Process for extracting nickel and molybdenum from black shale through acid wet method

A technology of black shale and wet process, applied in nickel sulfate, improvement of process efficiency, molybdenum compound, etc., can solve environmental pollution and extract nickel and molybdenum, and achieve the effect of solving air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

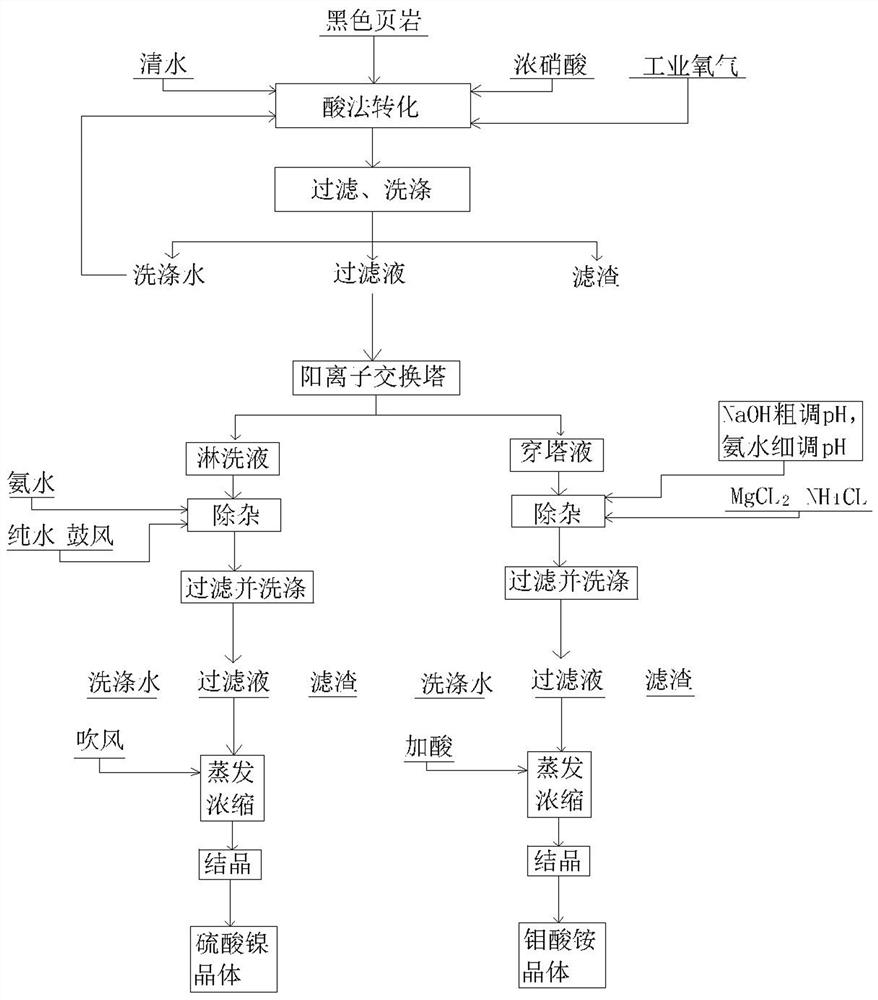

Image

Examples

Embodiment 1

[0024] This embodiment provides a process for extracting nickel and molybdenum from black shale by an acidic wet method.

[0025] 1) Preparation: Raw materials: 100 kg of black shale concentrate, ingredients: Mo content is about 5%, Ni content is about 2.5%. In this embodiment, the particle size of the black shale is all above 100 mesh, that is, the particle size of the particles is smaller than the particle size corresponding to 100 mesh.

[0026] 2) Wet conversion: add 100L of water to the container, heat it to 80-10°C under stirring conditions, and slowly feed excess industrial oxygen into it. (Volume: Weight) 1:1. Finally, pump concentrated nitric acid into the system at a rate of 200 to 300mL / h; at this time, the temperature, gaseous foam, and liquid line position in the system have changed dramatically, and attention should be paid to adding water at any time to adjust the pH value from middle to middle. The sex gradually decreased to between pH 0 and 0.5, and remained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com