Graphene modified metal composite material, preparation method and workpiece

A metal composite material, graphene modification technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as graphene and metal materials cannot be uniformly mixed, composite materials with uneven composition, and graphene is easy to agglomerate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

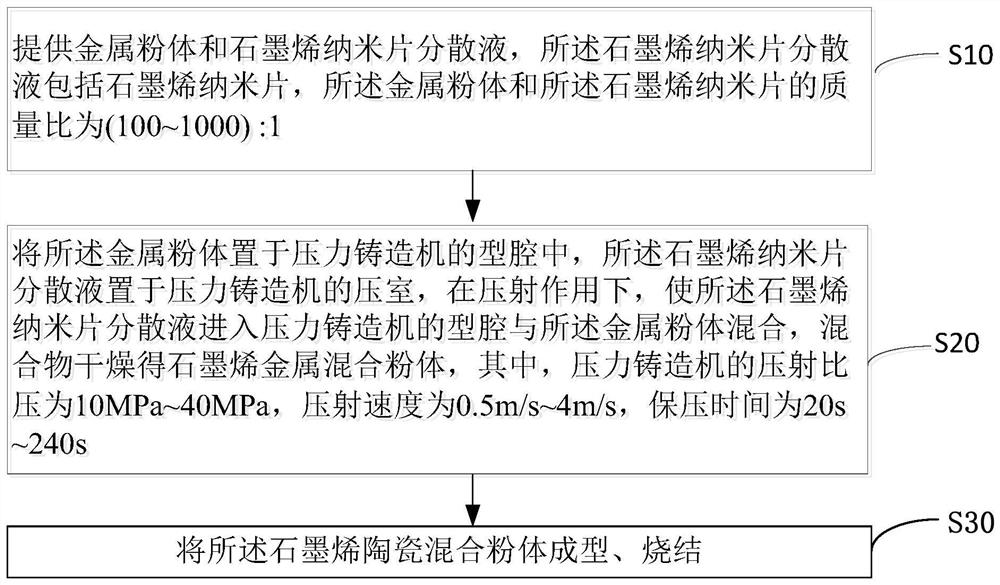

[0027] see figure 1 , the embodiment of the present invention provides a method for preparing a graphene-modified metal composite material, comprising the following steps:

[0028] S10, metal powder and graphene nanosheet dispersion liquid are provided, and described graphene nanosheet dispersion liquid comprises graphene nanosheet, and the mass ratio of described metal powder body and described graphene nanosheet is (100~1000): 1;

[0029] S20, placing the metal powder in the cavity of the die casting machine, placing the graphene nanosheet dispersion in the pressure chamber of the die casting machine, and making the graphene nanosheet dispersion Enter the cavity of the die casting machine and mix with the metal powder, and the mixture is dried to obtain a graphene metal mixed powder, wherein the injection specific pressure of the die casting machine is 10MPa~40MPa, and the injection speed is 0.5m / s~4m / s, the holding time is 20s~240s; and

[0030] S30, forming and sinteri...

Embodiment 1

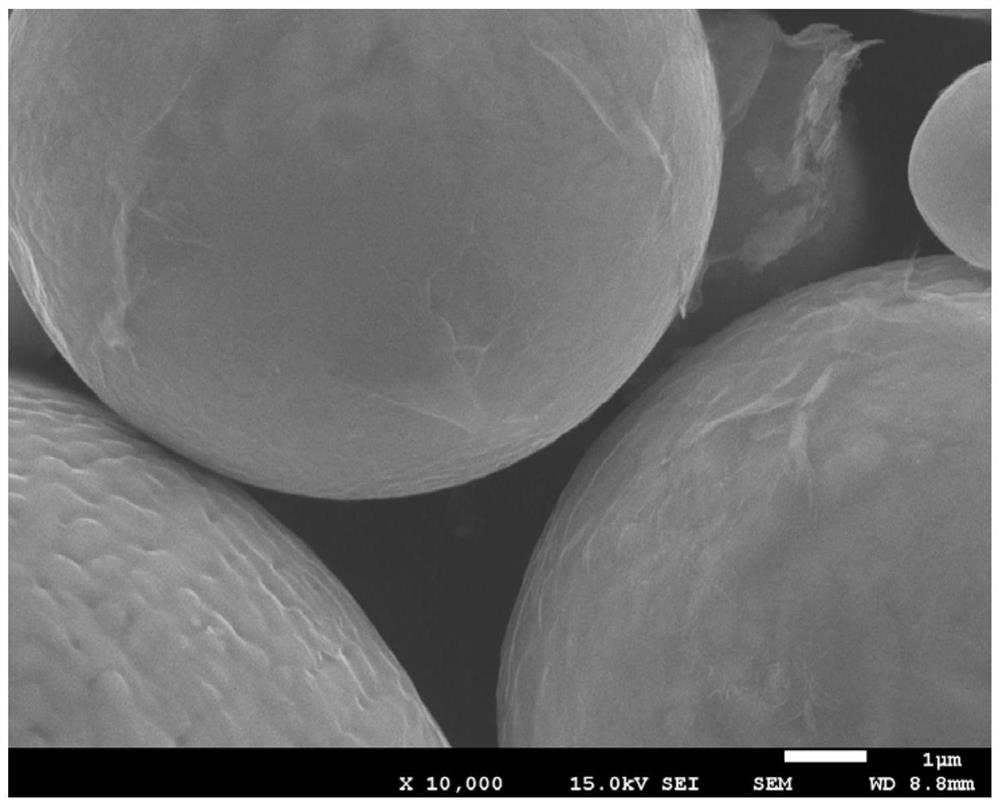

[0069] (1) Provide metal dispersion

[0070] Metal material: spherical pure aluminum powder with a particle size of 30 microns to 60 microns, and an oxygen content of 800 ppm. First solvent: deionized water. First dispersant: polyvinyl alcohol.

[0071] Stir 2g of polyvinyl alcohol in 198g of deionized water at a temperature of 95°C for 1 hour to fully dissolve and place it at room temperature; add 100g of spherical aluminum powder with a particle size of 30 microns to 60 microns into the polyvinyl alcohol aqueous solution, Stir and mix evenly. The mixing time is 3 hours to obtain a spherical pure aluminum powder dispersion. After standing still, pour out the supernatant.

[0072] (2) Preparation of metal powder

[0073] The metal dispersion after removing most of the dispersant in step (1) is put into an oven for drying, and the temperature of the oven is set at 60° C. to obtain a spherical pure aluminum powder with a water content of less than 1%.

[0074] (3) Provide gr...

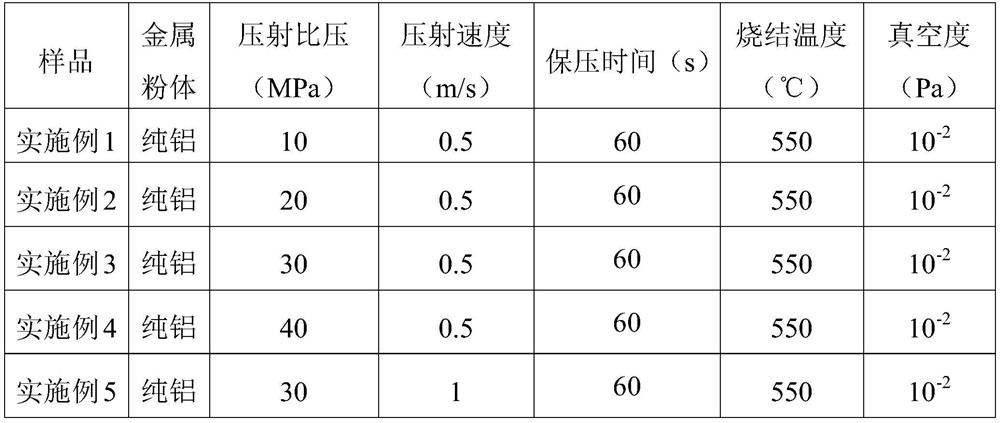

Embodiment 2

[0083] The preparation method is basically the same as in Example 1, except that the specific injection pressure is 20 MPa. Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com