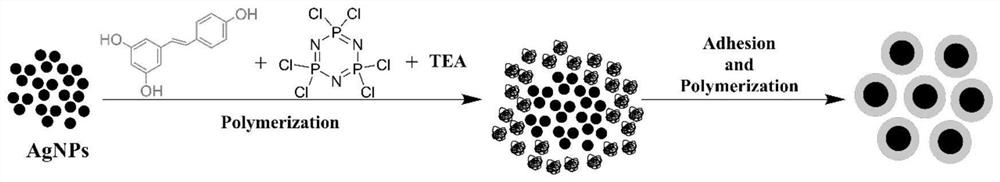

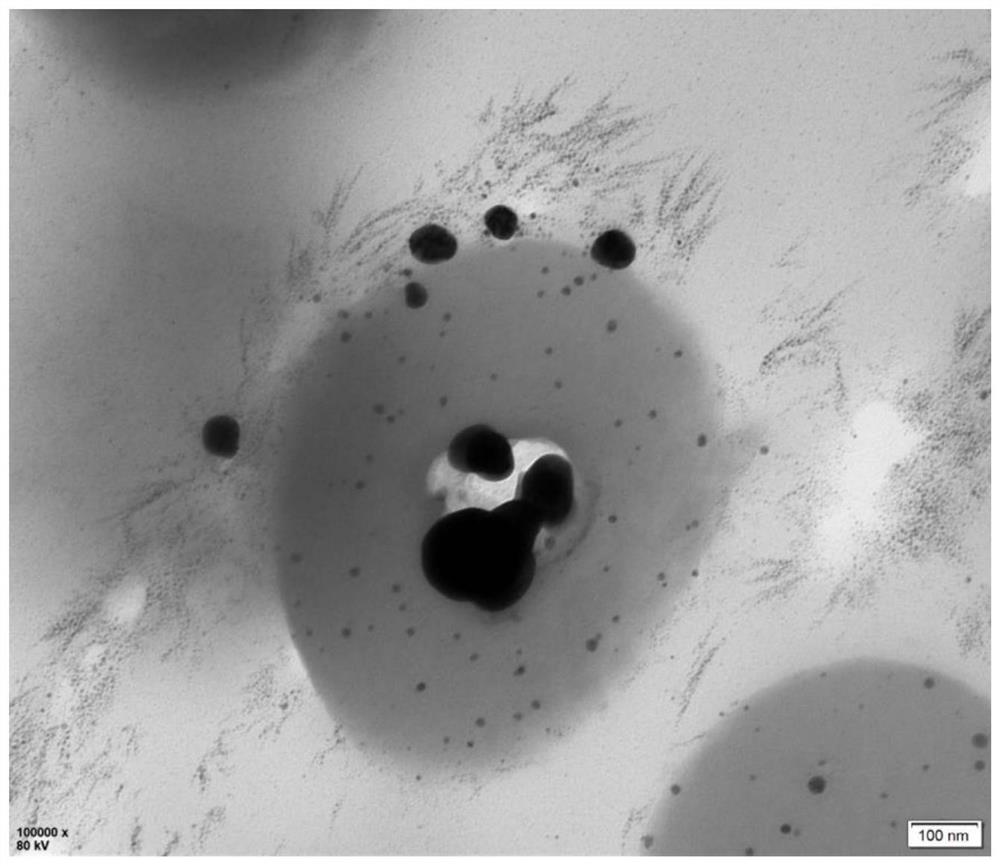

Silver-loaded polyphosphazene microsphere with mesoporous core-shell structure as well as preparation method and application of silver-loaded polyphosphazene microsphere

A technology of core-shell structure and polyphosphazene, which is applied in the field of mesoporous core-shell structure polyphosphazene silver-loaded microspheres and its preparation, can solve problems such as agglomeration, prone to oxidative discoloration, and loss of nano-characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Configure 100mL 0.1M silver nitrate solution in a 250ml flask as a silver source, add the same mole of polyvinylpyrrolidone K30 and Tween 60 of three thousandths of the solution weight in turn, and stir vigorously for 0.5h under dark conditions until all raw materials All dissolved to form a homogeneous transparent solution; after heating to 30°C, add 5 mL of 0.1M sodium borohydride solution dropwise, after the addition is complete, stir in the dark for 30 minutes until the reaction is complete, and centrifuge the product at 6000r / min Separation, repeated alternate washing with ethanol and deionized water for 3 times, vacuum drying at 60°C for 24 hours to obtain hard template single-phase nano-silver particles;

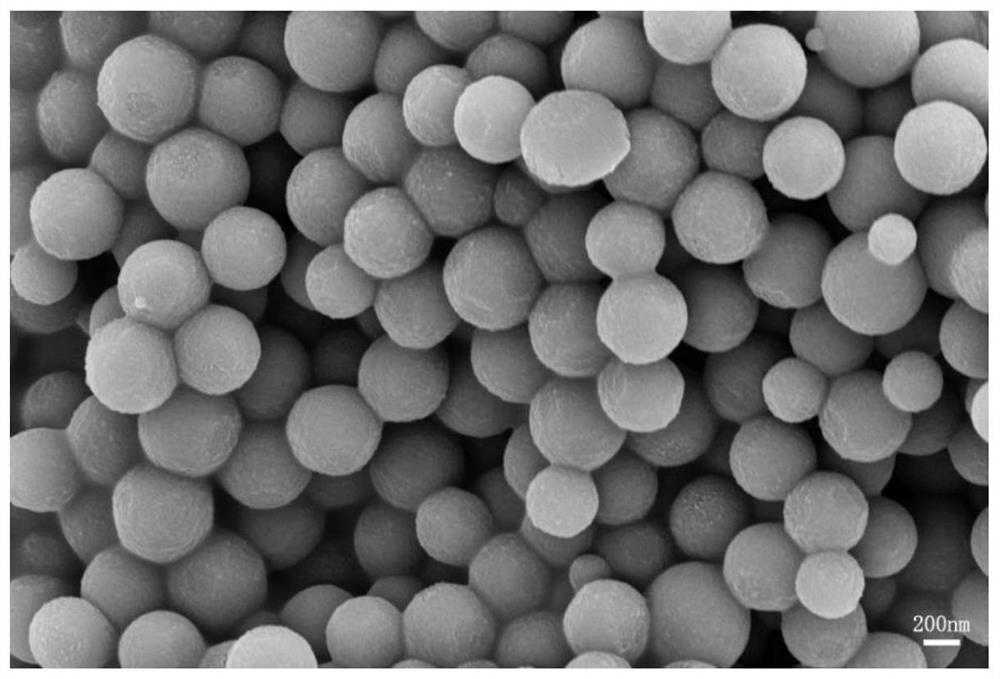

[0042] (2) Take 0.04g of single-phase nano-silver particles and re-disperse them ultrasonically in 500mL of acetonitrile with an ultrasonic power of 300 watts and an ultrasonic frequency of 50 kHz, and add Tween 80 at 3 / 1000 of the solution weight to form a ...

Embodiment 2

[0051] (1) Configure 100mL 0.15M silver nitrate solution in a 250ml flask as a silver source, add the same mole of polyvinylpyrrolidone K30 and Tween 80 with a solution weight of 5‰, and stir vigorously for 0.5h under dark conditions until all raw materials are completely dissolved to form a homogeneous transparent solution; after heating to 90°C, add 5 mL of 0.15M sodium borohydride solution dropwise, and after the addition is complete, stir the reaction for 30 minutes in the dark until the reaction is complete, and centrifuge the product at 10,000 r / min. And use ethanol and deionized water to repeatedly alternately wash 3 times, and vacuum dry for 24 hours to obtain hard template single-phase nano-silver particles.

[0052] (2) Take 0.04g of single-phase nano-silver particles and re-disperse them in 500mL of acetonitrile with ultrasonic power of 300W and ultrasonic frequency of 50kHz, and add Tween 80 with a solution weight of 5‰, and form a stable suspension liquid after 1h ...

Embodiment 3

[0055] (1) Configure 100mL 0.05M silver nitrate solution in a 250ml flask as a silver source, add the same mole of polyvinylpyrrolidone K90 and sodium dodecylbenzenesulfonate with a solution weight of 3.5‰ in sequence, and stir vigorously for 0.5h under dark conditions Until all the raw materials are completely dissolved to form a uniform transparent solution; after heating to 60°C, add 5mL of 0.05M sodium borohydride solution dropwise, and after the addition is complete, stir the reaction in the dark for 30min until the reaction is completed, and the product is heated at 8000r / min centrifuged at a rotating speed, washed three times alternately with ethanol and deionized water, and vacuum-dried for 24 hours to obtain hard template single-phase nano-silver particles.

[0056] (2) Take 0.04g of single-phase nano-silver particles and re-disperse them ultrasonically in 500mL of tetrahydrofuran with an ultrasonic power of 300 watts and an ultrasonic frequency of 50 kHz, and add Twee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mesoporous | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com