Polyisocyanate composition with storage stability

A technology of polyisocyanate and isocyanurate, which is applied in the field of polyisocyanate composition, can solve problems such as differences in application performance, and achieve the effect of convenient source and excellent moisture stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

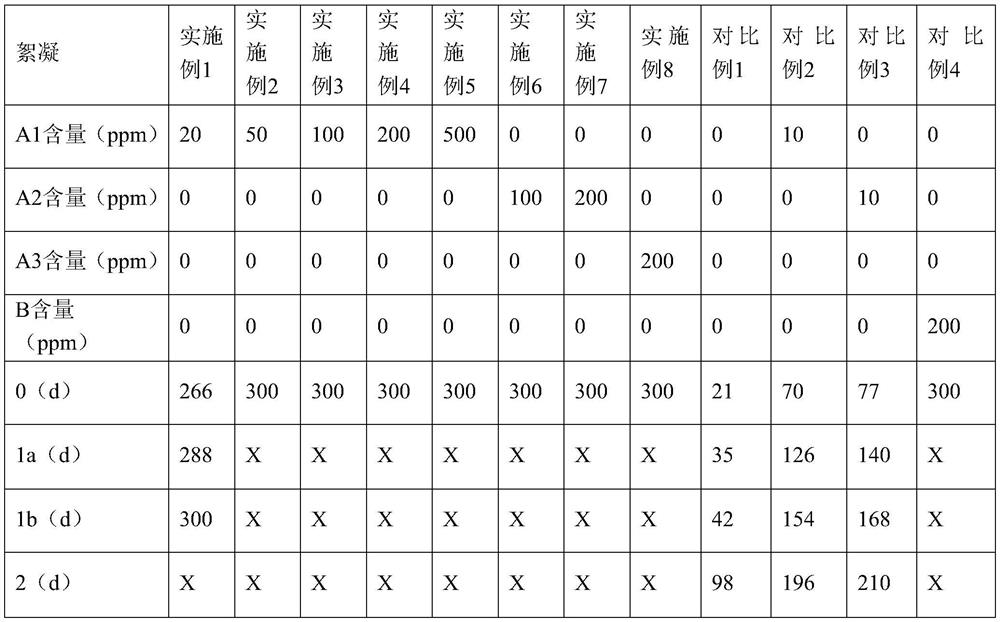

Examples

preparation example Construction

[0058] Preparation of polyisocyanate composition:

[0059] Under nitrogen protection conditions, 800g of hexamethylene diisocyanate was heated and stirred in a 75°C water bath for 1.5h, and then 0.6g of a 20wt% isooctyl alcohol solution of N,N,N-trimethylbenzyl ammonium hydroxide was added ( 150ppm), by regulating and controlling the water bath temperature control reaction temperature is 70 ℃; Distilled twice under conditions of 150°C and 0.4 Torr to obtain a polyisocyanate composition.

[0060] The chromaticity of the obtained polyisocyanate composition was 18 Hazen, the viscosity was 2880 mPa·s (25° C.), the NCO content was 21.8 wt %, and the monomer content was 0.12 wt %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com