Method for preparing high-voltage gradient zinc oxide piezo-resistance by doping and coating method

A varistor and zinc oxide technology, which is applied in the direction of varistors and varistor cores, can solve the problems of increased production costs, difficulty in uniformity, and difficulty in achieving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

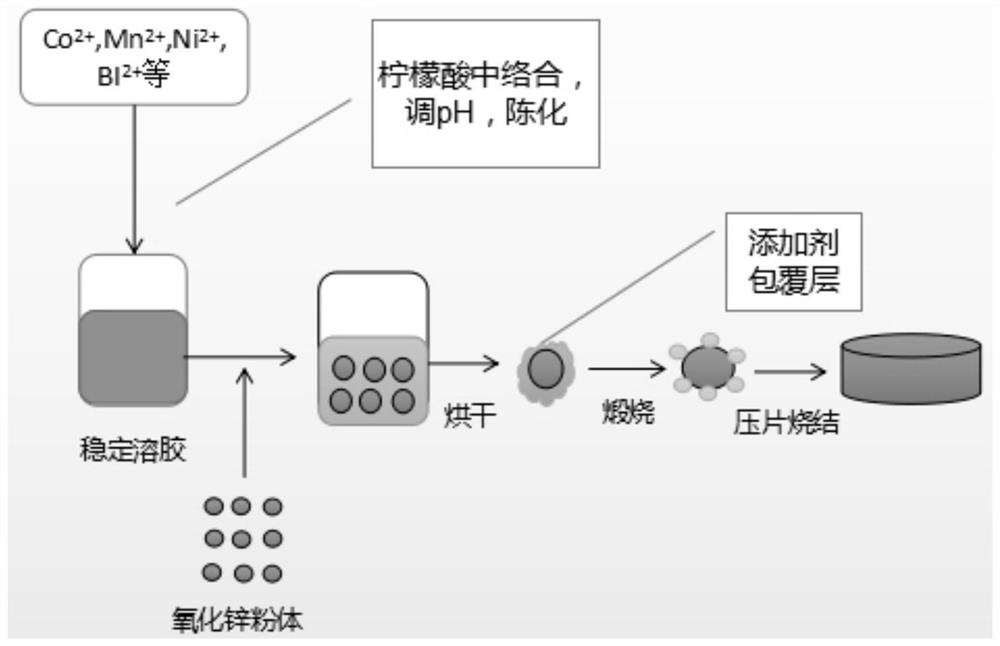

[0031] A method for preparing a high-voltage gradient zinc oxide varistor by a doping coating method, characterized in that it includes the following steps:

[0032] Step S1: Dissolve manganese carbonate, bismuth oxide, nickel hydroxide, and cobalt nitrate hexahydrate in excess nitric acid respectively, and prepare nitric acid with 25% dilute nitric acid in a volumetric flask to obtain 0.05mol / L nitric acid Manganese nitrate of cobalt, 0.06mol / L, bismuth nitrate of 0.1mol / L, nickel nitrate of 0.09mol / L, and the prepared salt solution is measured in proportion and uniformly mixed to obtain a sol, and the tin dichloride solution is dissolved in ethanol.

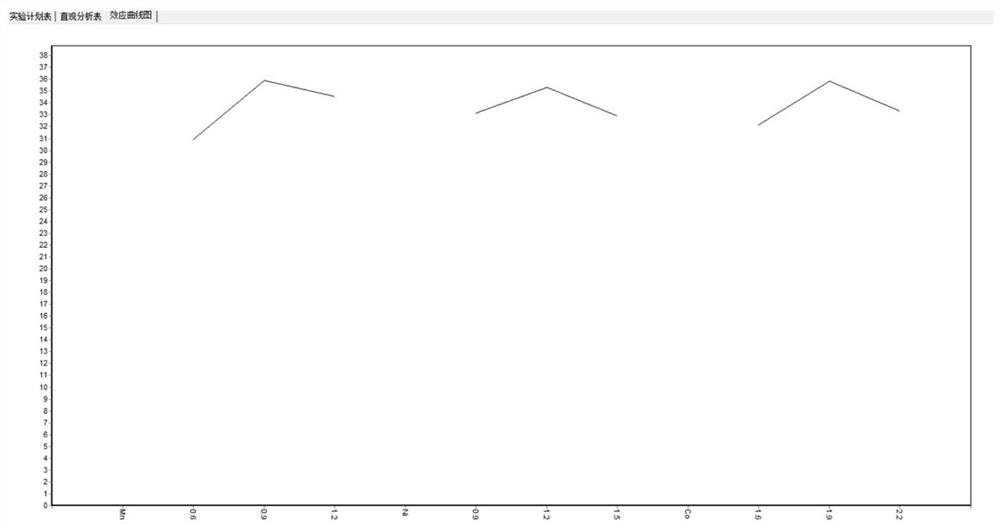

[0033] Step S2: drop the sol prepared in step S1 and tin dichloride dissolved in ethanol into the citric acid solution respectively, adjust the pH to 6.0, and prepare a wet sol in a water bath for 5 hours.

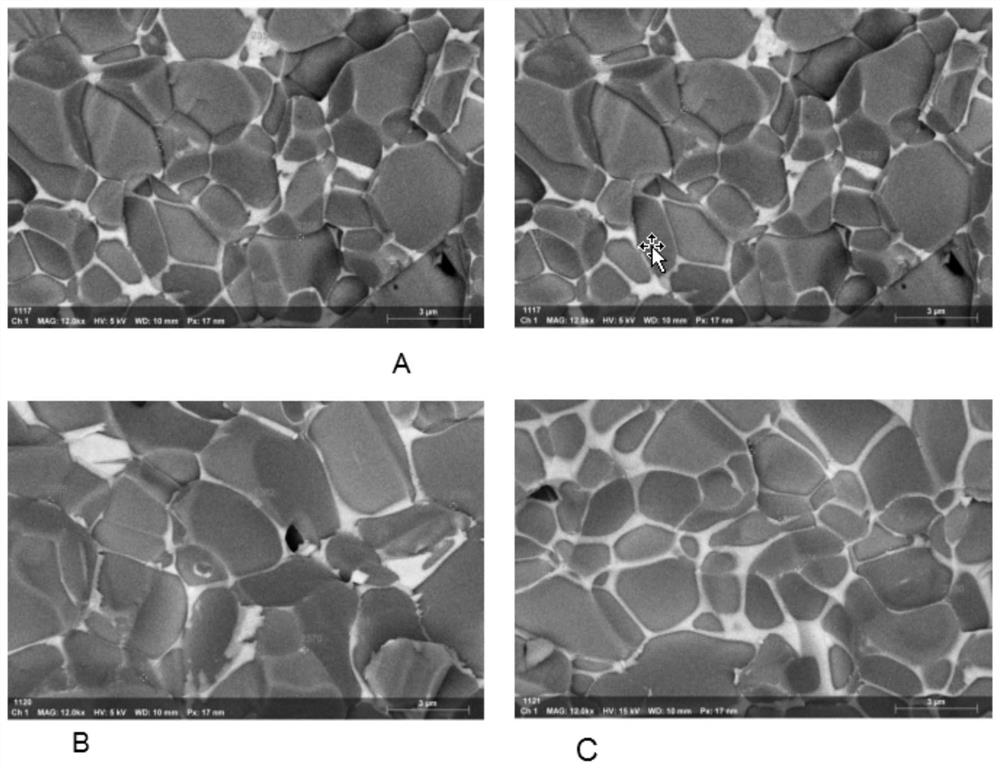

[0034] Step S3: adding ZnO to the wet sol prepared in step S2 to form a coated gel, adding a stirrer to continuously sti...

Embodiment 2

[0045] A method for preparing a high-voltage gradient zinc oxide varistor by a doping coating method, characterized in that it includes the following steps:

[0046] Step S1: Dissolve manganese carbonate, bismuth oxide, nickel hydroxide, and cobalt nitrate hexahydrate in excess nitric acid respectively, and prepare nitric acid with 25% dilute nitric acid in a volumetric flask to obtain 0.05mol / L nitric acid Manganese nitrate of cobalt, 0.06mol / L, bismuth nitrate of 0.1mol / L, nickel nitrate of 0.09mol / L, and the prepared salt solution is measured in proportion and uniformly mixed to obtain a sol, and the tin dichloride solution is dissolved in ethanol.

[0047]Step S2: drop the sol prepared in step S1 and tin dichloride dissolved in ethanol into the citric acid solution respectively, adjust the pH to 5.0, and prepare a wet sol in a water bath for 5 hours.

[0048] Step S3: adding ZnO to the wet sol prepared in step S2 to form a coated gel, adding a stirrer to continue the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com