A kind of zirconia ceramic material and its preparation method and application

A technology of zirconia ceramics and zirconia, which is applied in the field of ceramic materials, can solve the problems of reduced bending strength of materials, and achieve the effects of small reduction in bending strength, low temperature, and increased volume content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

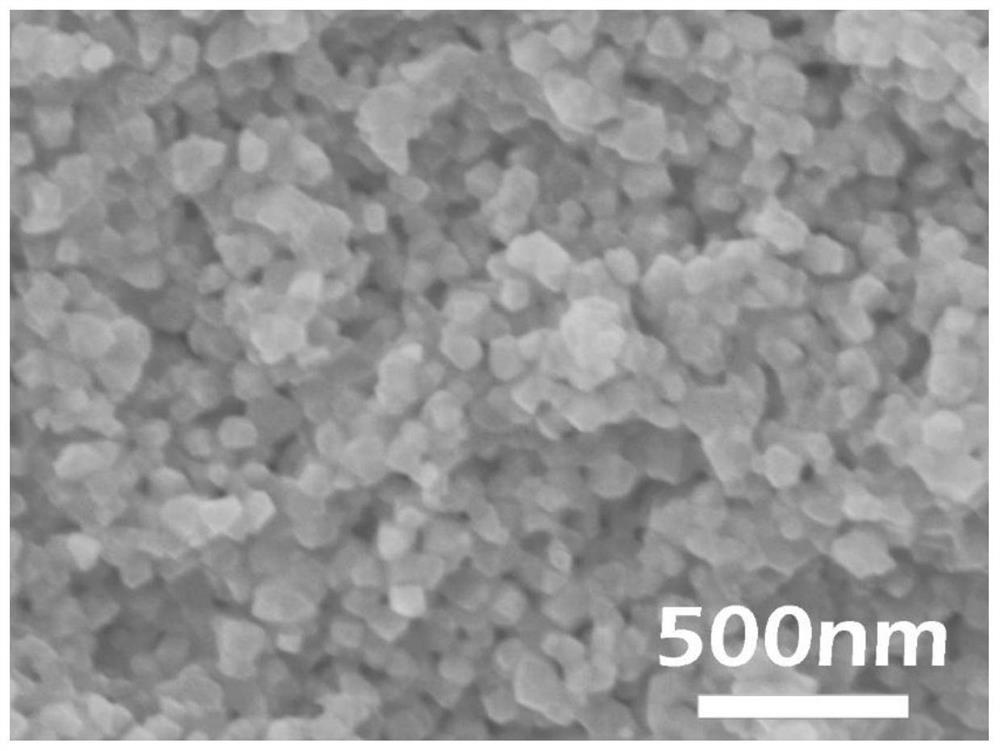

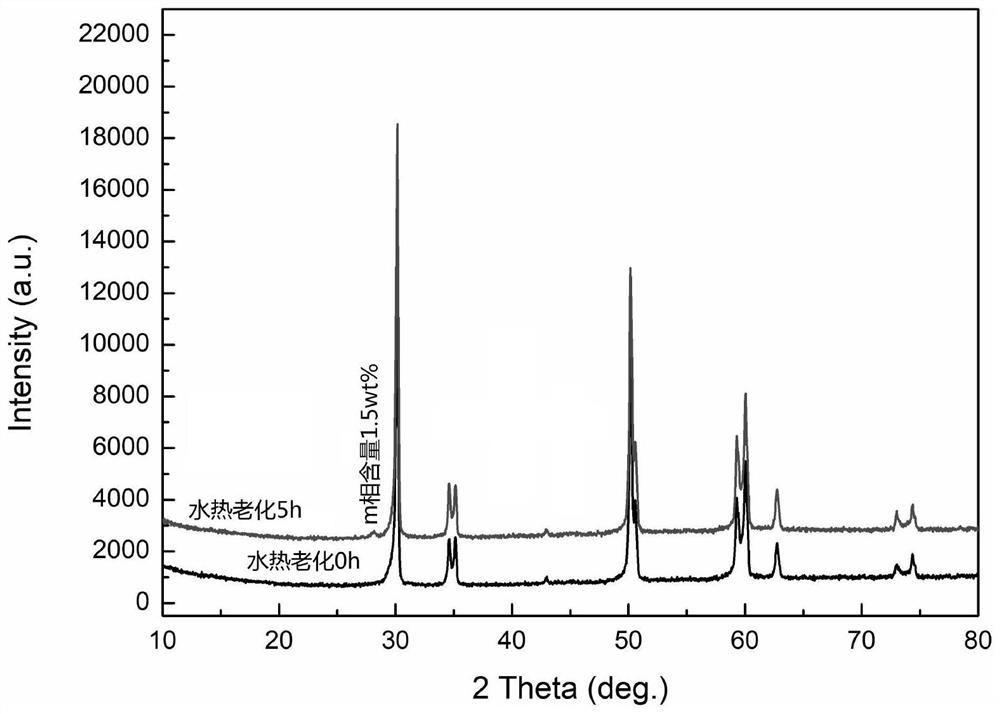

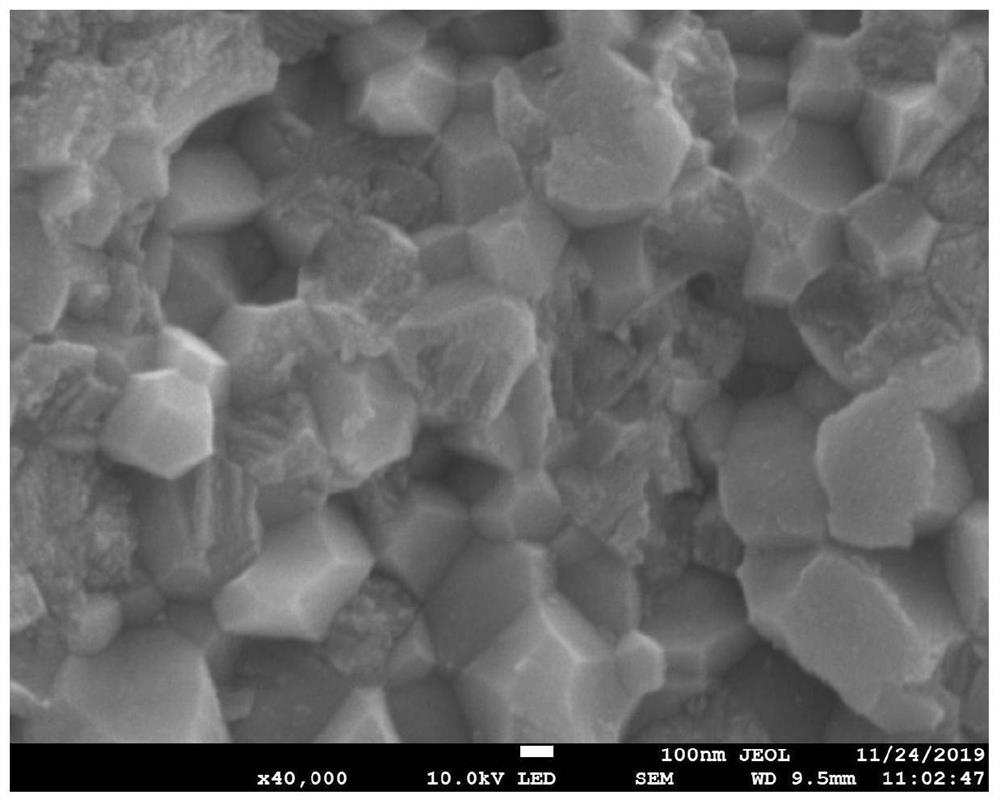

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of a zirconia ceramic material, comprising the following steps:

[0033] After mixing zirconia, metal oxide stabilizer, organic dispersant, polymer stabilizer and water, perform homogenization treatment to obtain a homogeneous mixed solution;

[0034] The homogeneous mixture is shaped to obtain a zirconia ceramic body;

[0035] The zirconia ceramic body is sequentially pre-sintered and final sintered to obtain the zirconia ceramic material;

[0036] The temperature of the pre-sintering is 600-1000°C;

[0037] The temperature of the final sintering is 1200-1400°C.

[0038] In the present invention, unless otherwise specified, the raw materials used are all commercially available products.

[0039] In the present invention, after mixing zirconia, oxide stabilizer, organic dispersant, polymer stabilizer and water, homogenization treatment is performed to obtain a homogeneous mixed solution.

[0040] In the present invention, ...

Embodiment 1

[0064] 1.76g of ammonium citrate, 14.5g of acrylamide and 0.5g of polyacrylamide were added to 106g of deionized water for first mixing to obtain a first mixed solution; 220g of zirconia and 12g of Y 2 O 3 Carry out the second mixing to obtain the mixed solid; carry out the third mixing of the first mixed solution and the mixed solid to obtain the second mixed solution; carry out the homogenization treatment of the second mixed solution in a planetary ball mill, and the ball milling speed is 200r / min, the time is 30min to obtain a homogeneous mixed solution;

[0065] The homogeneous mixed solution is obtained by grouting to obtain a wet blank, demoulded, and naturally air-dried to obtain a green blank;

[0066] Cutting the green body to obtain a zirconia ceramic body;

[0067] The zirconia ceramic body was calcined at 1000°C under normal pressure for 120h to obtain a pre-sintered body;

[0068] The pre-sintered green body is calcined at 1400 ℃ for 2 hours under normal pres...

Embodiment 2

[0073] Add 0.62g of ammonium polyacrylate and 2.2g of sodium alginate to 106g of deionized water, and perform first mixing to obtain a first mixed solution; 220g of zirconia and 12g of Y 2 O 3 Carry out the second mixing to obtain the mixed solid; carry out the third mixing of the first mixed solution and the mixed solid to obtain the second mixed solution; carry out the homogenization treatment of the second mixed solution in a planetary ball mill, and the ball milling speed is 200r / min, the time is 30min to obtain a homogeneous mixed solution;

[0074] The homogeneous mixed solution is formed by grouting to obtain a wet blank, the wet blank has a certain mechanical strength and then demoulded, and naturally air-dried to obtain a green blank;

[0075] Cutting the green body to obtain a zirconia ceramic body;

[0076] The zirconia ceramic body was calcined at 1000°C under normal pressure for 120h to obtain a pre-sintered body;

[0077] The pre-sintered green body is calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com