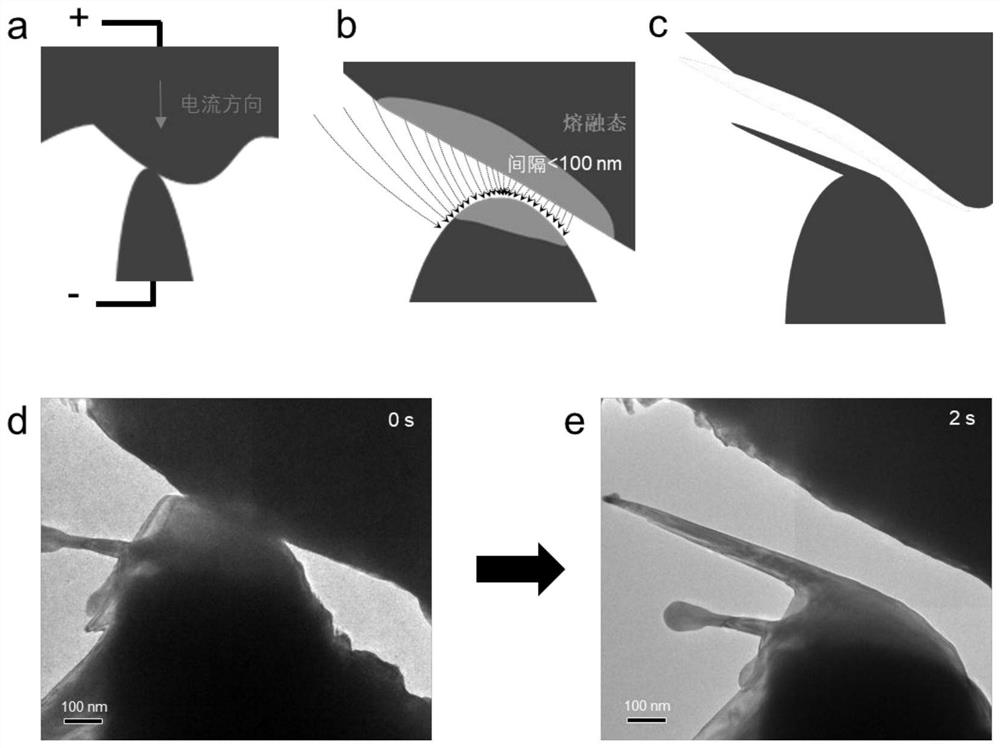

[0025] Concrete steps of the present invention are:

[0026] (1) Install the fracture surface of tungsten metal wire (0.25mm, purity 99.9wt.%) and electrochemically etched tungsten tip respectively on both ends of the in-situ electrical sample rod (Nanofactory STM-TEM holder) and put them into the electron microscope ( Titan 80-300), the radius of curvature of the needle tip is 3×10 -7 m, the radius of curvature of the protruding surface of the sample end is 8×10 -7 m, through the piezoelectric controller (Mains220V), the tip of the needle tip is in contact with the protruding surface of the sample end, and a constant voltage (8V) is applied to generate a current for Joule heating;

[0027] (2) By moving the tungsten tip to reduce the contact area of the two tips, as the contact area decreases, the current density of the contact point increases to melt and disconnect; the electric field enhanced by the curvature of the molten metal between the two disconnected tungsten tips ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com