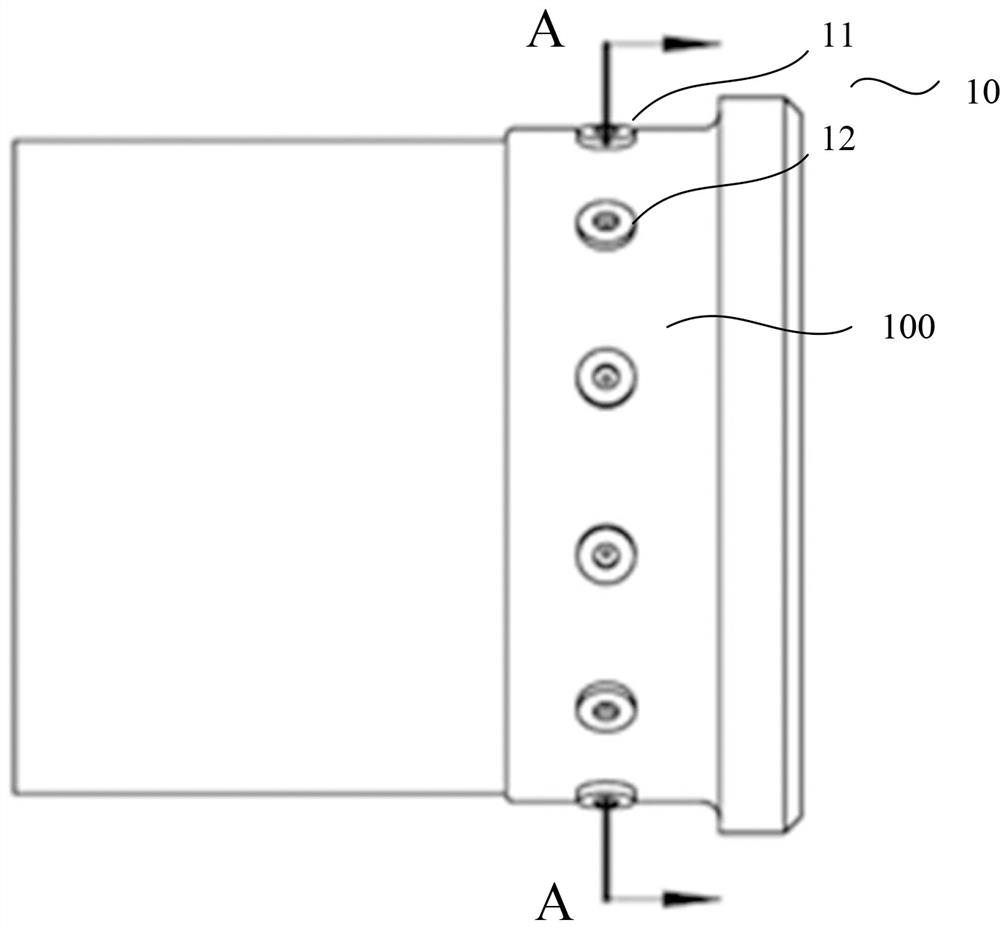

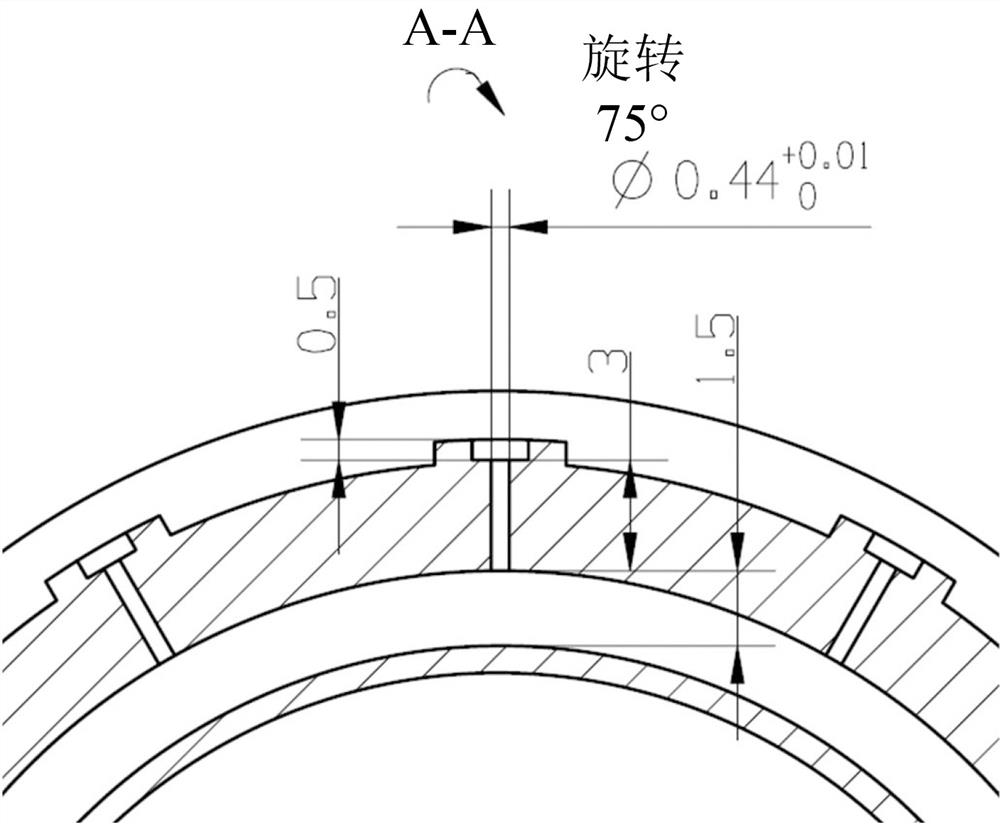

Processing method of fuel injection hole and fuel injection nozzle

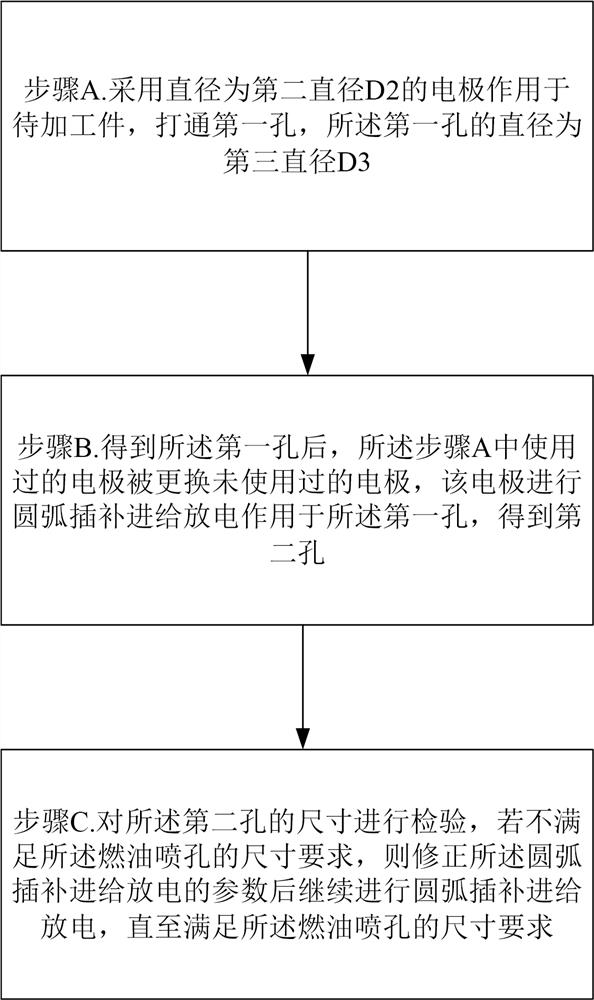

A processing method and fuel nozzle technology, applied in the field of processing and manufacturing, can solve the problems of low processing efficiency, damage to the wall, easy processing taper and rounded corners of orifices, etc., so as to improve processing consistency, reduce flow fluctuation, improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A variety of different implementations or examples for implementing the described subject technical solutions are disclosed below. In order to simplify the disclosure, the following describes the specific examples of each component and arrangement, of course, these are only examples, not limiting the protection scope of the present invention. "One embodiment," "an embodiment," and / or "some embodiments" mean a feature, structure, or characteristic that relates to at least one embodiment of the present application. Therefore, it should be emphasized and noted that two or more references to "an embodiment" or "an embodiment" or "an alternative embodiment" in different places in this specification do not necessarily refer to the same embodiment . In addition, certain features, structures or characteristics of one or more embodiments of the present application may be properly combined.

[0037] The flow chart is used in this application to illustrate the operations performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com