A kind of multi-layer electromagnetic shielding composite material based on isolation structure and its preparation method and application

A technology of electromagnetic shielding and composite materials, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, lamination, etc., can solve problems such as the mismatch between composite materials and air impedance, the reduction of mechanical properties of composite materials, and the inability to meet practical applications. Achieve the effects of improving shielding efficiency, high electromagnetic shielding effectiveness, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

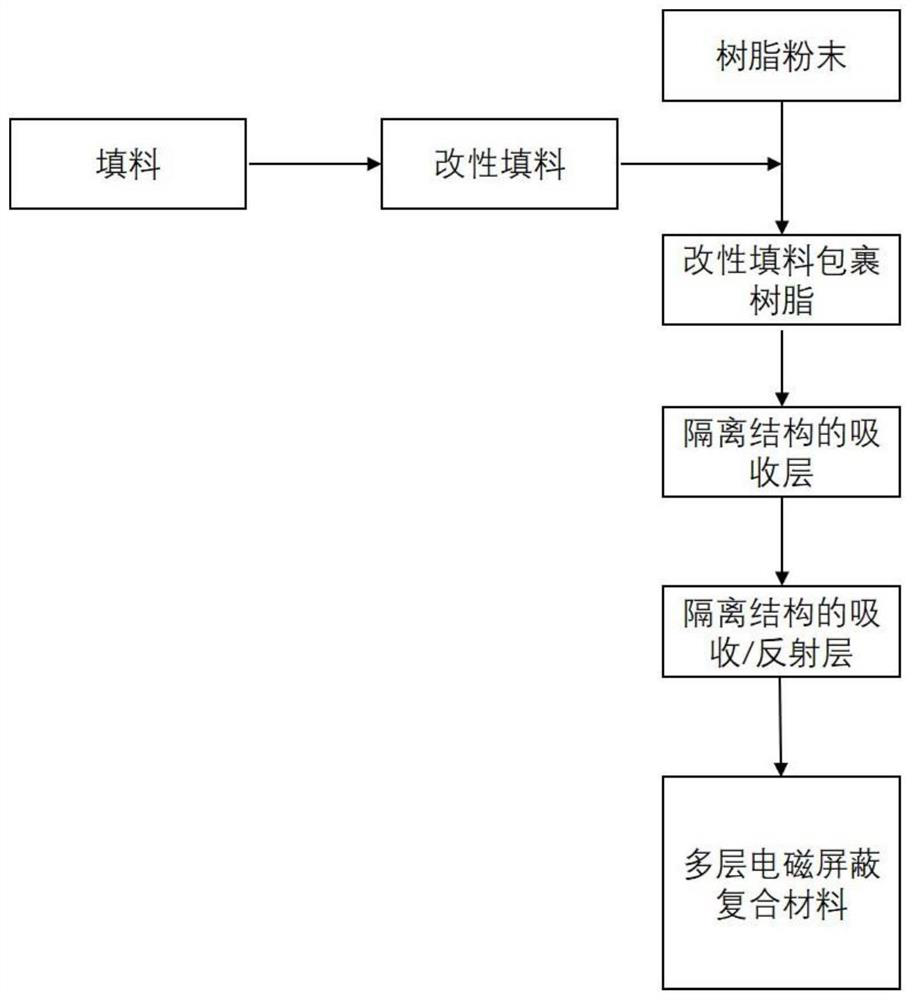

[0087] The invention provides a preparation method of electromagnetic shielding composite material, comprising the following steps:

[0088] 1) Mixing filler A and solvent, then adding filler B to continue mixing, then adding ferric chloride, alkali and hydrazine hydrate and mixing again, and reacting to obtain a modified filler;

[0089] 2) After stirring and mixing the modified filler and resin obtained in the above steps, hot pressing is performed to obtain a modified resin layer with an isolation structure;

[0090] 3) Compounding the plasma-treated metal nanowire dispersion on the modified resin layer with an isolation structure to obtain an electromagnetic shielding composite material.

[0091] The selection and composition of the raw materials required in the above-mentioned preparation process, as well as the corresponding optimization principles, in the present invention can correspond to the selection and composition of the corresponding raw materials in the electrom...

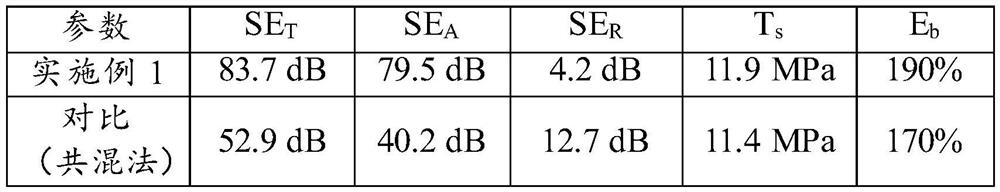

Embodiment 1

[0139] 1) Preparation of modified filler:

[0140] First, 1 g of graphene nanosheets were added to methanol for ultrasonic dispersion for 3 hours, then 1 g of graphene oxide was added, and the ultrasonic wave was continued for 3 hours. After stirring for 4 h, the above mixture was transferred to an autoclave and treated at 200 °C for 16 h. Finally, filter and wash after cooling to room temperature, and dry at 120°C to obtain the final modified filler.

[0141] 2) Preparation of absorbing layer:

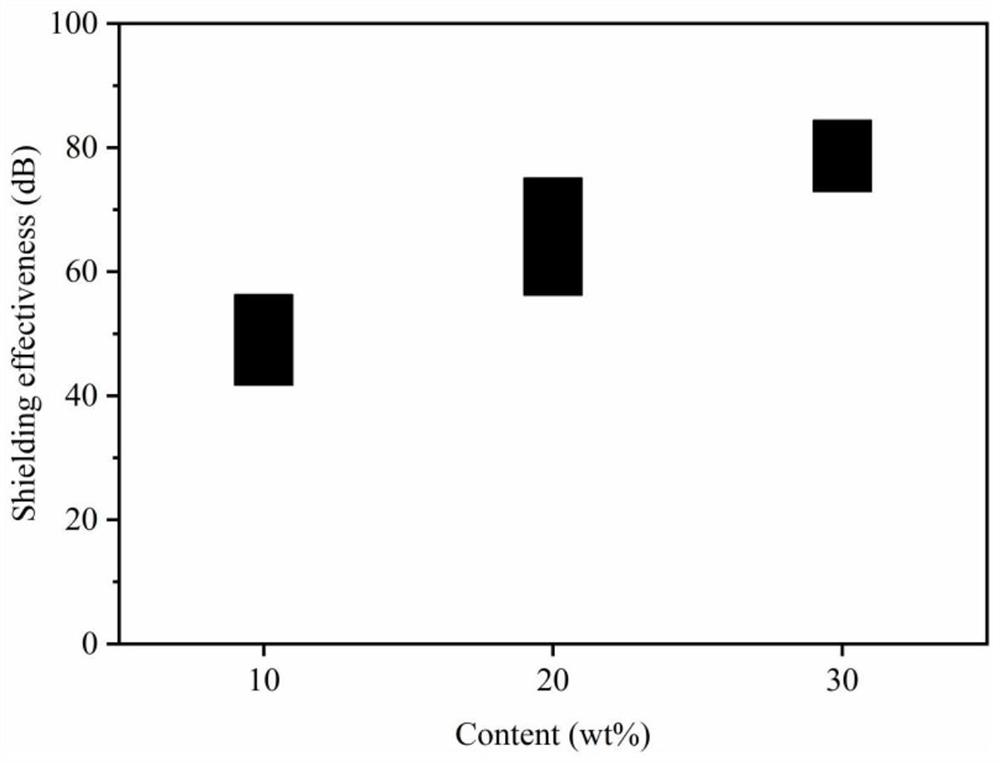

[0142] Weigh 7g of polyethylene resin and 3g of modified filler and mix in a mixer, and then hot-press at a temperature of 140°C and a pressure of 1MPa to obtain a 200um film, that is, the absorption layer.

[0143] 3) Preparation of absorption / reflection layer:

[0144] The silver nanowires (length: 50um; diameter: 50nm) were dispersed in ethanol at a concentration of 10mg / ml, the obtained film was treated with plasma for 60s, and then the silver nanowire dispersion was sprayed on...

Embodiment 2

[0157] 1) Preparation of modified filler:

[0158] First, 1 g of flake graphite was added to ethanol for ultrasonic dispersion for 1 h, then 0.5 g of acidified carbon nanotubes were added, and the ultrasonic wave was continued for 1 h. 5 g of ferric chloride, 15 g of potassium hydroxide and 0.625 g of hydrazine hydrate were respectively added to the above dispersion and stirred For 2 h, the above mixture was transferred to an autoclave and treated at 160 °C for 8 h. Finally, filter and wash after cooling to room temperature, and dry at 80°C to obtain the final modified filler.

[0159] 2) Preparation of absorbing layer:

[0160] 9g of polypropylene was weighed and mixed with 1g of modified filler in a mixer, and then hot-pressed at a temperature of 170°C and a pressure of 0.5MPa to obtain a film with a thickness of 50um, that is, an absorption layer.

[0161] 3) Preparation of absorption / reflection layer:

[0162] Gold nanowires (length: 10um; diameter: 200nm) were disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com