Inorganic nano protective coating, preparation method thereof and aluminum strip anticorrosive coating

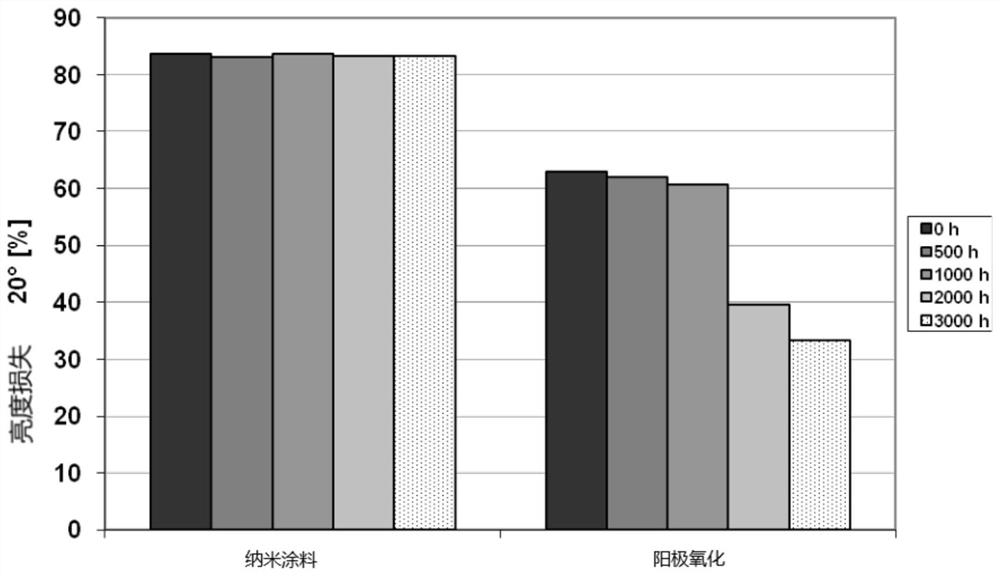

A protective coating, inorganic nanotechnology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of thickness fluctuation range, poor anti-corrosion protection effect, etc., to achieve the effect of improving aesthetics, small thickness fluctuation and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to the first aspect of the embodiments of the present invention, there is provided a method for preparing an inorganic nano protective coating, which is applied to an anodized aluminum strip, including the following steps 1-4.

[0037] Step 1: Add a polar alcohol solvent with a mass ratio of 10%-25% into the first reaction kettle, start the stirrer and stir slowly; wherein, the stirring rate is 500rpm-800rpm.

[0038] Specifically, the polar alcohol solvent includes at least one of the following: ethanol, isopropanol, n-butanol, methanol, and ethylene glycol.

[0039] Step 2: Take 15%-75% silane without additional functional groups in mass ratio and add it to the first reaction kettle in a stirring state, continue stirring for 25-35min to obtain mixture A (will contain polar alcohols, silane The precursor of its reaction product is called mixture A); wherein, the stirring rate is 500rpm-800rpm.

Embodiment

[0051] Take isopropanol solvent with a mass ratio of 20% and add it to the first reaction kettle, start the mixer and stir slowly at a rate of 600rpm; take 20% n-octyltriethoxysilane and 20% γ-shrinkage Glyceryl ether oxypropyltrimethoxysilane was sequentially added into the first reaction kettle in a stirring state, and the stirring was continued at 600 rpm for 30 min to obtain a mixture A. Take acidic silica sol with a mass ratio of 85% and deionized water with a mass ratio of 10%-20% into the second reaction kettle in turn, start stirring at a rate of 600rpm, and use 0.1mol / ml hydrochloric acid solution to the second reaction The pH of the mixture in the kettle was adjusted to 2.5-3 to obtain mixture B. Add mixture B to mixture A in a stirring state according to the component 1:3, when the temperature rises to 60°C-70°C, use external cooling water to cool the temperature to 18°C-25°C for 12 hours to obtain inorganic nano-protection coating. The inorganic nano protective c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com