Preparation method of high-thermal-conductivity net-size silicon nitride ceramic substrate

A technology of silicon nitride ceramics and net size, which is applied in the field of preparation of high thermal conductivity and net size silicon nitride ceramic substrates, which can solve the problems of low flatness, uneven thickness, substrate foaming, etc., and achieve high thermal conductivity , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

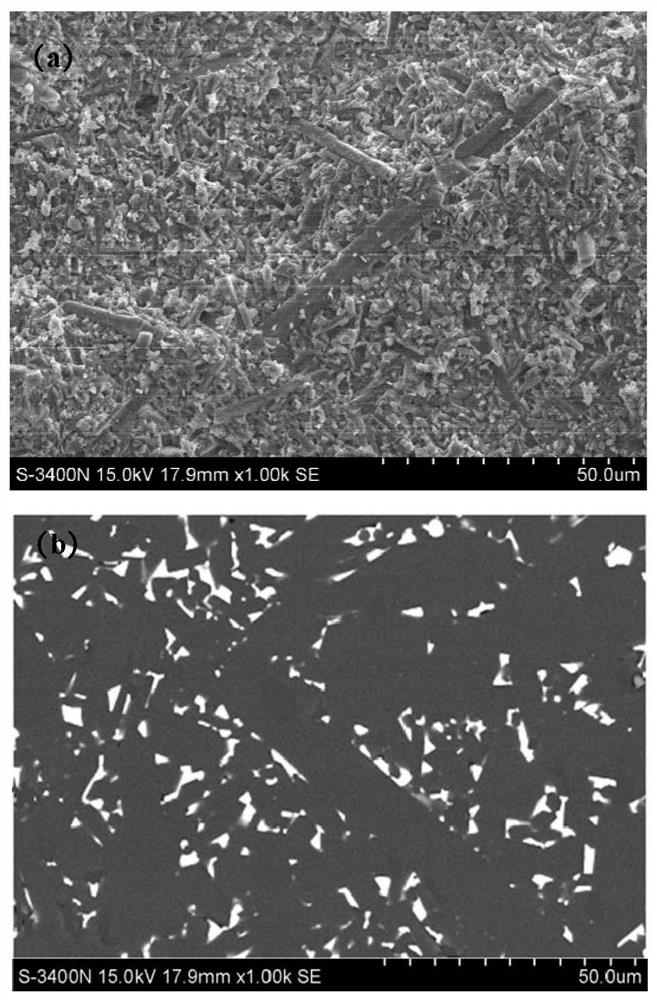

Image

Examples

preparation example Construction

[0036] Preparation of agglomerate-free and bubble-free slurries. At least one of silicon nitride powder and silicon powder, sintering aid, dispersant, defoamer, binder and plasticizer in a protective atmosphere (such as N 2 atmosphere, the pressure can be 0.1MPa) after ball milling and mixing, and then vacuum degassing to prepare a mixed slurry without agglomeration and bubbles. In the ball milling process, silicon nitride ceramic grinding balls are used. The sintering aids can be rare earth oxides and alkaline earth metal oxides. The rare earth oxide contains at least Y 2 o 3 , the alkaline earth metal oxide contains at least MgO. The molar ratio between the rare earth oxide and the alkaline earth metal oxide may be (1.0-1.4): (2.5-2.9). Wherein when silicon powder is contained, the silicon powder content may be 75-100 wt%. Vacuumize the prepared slurry to remove air bubbles, the vacuum degree can be -0.1~-10kPa, and the degassing time can be 6~24h.

[0037] Preparatio...

Embodiment 1

[0045] First, the starting ceramic powder (silicon nitride 95g), sintering aid (5g, Y 2 o 3 : MgO=1.2:2.5, molar ratio), defoamer (oleic acid, 0.5g), dispersant (PEG, 0.5g), grinding ball (silicon nitride ball, 200g), organic solvent (absolute ethanol, 80g ) into a sealed nylon ball mill jar, and N 2 Atmosphere protection, ball mill mixing 4h under 100rpm; Further add binding agent (PVB, 7g) and plasticizer (DBP, 4g) in above-mentioned slurry, continue under N 2 After ball milling for 8 hours under the protection of the atmosphere, a uniformly dispersed and non-agglomerated slurry was obtained;

[0046] Secondly, vacuumize the prepared slurry to remove air bubbles for 12 hours, and the vacuum degree is -0.5kPa;

[0047] Subsequently, at N 2 Under a protective atmosphere, use a cylindrical scraper to tape-cast the above-mentioned slurry after removing air bubbles, and control the height of the scraper so that the thickness of the casting film blank is accurately controlled ...

Embodiment 2-5

[0054] Raw material ratio and composition, technical process refer to Example 1, specific parameters such as slurry preparation, vacuum degassing, tape casting, biscuit shaping, debonding and sintering process are as shown in Table 1, and the characteristics of the prepared substrate material are as follows Table 2 shows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com