High saturation magnetization z-type hexagonal ferrite powder and preparation method thereof

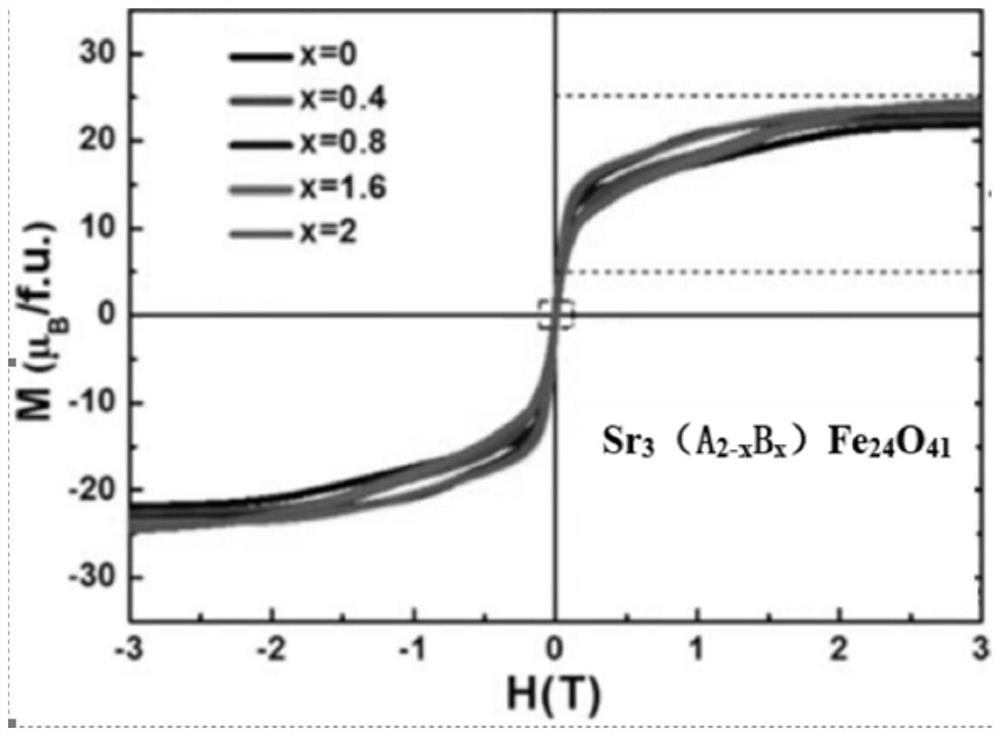

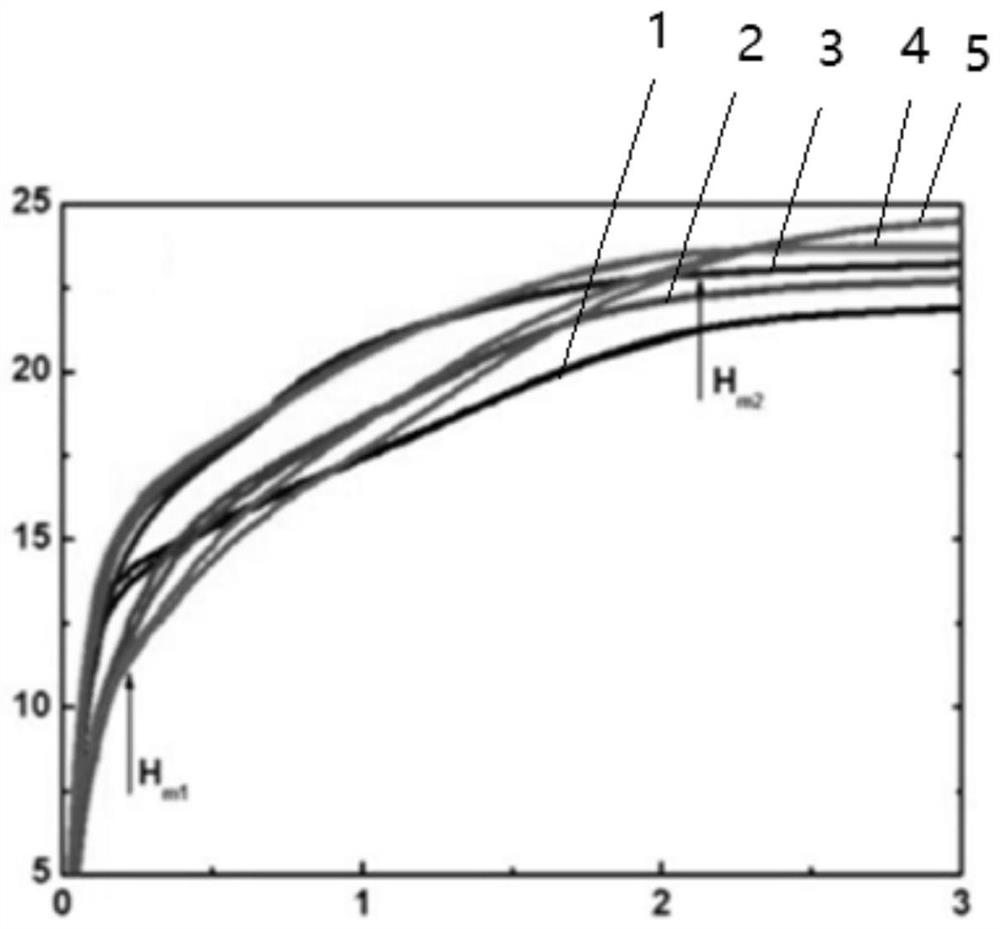

A technology of hexagonal ferrite and magnetization, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of insufficient saturation magnetization and limited performance of hexagonal ferrite, and achieve the purpose of changing the exchange effect , the effect of increasing the saturation magnetization and high local average magnetic moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

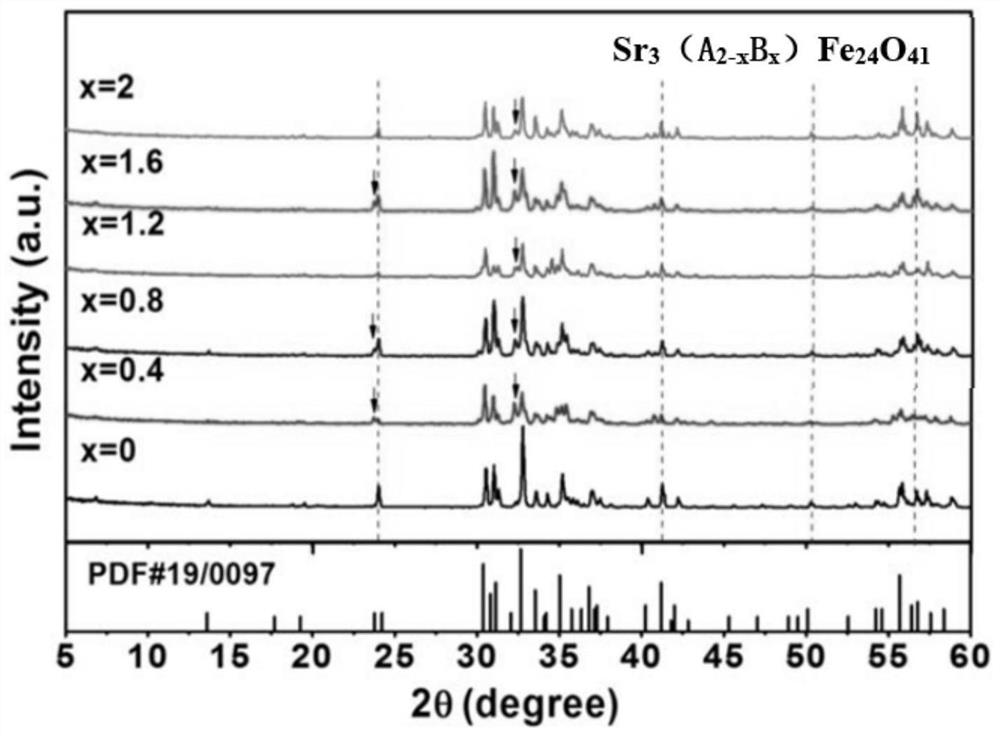

[0025] A high saturation magnetization Z-type hexagonal ferrite powder, the structure of the high saturation magnetization Z-type hexagonal ferrite powder is Sr 3 Co 2 Fe 24 O 41 .

[0026] A preparation method of high saturation magnetization Z-type hexagonal ferrite powder, wherein, comprising the following steps:

[0027] (1) With high purity SrCO 3 , Co 2 O 3 , Fe 2 O 3 The powder is the raw material, and each raw material is weighed according to the atomic molar ratio in the molecular formula;

[0028] (2) Mix the weighed raw materials and place them in a ball mill, add alcohol and ball milling beads to the ball mill, then place the ball mill on a ball mill for ball milling, and obtain a mixed solution after ball milling. min, the ball milling time is 10 hours;

[0029] (3) The mixed solution after ball milling is placed in a mortar, and the mortar is dried in a dryer to obtain the first powder. The drying temperature is controlled to be 90°C, and the drying tim...

Embodiment 2

[0034] A high saturation magnetization Z-type hexagonal ferrite powder, the structure of the high saturation magnetization Z-type hexagonal ferrite powder is Sr 3 Co 1.6 Zn 0.4 Fe 24 O 41 .

[0035] A preparation method of high saturation magnetization Z-type hexagonal ferrite powder, wherein, comprising the following steps:

[0036] (1) With high purity SrCO 3 , Co 2 O 3 , ZnO, Fe 2 O 3 The powder is the raw material, and each raw material is weighed according to the atomic molar ratio in the molecular formula;

[0037] (2) Mix the weighed raw materials and place them in a ball mill, add alcohol and ball milling beads to the ball mill, then place the ball mill on a ball mill for ball milling, and obtain a mixed solution after ball milling. min, the ball milling time is 10h;

[0038] (3) The mixed solution after ball milling is placed in a mortar, and the mortar is dried in a dryer to obtain the first powder. The drying temperature is controlled to be 90°C, and the ...

Embodiment 3

[0043] A high saturation magnetization Z-type hexagonal ferrite powder, the structure of the high saturation magnetization Z-type hexagonal ferrite powder is Sr 3 Co 1.2 Zn 0.8 Fe24 O 41 .

[0044] A preparation method of high saturation magnetization Z-type hexagonal ferrite powder, wherein, comprising the following steps:

[0045] (1) With high purity SrCO 3 , Co 2 O 3 , ZnO, Fe 2 O 3 The powder is the raw material, and each raw material is weighed according to the atomic molar ratio in the molecular formula;

[0046] (2) Mix the weighed raw materials and place them in a ball mill, add alcohol and ball milling beads to the ball mill, then place the ball mill on a ball mill for ball milling, and obtain a mixed solution after ball milling. min, the ball milling time is 10h;

[0047] (3) The mixed solution after ball milling is placed in a mortar, and the mortar is dried in a dryer to obtain the first powder. The drying temperature is controlled to be 90°C, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com