High-impact-resistance automobile front bumper and injection molding process thereof

A front bumper, impact-resistant technology, applied in other household appliances, household components, applications, etc., can solve the problems of poor impact resistance and energy absorption, endangering the safety of passengers, and bumper deformation, etc., to achieve impact resistance. The effect of strong, good surface gloss and excellent protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

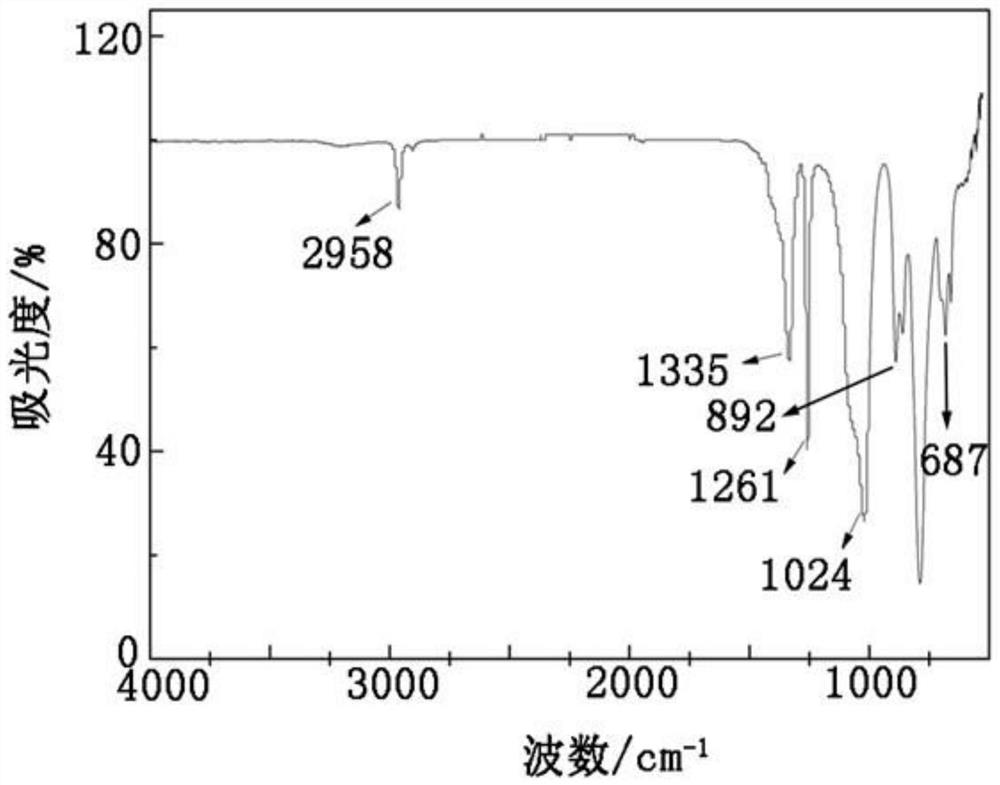

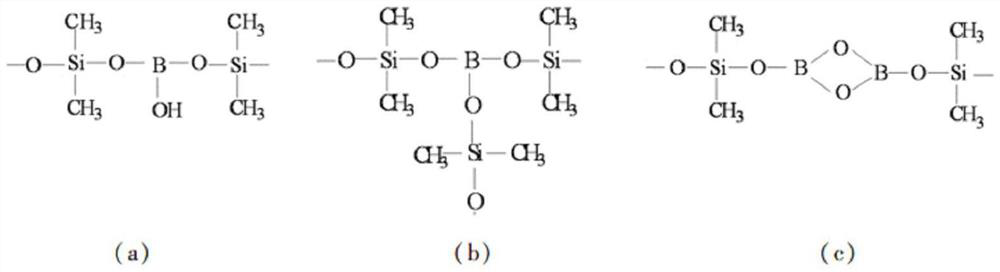

[0039] The preparation method of anti-impact thickening glue is:

[0040] A1. Put a certain amount of boric acid in a heating tank, heat at 160°C for 2 hours, then add an appropriate amount of hydroxy silicone oil and silicon dioxide, stir evenly and put it in an oven for baking;

[0041] A2. Take it out after baking for 2-4 hours. After the product is cooled to a suitable temperature, add a certain amount of isopropanol, mix evenly, and after cooling completely, you can make an impact-resistant thickening glue.

Embodiment 1

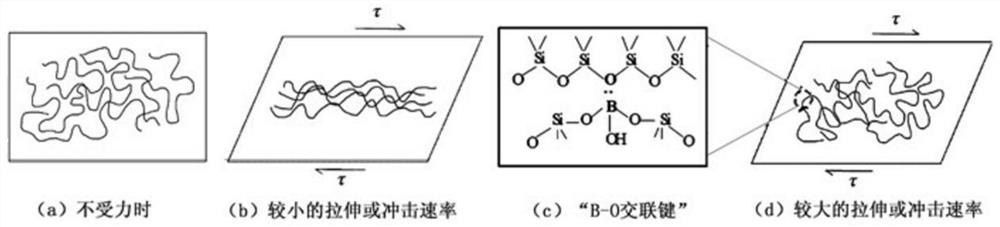

[0043] A kind of automobile front bumper with strong impact resistance designed by the present invention, the raw materials of the automobile front bumper are composed by weight: 60 parts of polypropylene material, 30 parts of composite mineral material, 15 parts of polyborodimethylsiloxane 10 parts of auxetic material, 20 parts of anti-impact thickening glue, 5 parts of plasticizer, 10 parts of nanomaterials;

[0044] The composite mineral material is composed of 30 parts by weight of talcum powder, 25 parts of mica powder, 15 parts of precipitated barium sulfate, 18 parts of wollastonite powder, and 22 parts of calcium carbonate;

[0045] The components of the anti-impact thickening glue are as follows in parts by weight: 40 parts of boric acid, 25 parts of hydroxyl silicone oil, 20 parts of silicon dioxide and 15 parts of isopropanol, wherein the particle size of silicon dioxide is 800mm;

[0046] The nanomaterial is a mixture of nano-titanium dioxide and nano-silicon dioxi...

Embodiment 2

[0048] A kind of automobile front bumper with strong impact resistance designed by the present invention, the raw materials of the automobile front bumper are composed by weight: 100 parts of polypropylene material, 40 parts of composite mineral material, 30 parts of polyborodimethylsiloxane 20 parts of auxetic material, 40 parts of anti-impact thickening glue, 10 parts of plasticizer, 15 parts of nanomaterials;

[0049] The composite mineral material is composed of 40 parts by weight of talcum powder, 30 parts of mica powder, 25 parts of precipitated barium sulfate, 22 parts of wollastonite powder, and 28 parts of calcium carbonate;

[0050] The components of the anti-impact thickening glue are as follows in parts by weight: 50 parts of boric acid, 40 parts of hydroxyl silicone oil, 25 parts of silicon dioxide and 20 parts of isopropanol, wherein the particle size of silicon dioxide is 800mm;

[0051] The nanomaterial is a mixture of nano-titanium dioxide and nano-silicon dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com