Lignin nanoparticles as well as preparation method and application thereof

A nanoparticle and lignin technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of environmental harm and consumption, and achieve the effect of low cost, cost reduction and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

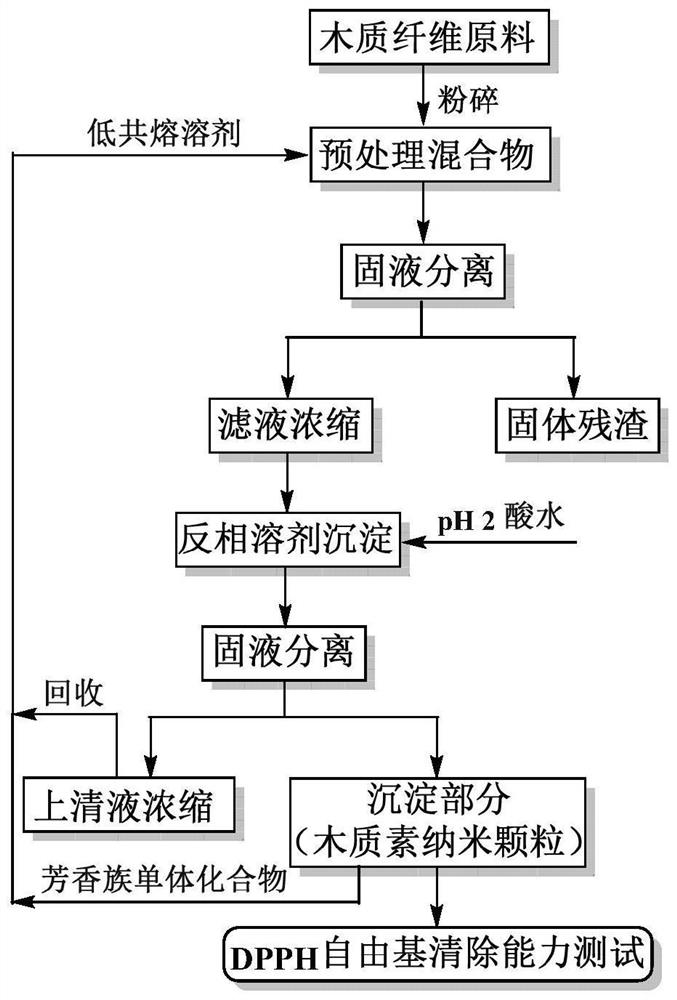

[0059] Such as figure 1 As shown, the present embodiment provides a method for preparing lignin nanoparticles, comprising the following steps:

[0060] Step A, using dragon bamboo biomass (with a lignin content of 22.8wt%) as raw material, air-dried, crushed, and sieved to obtain 40-60 mesh powder, dried in an oven at 60°C for 24 hours for later use, with a moisture content of 8% -12%.

[0061] Step B, mix choline chloride and p-hydroxybenzoic acid at a molar ratio of 3:2, heat in an oil bath at 100°C for 2 hours to obtain a homogeneous and transparent liquid, and store it for future use.

[0062] Step C, mix 4.0g dragon bamboo raw material with 40g choline chloride: p-hydroxybenzoic acid deep eutectic solvent, react the obtained solid-liquid mixture at 120°C for 6h, add 200mL acetone aqueous solution after the reaction is completed, and obtain pretreatment Mixture; the volume ratio of acetone to water in the acetone aqueous solution is 1:1.

[0063] Step D, use vacuum filt...

Embodiment 2

[0069] Such as figure 1 As shown, the present embodiment provides a method for preparing lignin nanoparticles, comprising the following steps:

[0070] Step A, using dragon bamboo biomass (with a lignin content of 22.8wt%) as raw material, air-drying, crushing, and sieving to obtain 40-60 mesh powder, drying in an oven at 60°C for 24 hours for later use, with a moisture content of 8%- 12%.

[0071] Step B, mix choline chloride and p-hydroxybenzoic acid at a molar ratio of 3:2, heat in an oil bath at 100°C for 2 hours to obtain a homogeneous and transparent liquid, and store it for future use.

[0072] Step C, mix 4.0g dragon bamboo raw material with 40g choline chloride: p-hydroxybenzoic acid deep eutectic solvent, react the obtained solid-liquid mixture at 140°C for 4h, add 200mL acetone aqueous solution after the reaction is completed, to obtain pretreatment mixture. The volume ratio of acetone to water in the acetone aqueous solution is 1:1.

[0073] Step D, use vacuum ...

Embodiment 3

[0079] Such as figure 1 As shown, the present embodiment provides a method for preparing lignin nanoparticles, comprising the following steps:

[0080] Step A, using dragon bamboo biomass (with a lignin content of 22.8wt%) as raw material, air-drying, crushing, and sieving to obtain 40-60 mesh powder, drying in an oven at 60°C for 24 hours for later use, with a moisture content of 8%- 12%.

[0081] Step B, mix choline chloride and p-hydroxybenzoic acid at a molar ratio of 3:2, heat in an oil bath at 100°C for 2 hours to obtain a homogeneous and transparent liquid, and store it for future use.

[0082] Step C, mix 4.0g dragon bamboo raw material with 40g choline chloride: p-hydroxybenzoic acid deep eutectic solvent, react the obtained solid-liquid mixture at 160°C for 3h, add 200mL acetone aqueous solution after the reaction is completed, and obtain pretreatment mixture. The volume ratio of acetone to water in the acetone aqueous solution is 1:1.

[0083] Step D, use vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com