A nested gas-liquid-solid cyclone separation device

A cyclone separation device, a gas-liquid-solid technology, is used in the production of fluids, wellbore/well components, earth-moving drilling, etc., and can solve the problems affecting the efficiency of cyclone separation, low efficiency, complicated and difficult processing of helical structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings:

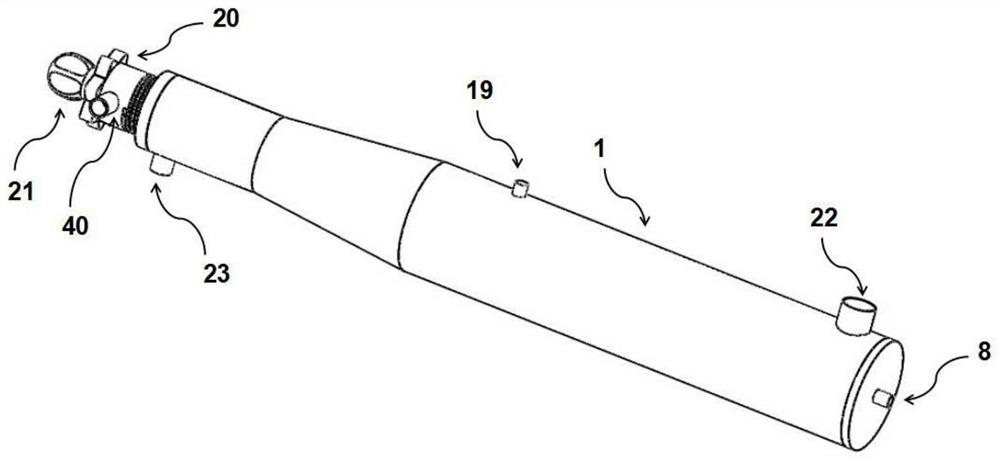

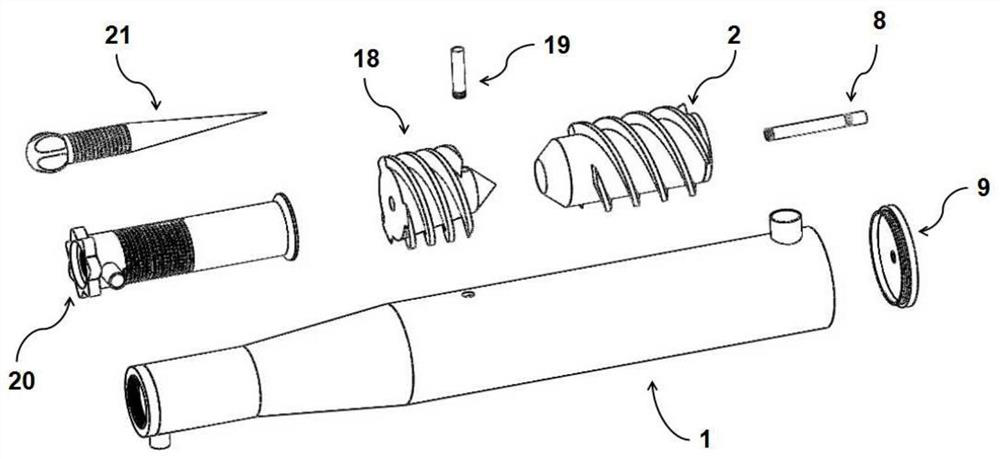

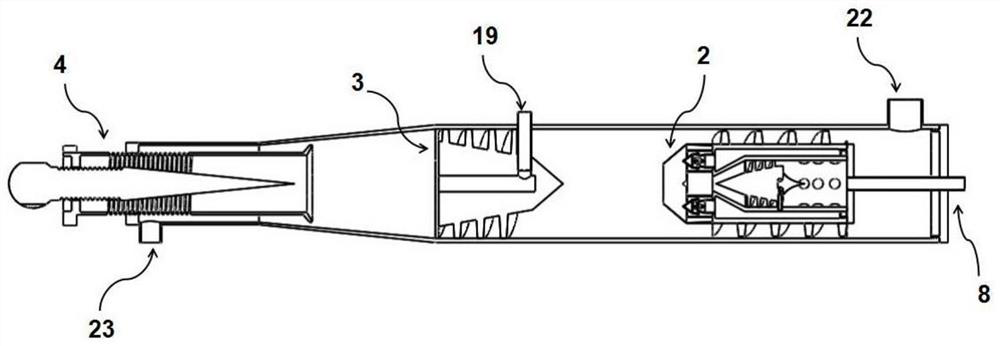

[0050] The overall appearance of this nested gas-liquid-solid cyclone separator is as follows figure 1 As shown, the gas-liquid-solid three-phase mixed liquid enters the outer sleeve 1 from the liquid inlet 22 for separation, the gas phase is discharged through the exhaust pipe 8, the sand phase is discharged from the sand discharge port 23, and the overflow liquid is discharged through the overflow flow pipe 19. The underflow liquid is discharged through the underflow pipe 40 . The explosion diagram of the nested gas-liquid-solid cyclone separator is as follows figure 2 As shown, it is mainly composed of an outer sleeve 1, a gas phase separation module 2, an exhaust pipe 8, an outer end sealing disc 9, a gradual spiral flow channel 18, an overflow pipe 19, an inner sleeve 20, and a threaded bottom cone 21. image 3 It is a cross-sectional view of the nested gas-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com