Secondary grinding lotus root starch processing device

A processing equipment and secondary grinding technology, applied in grain processing, food science and other directions, can solve problems such as the inability to process multiple lotus roots at the same time, the inability to filter out lotus root starch slurry water, and the discontinuous processing efficiency, etc., to achieve automatic operation, The effect of good market revenue and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

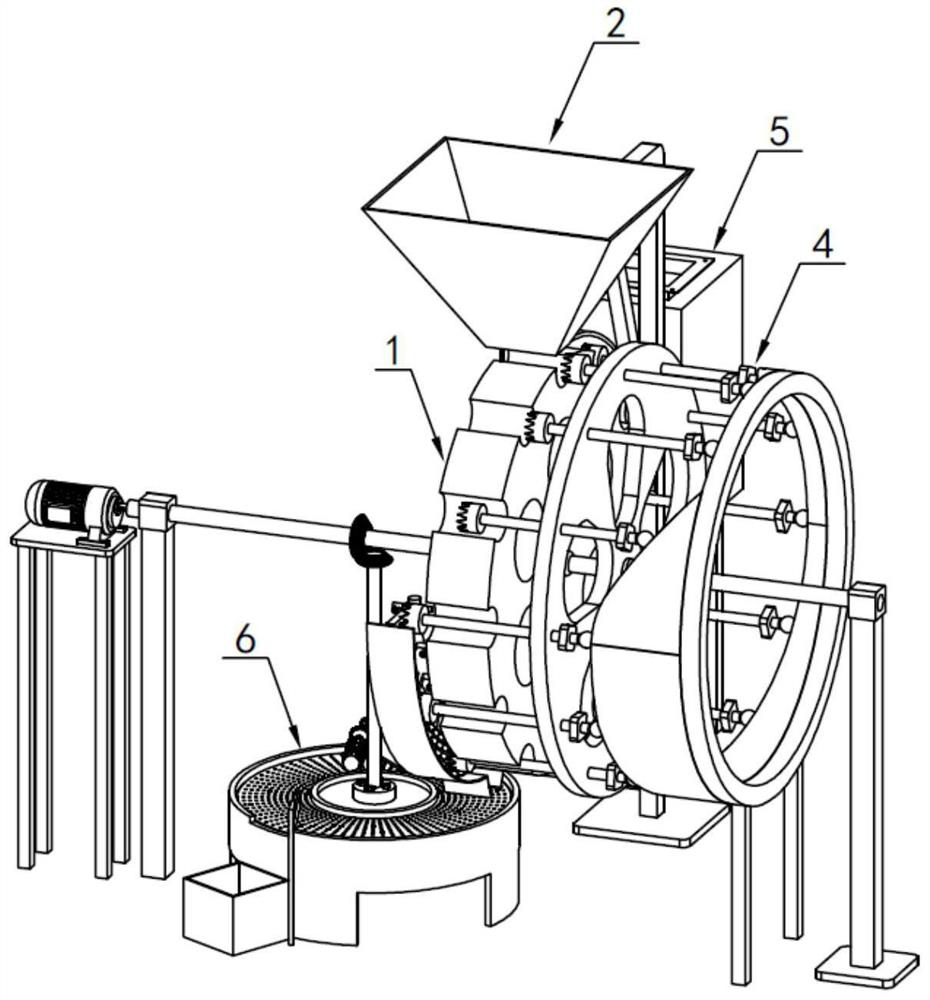

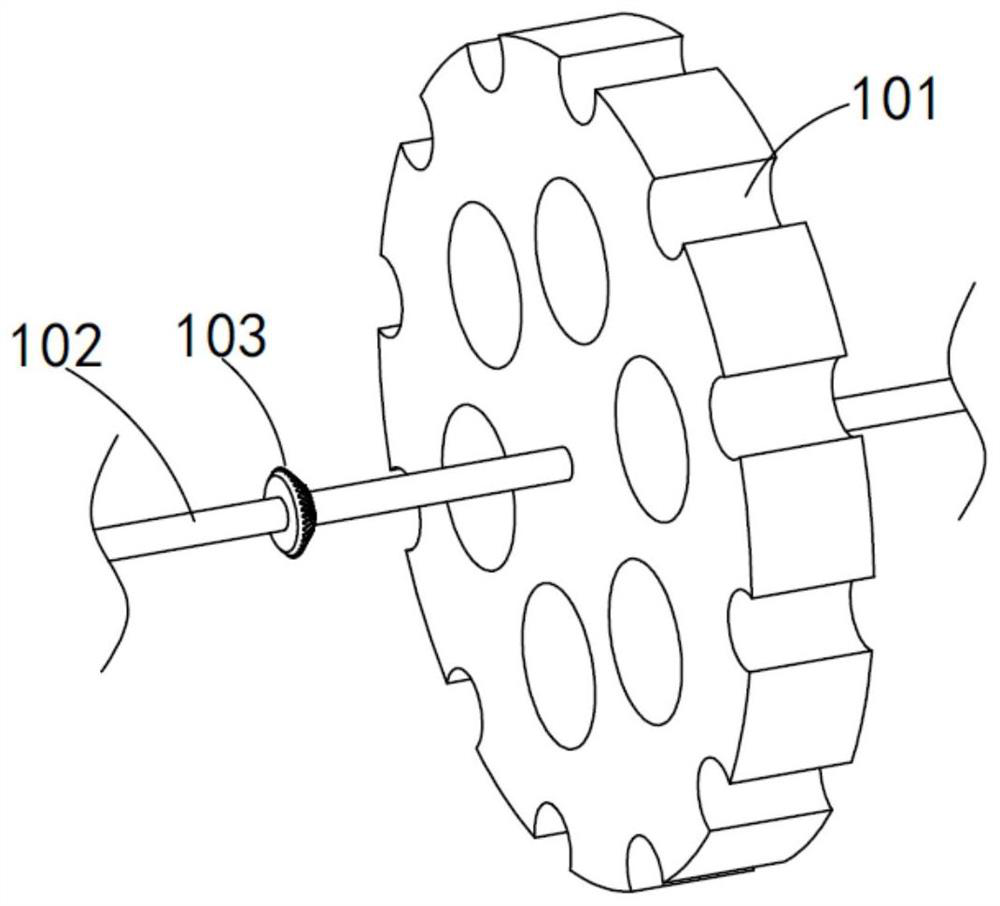

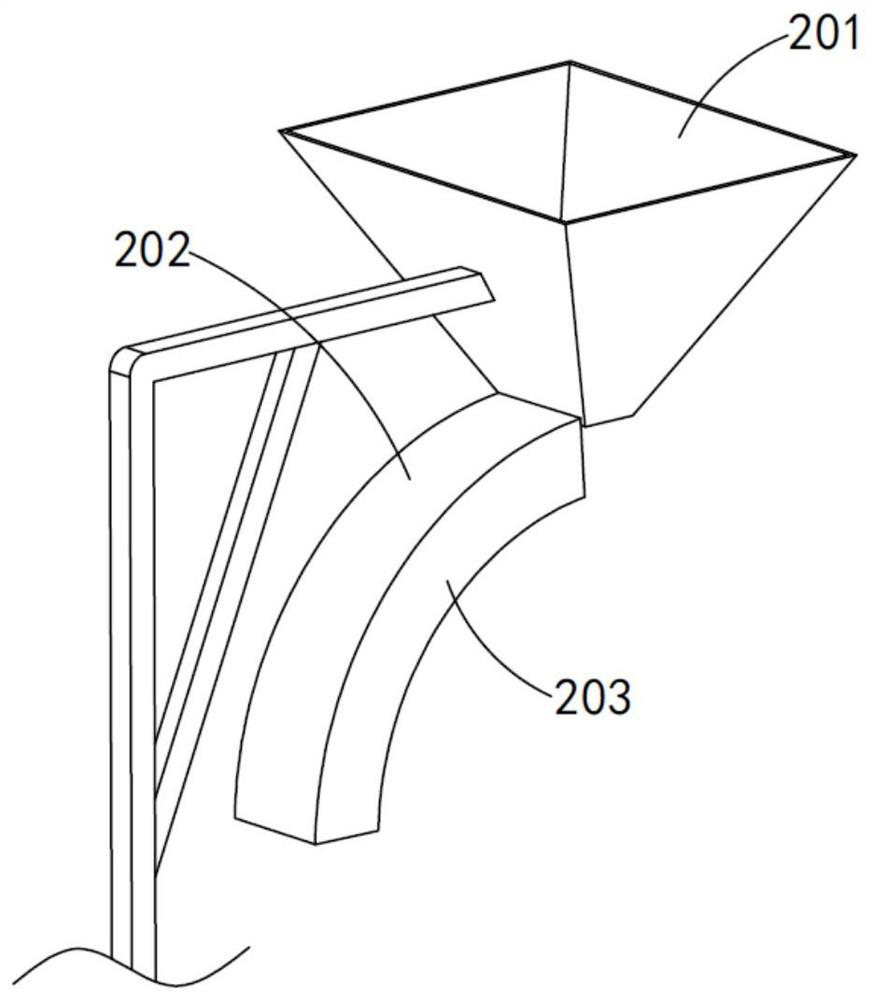

[0039] Such as Figure 1 to Figure 12 Shown, a kind of secondary grinding lotus root powder processing equipment comprises No. 1 turntable 1, and described No. 1 turntable 1 is provided with several arc bearing grooves 101 that are distributed in a circular array, and the top of described No. 1 turntable 1 is provided with corresponding With the feeding device 2, the arc-shaped bearing groove 101 is used to carry the single lotus root output by the feeding device 2 and make a circular motion under the drive of the No. 1 turntable 1. The two sides of the No. 1 turntable 1 are respectively equipped with The matching scraping device 3 and the pushing device 4, the pushing device 4 includes a pushing assembly 401 and a guiding assembly 402, and the pushing assembly 401 is used to push and support the No. 1 turntable under the action of the guiding assembly 402 1, and drive the lotus root to move in the direction of the scraping device 3, cooperate with the scraping device 3 to per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com