Preparation method of V-shaped granular porous starch

A technology of porous starch and granules, which is applied in the field of starch modification, can solve the problems of limiting the application range of porous starch, limited porous starch adsorption performance, poor water solubility and adsorption performance, etc., and achieves improved reactivity, loose specific surface area and water absorption performance. Improved oil absorption capacity and high adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

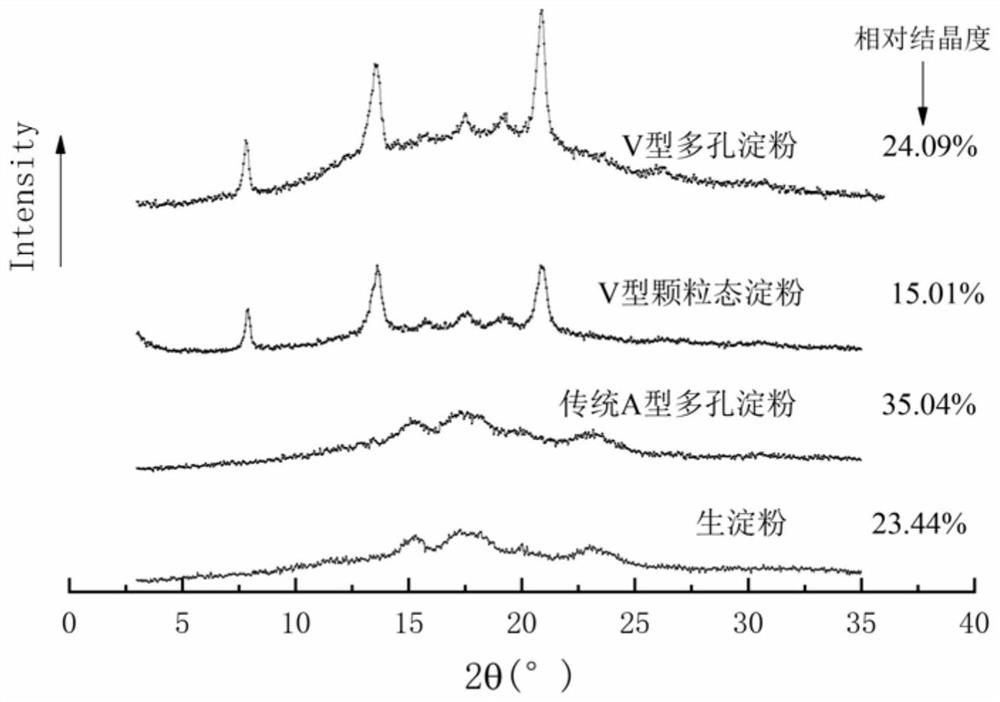

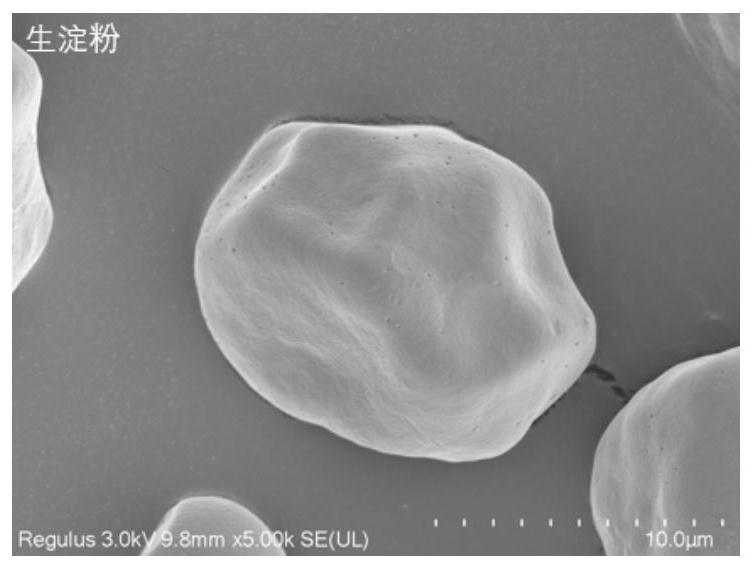

[0056] Embodiment 1: A kind of preparation method of V-type porous starch

[0057] Weigh 40g of ordinary cornstarch and 160g of 50% ethanol and pour them into a high-temperature and high-pressure reactor for reaction. The operating parameters of the high-temperature and high-pressure reactor are: reaction temperature 100°C, reaction speed 500r / min, and reaction time 30min. After cooling down, when the temperature drops to 25°C, continue to add 4mL of mixed enzyme solution to the reaction solution (the amount of mixed enzyme solution added is 66000U / g starch, α-amylase:glucoamylase enzyme activity ratio=1:4), at 45 ℃, 400r / min enzymolysis for 4h, after the end of the enzymolysis, vacuum filter, wash 2-3 times with 95% ethanol, dry at 110℃ for 2h, crush, pass through 80 mesh sieve to get V-type porous starch . The specific surface area of the V-shaped porous starch is 39.94㎡ / g, the average pore diameter is 27.61nm, the oil absorption rate is as high as 528.58%, and the water ...

Embodiment 2

[0058] Embodiment 2: a kind of preparation method of V-type porous starch

[0059] Weigh 40.00g of ordinary cornstarch and 160.00g of 60% ethanol and pour them into a high-temperature and high-pressure reactor for reaction. The operating parameters of the high-temperature and high-pressure reactor are: reaction temperature 130°C, reaction speed 500r / min, and reaction time 30min. After cooling down, when the temperature drops to 45°C, continue to add 4mL of mixed enzyme solution to the reaction solution (the amount of mixed enzyme solution added is 66000U / g starch, α-amylase:glucoamylase enzyme activity ratio=1:4), 45°C , enzymolysis under the condition of 300r / min for 6h, after the end of the enzymolysis, use a vacuum filter to filter, wash with 95% ethanol for 2-3 times, dry at 110°C for 2h, crush and pass through a 80-mesh sieve. Obtained V-type porous starch. The specific surface area of the V-shaped porous starch is 9.99㎡ / g, the average pore diameter is 26.48nm, the oil...

Embodiment 3

[0060] Embodiment 3: a kind of preparation method of V-type porous starch

[0061] Weigh 40.00g of ordinary cornstarch and 160.00g of 50% ethanol and pour them into a high-temperature and high-pressure reactor for reaction. The operating parameters of the high-temperature and high-pressure reactor are: reaction temperature 100°C, reaction speed 500r / min, and reaction time 30min. After cooling down, when the temperature drops to 25°C, continue to add 4mL of mixed enzyme solution to the reaction solution (the amount of mixed enzyme solution added is 66000U / g starch, α-amylase:glucoamylase enzyme activity ratio=1:4), 25°C , under the condition of 900r / min for 6h, after the end of the enzymolysis, vacuum filter, wash 2-3 times with 95% ethanol, dry at 110°C for 2h, pulverize and pass through 80 mesh sieve to get V-shaped porous starch. The specific surface area of the V-shaped porous starch is 14.97㎡ / g, the average pore diameter is 27.1274nm, the oil absorption rate is as high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com