Cylindrical wire harness terminal and manufacturing method

A wire harness terminal and cylindrical technology, which is applied in the field of terminal blocks, can solve the problems of incapable of large-scale and long-term stable production, the fixing effect cannot meet the requirements, and the mold core wears quickly, so as to improve the service life, reduce loss, Effect of reducing punching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, under the condition of not conflicting with each other, the embodiments of the present application and the features in the embodiments can be combined with each other.

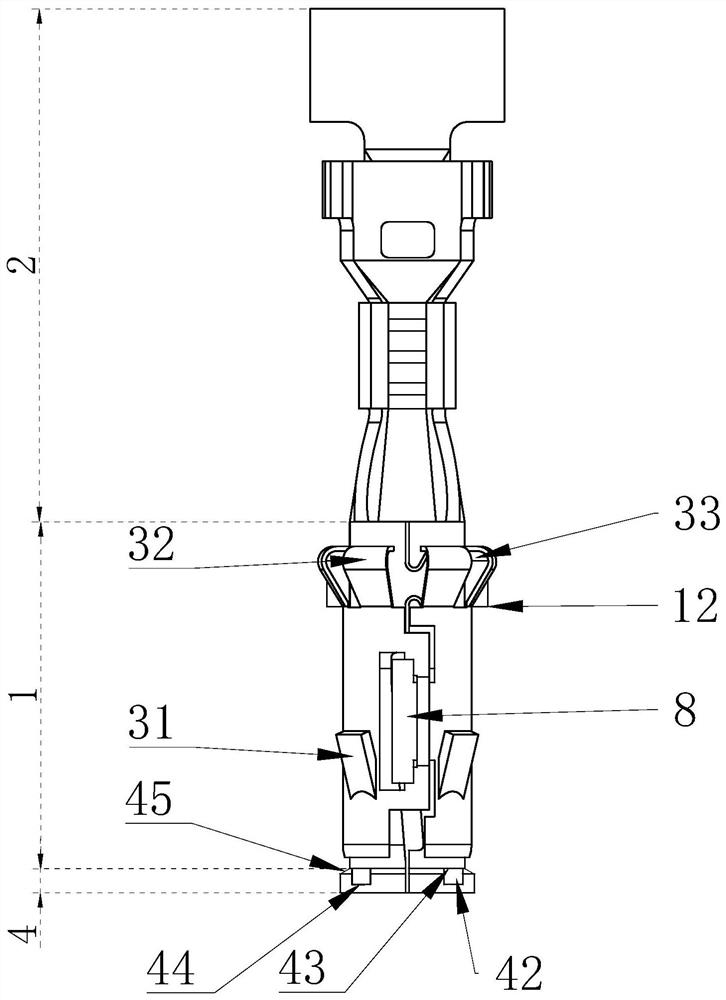

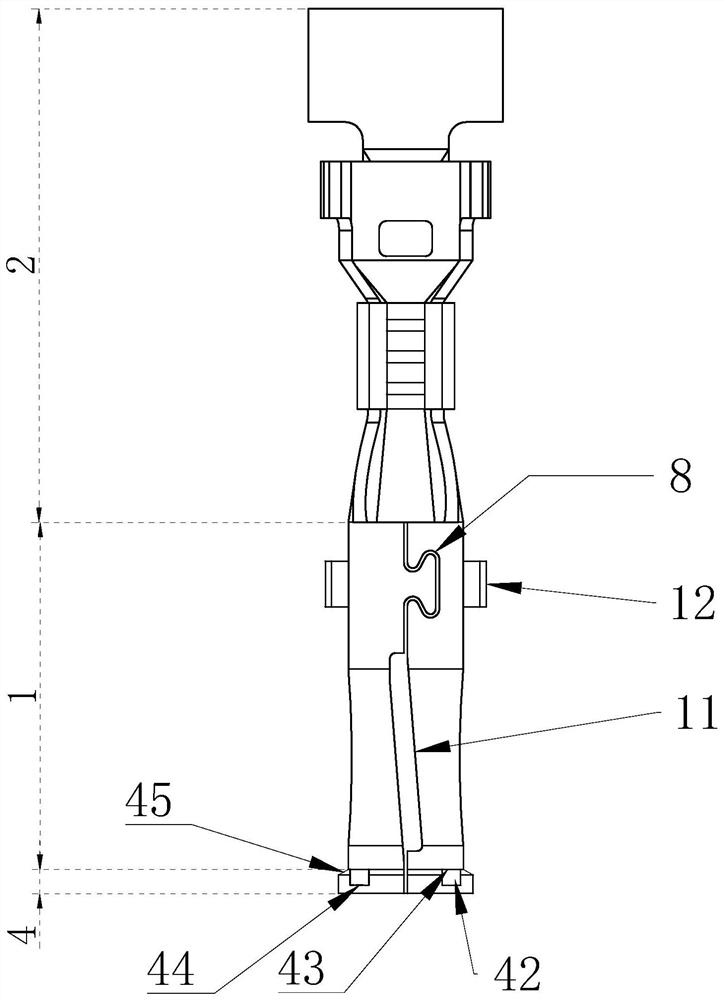

[0030] Such as Figure 1-3 As shown, it includes the mating area 1, the crimping area 2 and the blocking area 4 in sequence. The mating area 1, the crimping area 2 and the blocking area 4 are connected as a whole and are all made of alloy copper. The left and right sides of the mating area 1 are buckled together. Forming a cylindrical shape, the blocking area 4 forms a stepped side wall higher than the mating area 1 by stamping. U-shaped limiting piece 42, the upper end of the limiting piece 42 is a free end 43 and the end face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com