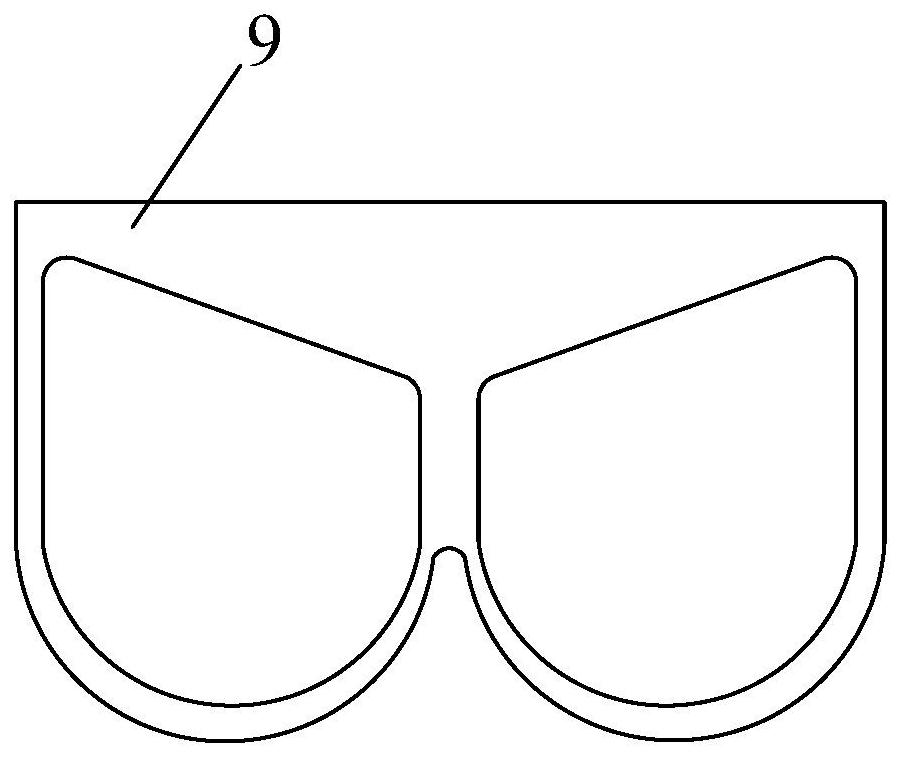

Power frequency furnace with W-shaped melting channel and using method thereof

A technology of power frequency furnace and melting groove, which is applied to the field of power frequency furnace with W-shaped melting groove, can solve the problems of low heat transfer efficiency, aging and wear of melting groove refractory materials, etc., so as to shorten melting time, avoid aging, and reduce electricity consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]The industrial frequency furnace with W-shaped melting channel and its application method are the first practical technology successfully developed on the 400kW T2 copper melting furnace in 2003, and used on the 400kW T2 copper melting furnace. The molten copper in the W-shaped melting channel 5 in the melting furnace has an electromagnetic stirring effect, and the electric energy is converted into heat by the resistance of the liquid metal in the W-shaped melting channel 5, and is quickly transferred to the melting furnace chamber 4. Not only can the W-shaped The temperature difference between the melting channel 5 and the melting furnace chamber 4 is reduced to 10-20°C, and the surface heat load of the refractory material of the W-shaped melting channel 5 can also be reduced. Compared with the traditional equal-section single melting channel, the energy saving can reach 20-30%. .

Embodiment 2

[0049] The W-shaped melting channel 5 in the present invention was adopted and applied in the transformation of the 400kW (1.5 tons / hour) brass melting furnace of Jintian Copper Rod Company in 2005. The transformed 400kW brass melting furnace not only simplifies the sensor The production, installation and maintenance of the shell have reduced the power consumption, and the actual life of the melting channel has been significantly extended, and has received good results. The modified 400kW brass melting furnace has been reduced from the original 350kwh / ton to The existing 280kwh / ton has greatly improved the production efficiency of the enterprise and reduced the production cost of the enterprise.

[0050] working principle:

[0051] When in use, the iron core 6 is energized, and the coil 7 generates a magnetically induced current. At this time, the coil 7 is used as a primary coil; due to the characteristic of metal resistance, the melting channel mold 9 is equivalent to a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com