Annular side suction hood for crucible dust removal and dust collection method thereof

A ring-shaped cover and ring-shaped technology is applied in the field of crucible dust removal, which can solve the problems of poor dust suction effect, and achieve the effects of efficient dust collection, reliability and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A specific embodiment of the present invention discloses an annular side suction hood for dust removal from a crucible and a dust suction method thereof, which can be used to efficiently collect dust and waste gas generated during the melting, refining and degassing of aluminum alloys using a crucible resistance furnace.

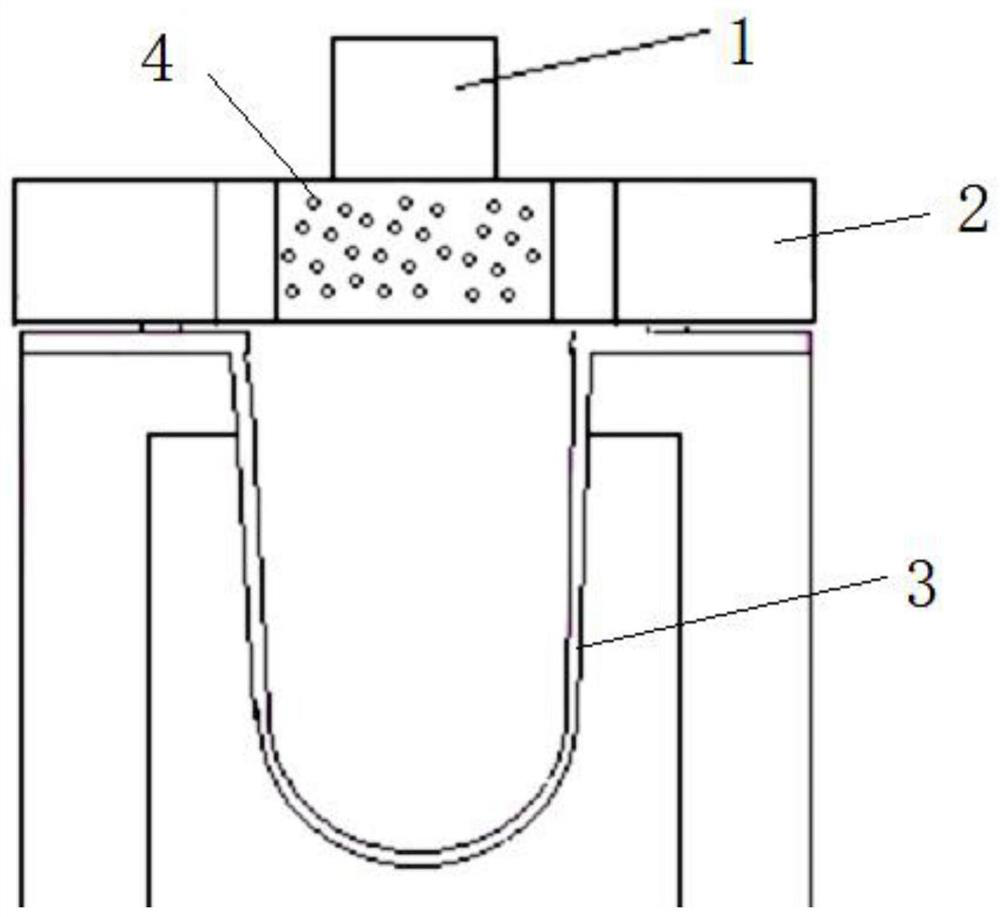

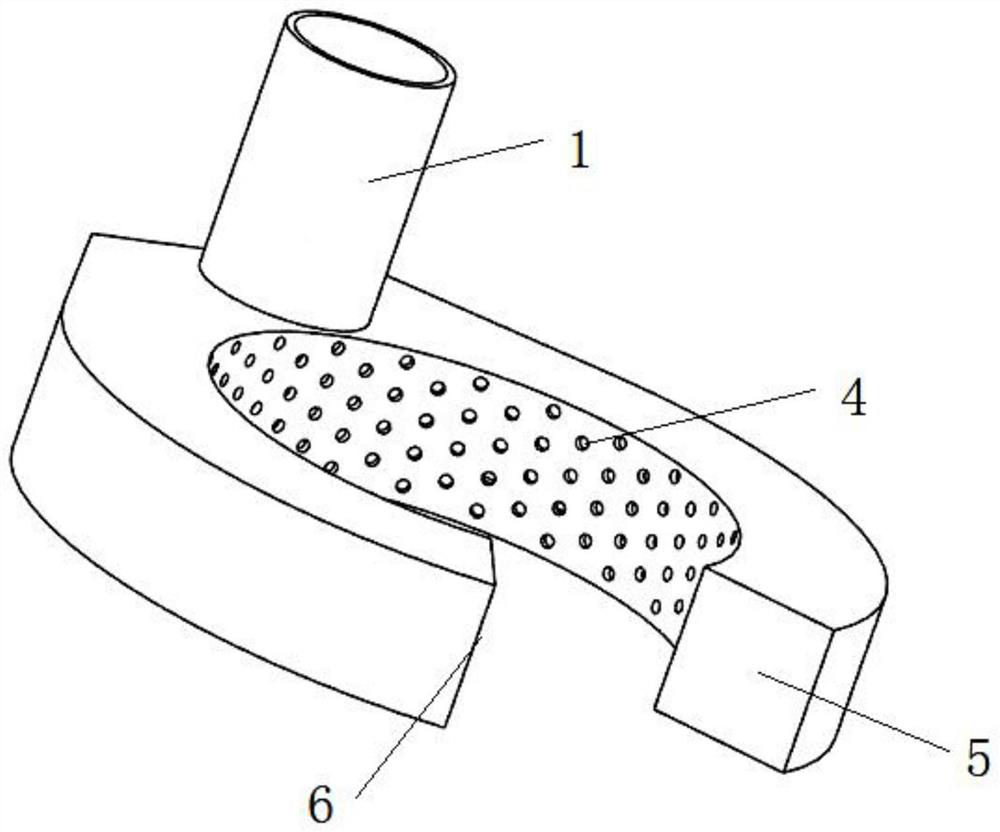

[0044] Specifically, such as figure 1 , figure 2 As shown, the annular side suction hood for dedusting the crucible includes: a suction tube 1 and an annular cover 2 , the suction tube 1 is arranged above the annular cover 2 , and the suction tube 1 communicates with the annular cover 2 . The suction cylinder 1 is connected with the dust remover, and the dust remover provides the suction pressure for suction and dust removal.

[0045] Further, the air suction cylinder 1 is cylindrical, and the air suction cylinder 1 is perpendicular to the annular cover 2 .

[0046] Further, the annular cover 2 is a circular cover structure with an inner cavity.

...

Embodiment 2

[0073] A specific embodiment of the present invention provides an annular side suction hood with a middle partition (not shown in the figure), the difference from Embodiment 1 is that the middle partition 8 is used for the partition.

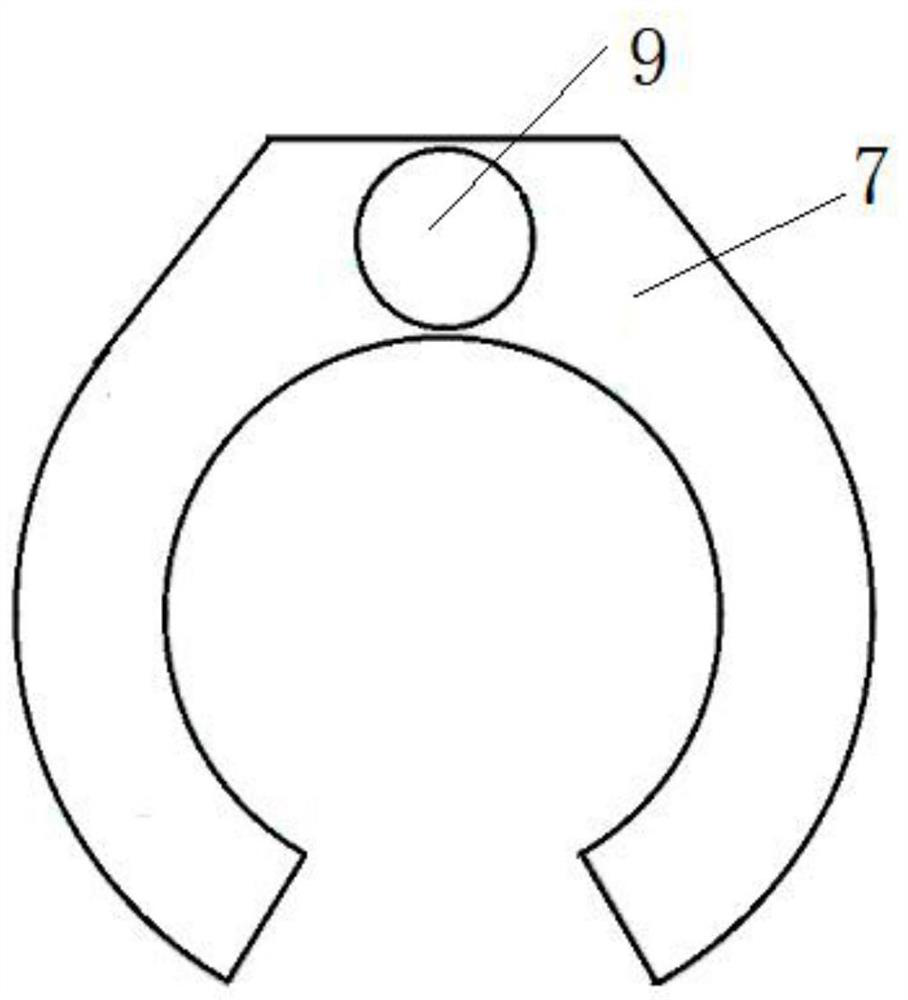

[0074] Such as Figure 4 As shown, the shape of the middle partition 8 is the same as that of the upper cover 7 , the middle partition 8 is arranged inside the annular cover 2 , and the middle partition 8 is arranged parallel to the upper cover 7 .

[0075] The middle partition 8 divides the inner cavity of the annular cover 2 into two cavities. Specifically, the middle partition 8 divides the inner cavity of the annular cover 2 into an upper dust suction chamber and a lower dust suction chamber.

[0076] Further, a plurality of second communication holes 10 are provided on the middle partition 8, and the second communication holes 10 are used for connecting the upper dust suction chamber and the lower dust suction chamber.

[0077] Preferably...

Embodiment 3

[0083] This embodiment provides a design method for the annular side suction hood of Embodiment 1 or Embodiment 2, specifically, including the following steps:

[0084] Step (1) Determine the suction wind speed of the annular side suction hood and the external dimensions of the annular side suction hood according to the size of the crucible furnace in combination with the concentration of dust or exhaust gas emissions in the production process;

[0085] Step (2) According to the suction wind speed of the annular side suction hood and the external dimensions of the annular side suction hood, design the size of the opening (dust suction hole 4) of the annular cover 2, the number of openings (dust suction hole 4) and the hole (suction hole 4). Dust hole 4) position distribution;

[0086] Step (3) according to the above parameters, for the air volume and the wind speed of each position of the uniform annular cover 2, the position and the length of the deflector in the design annul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com