Hot rolled steel sheet

A technology of hot-rolled steel sheet and sheet width, which is applied in the field of hot-rolled steel sheet with high strength and excellent ductility and stretch flangeability, can solve the problems of damaged hole expandability, etc., and achieve the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

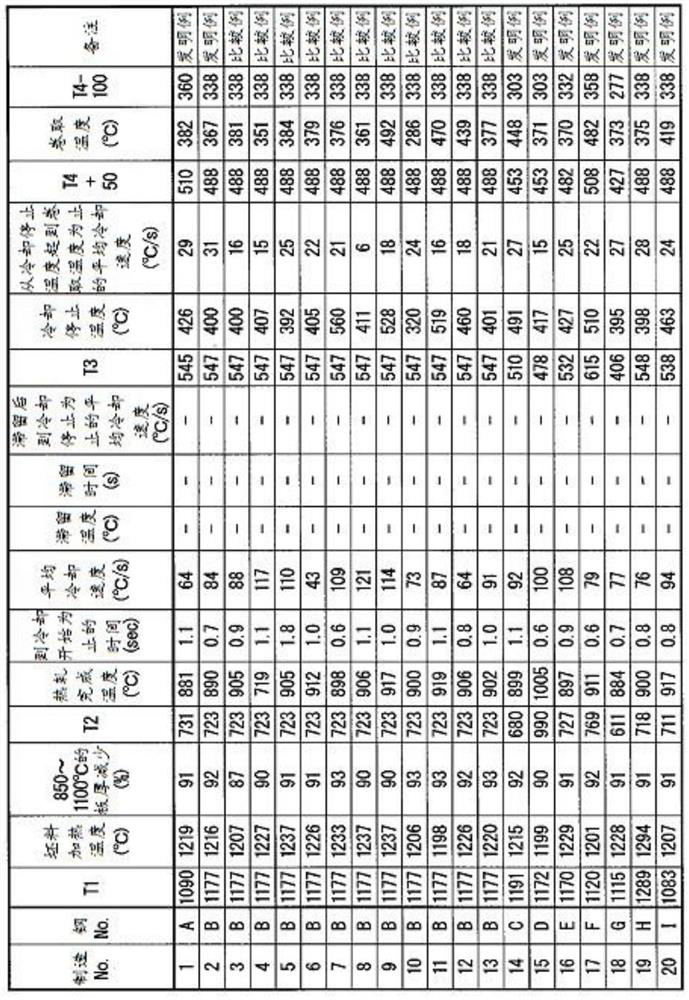

Examples

Embodiment Construction

[0078] Hereinafter, the chemical composition and metal structure of the hot-rolled steel sheet (hereinafter, sometimes abbreviated as steel sheet) according to the present embodiment will be specifically described. However, the present invention is not limited to the configuration disclosed in this embodiment, and various changes can be made without departing from the gist of the present invention.

[0079] In the numerical ranges described below, the lower limit and the upper limit are included in the range. For numerical values expressed as "less than" or "exceeded", the value is not included in the numerical range. In the following description, % related to the chemical composition of the steel sheet is mass % unless otherwise specified.

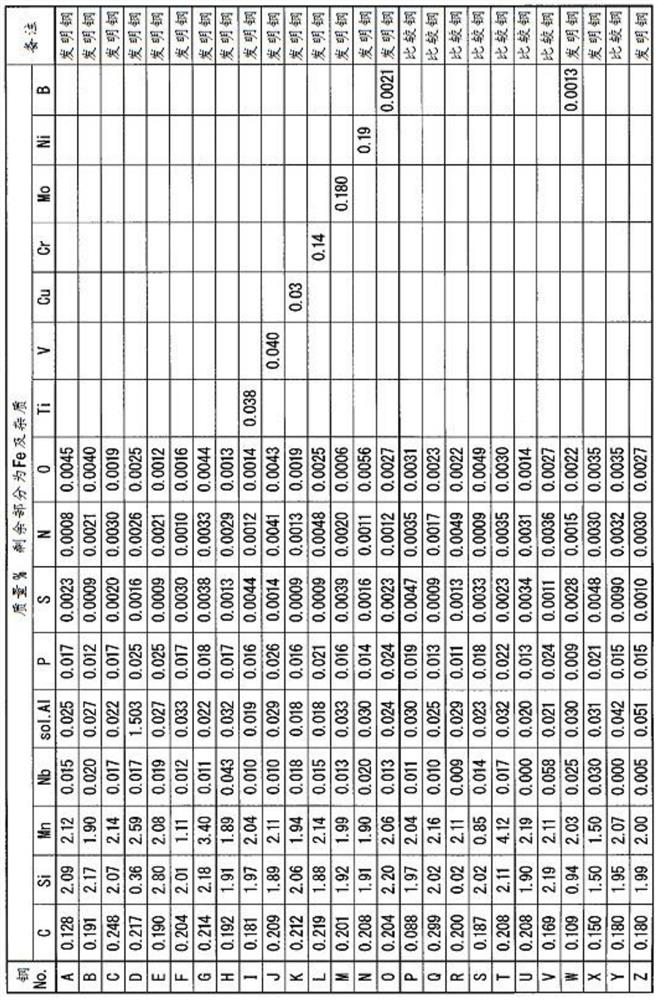

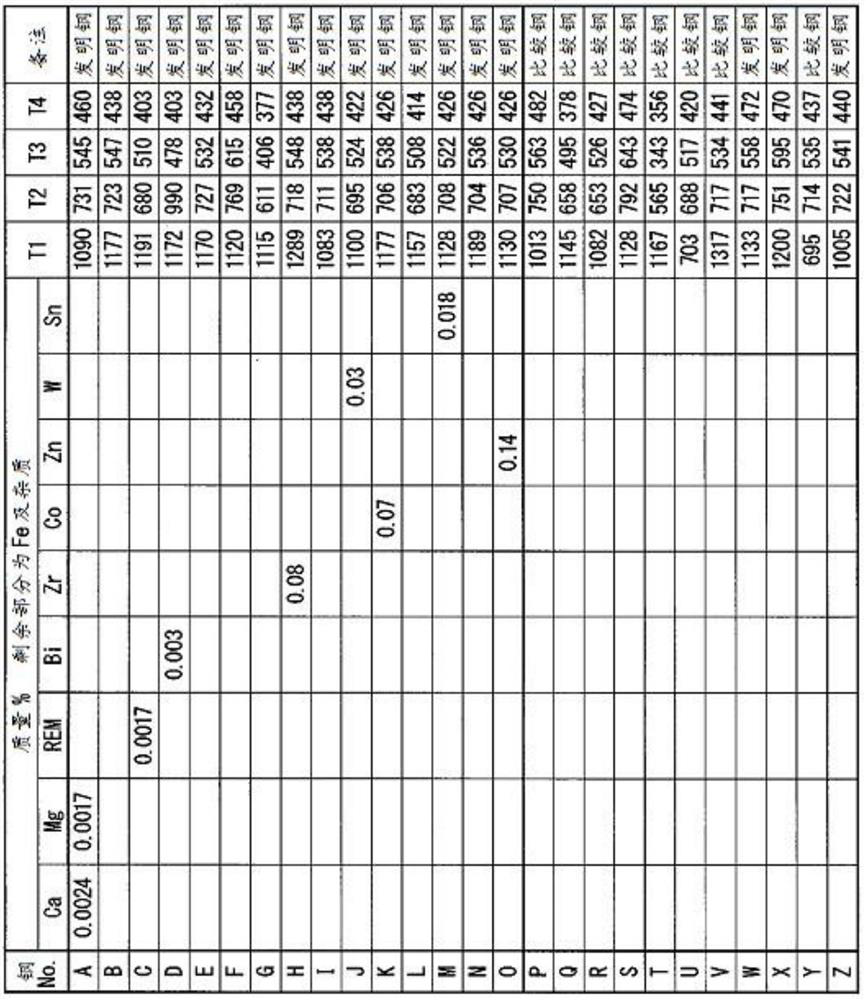

[0080] 1. Chemical composition

[0081] The hot-rolled steel sheet of the present embodiment contains C: 0.100-0.250%, Si: 0.05-3.00%, Mn: 1.00-4.00%, Nb: 0.005-0.050%, sol.Al: 0.001-2.000%, P: 0.100% or less, S: 0.0300% or less, N: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com