Medium-temperature fast-curing single-component epoxy resin system for prepreg and preparation method thereof

A technology of epoxy resin system and epoxy resin matrix, applied in organic chemistry and other directions, can solve the problems of high curing temperature and long curing time, and achieve the effect of long storage period at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

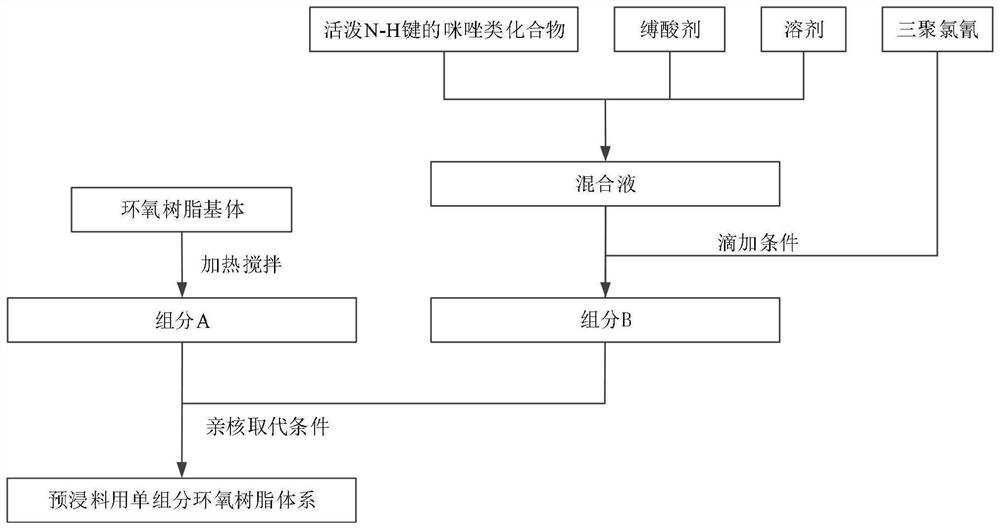

[0024] See figure 1 , the present invention provides a preparation method of a one-component epoxy resin system for prepregs (that is, a medium-temperature rapid curing one-component epoxy resin system for prepregs), comprising: preparing component A, that is, epoxy resin The substrate is heated and stirred; component B is prepared, that is, through the nucleophilic substitution reaction between imidazole compounds containing active N-H bonds and cyanuric chloride, an imidazole latent curing agent containing triazine ring structure is obtained; component A and component Part B is heated, stirred and mixed evenly to obtain a one-component epoxy resin system for prepregs.

[0025] Optionally, the epoxy resin matrix includes at least one of bisphenol A glycidyl ether, novolac epoxy resin, and glycidylamine epoxy resin; the epoxy resin matrix is heated and stirred at a temperature of 50- 120°C.

[0026] Optionally, the one-component epoxy resin system for prepreg includes comp...

Embodiment 1

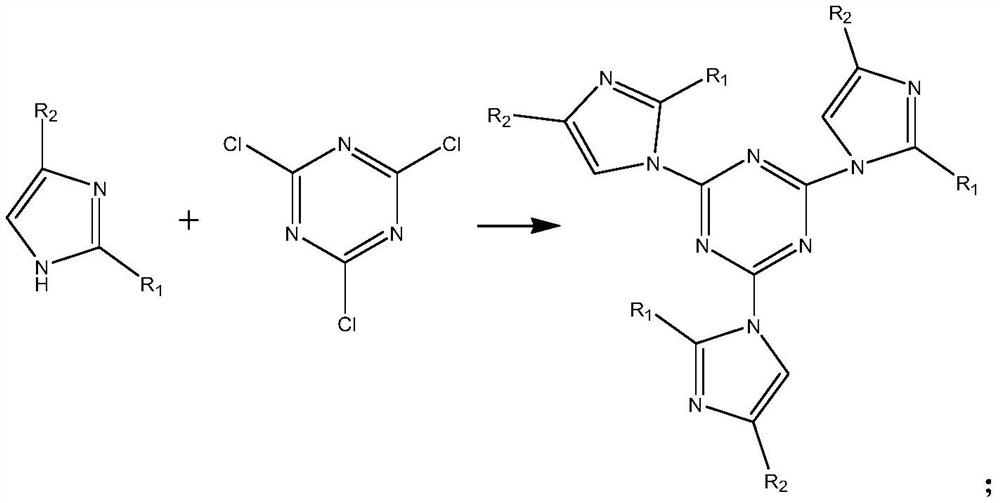

[0045] Select an imidazole latent curing agent containing a triazine ring structure, and its molecular structure is as follows:

[0046] Among them, R 1 and R 2 Both are hydrogen.

[0047] The preparation method of the above-mentioned imidazole latent curing agent containing triazine ring structure, the concrete steps are as follows:

[0048] 1) Add 20.4g of imidazole and 30.3g of triethylamine into a three-necked flask filled with 250ml of tetrahydrofuran, stir at room temperature until the reactants are mixed evenly, and continuously feed nitrogen; dissolve 18.45g of cyanuric chloride in 100ml of tetrahydrofuran , under room temperature, nitrogen, and stirring conditions, add the cyanuric chloride / tetrahydrofuran solution dropwise to the above-mentioned three-necked flask through a constant pressure dropping funnel;

[0049] 2) After the addition of the cyanuric chloride / tetrahydrofuran solution is completed, the temperature in the above-mentioned three-neck flask is ra...

Embodiment 2

[0051] The imidazole latent curing agent containing triazine ring structure has the following molecular structural formula:

[0052] Among them, R 1 for methyl and R 2 for hydrogen.

[0053] The preparation method of the above-mentioned imidazole latent curing agent containing triazine ring structure, the concrete steps are as follows:

[0054] 1) Add 24.6g of 2-methylimidazole and 30.3g of triethylamine into a three-neck flask filled with 200ml of tetrahydrofuran, stir at 50°C until the reactants are mixed evenly, and continue to feed nitrogen; 18.45g of cyanuric chloride Dissolve in 100ml tetrahydrofuran, and add the cyanuric chloride / tetrahydrofuran solution dropwise into the bottle through a constant pressure dropping funnel at 50°C under nitrogen and stirring;

[0055] 2) After the dropwise addition of the cyanuric chloride / tetrahydrofuran solution, raise the temperature in the above-mentioned three-neck flask to 75°C and stir for 4 hours; Stir and wash, then filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com