Co2Z type ferrite material and preparation method thereof

A ferrite material and material technology, applied in the field of Co2Z type ferrite material and its preparation, can solve the problems of low resonance frequency of Z ferrite and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

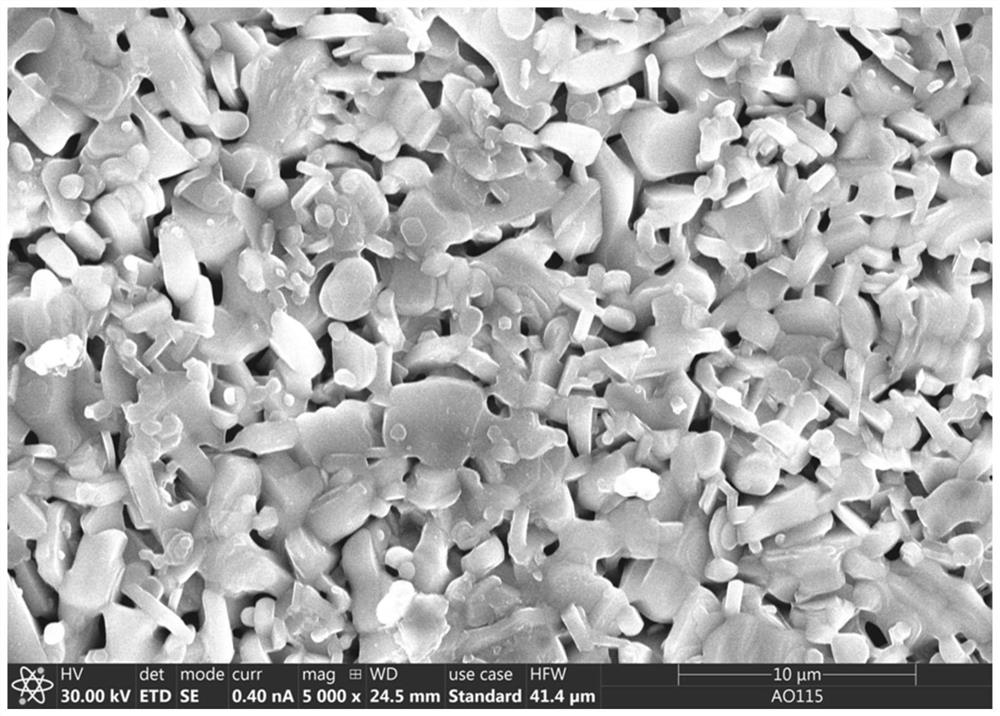

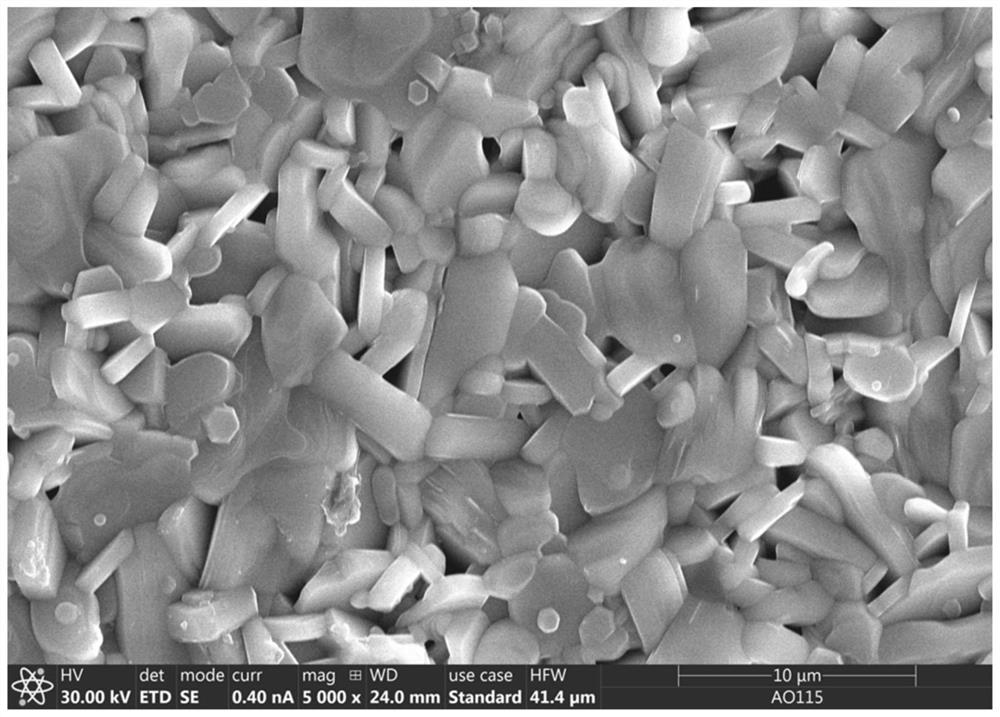

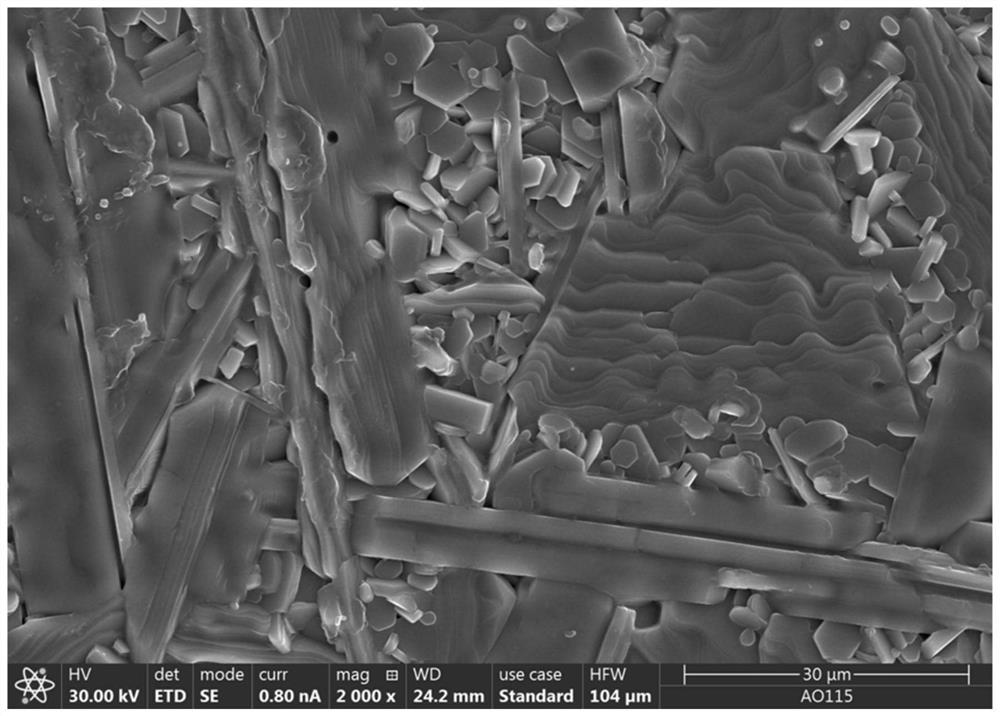

Image

Examples

Embodiment 1

[0041] In this case Co 2 The preparation method of the Z-type ferrite material is as follows:

[0042] Raw material BaCO 3 , SrCO 3 , Fe 2 o 3 、Co 3 o 4 According to Ba 1.5 Sr 1.5 co 2 Fe 21.6 o 41 The ratio is matched. The raw materials are first dried in an oven for 10 hours (the drying temperature is 120°C), and the proportions are made according to the above ingredients, and then put into a ball mill tank for ball milling. The balls are steel balls (the ratio of material to ball is 1:10, and the ball milling medium It is water, and the ratio of raw materials is 1:1).

[0043] Put the ball-milled powder into an oven for drying (drying temperature is 120°C). After drying, put the powder into an alumina crucible and put it into a high-temperature furnace for sintering. The heating rate is 5°C / min. The sintering temperature is 1280°C, and the sintering time is 2 hours.

[0044] The sintered powder is ground and passed through a 100-mesh sieve, and the sieved powd...

Embodiment 2

[0047] In this case Co 2 The preparation method of the Z-type ferrite material is as follows:

[0048] Raw material BaCO 3 , SrCO 3 , Fe 2 o 3 、Co 3 o 4 According to Ba 1.5 Sr 1.5 co 2 Fe 21.6 o 41 The ratio is matched. The raw materials are first dried in an oven for 10 hours (the drying temperature is 120°C), and the proportions are made according to the above ingredients, and then put into a ball mill tank for ball milling. The balls are steel balls (the ratio of material to ball is 1:10, and the ball milling medium It is water, and the ratio of raw materials is 1:1).

[0049] Put the ball-milled powder into an oven for drying (drying temperature is 120°C). After drying, put the powder into an alumina crucible and put it into a high-temperature furnace for sintering. The heating rate is 5°C / min. The sintering temperature is 1280°C, and the sintering time is 2 hours.

[0050] The sintered powder is ground and passed through a 100-mesh sieve, and the sieved powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com