Processing method for better controlling spherical degree of irregular spherical glass

A processing method and irregular technology, which is applied in the processing field of better controlling the sphericity of irregular spherical glass, can solve the problems of lowering the control requirements of the heating furnace temperature, and the difficulty of forming large spherical special-shaped glass, so as to reduce the requirements and benefit large-scale production. Good effect of scale promotion and curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

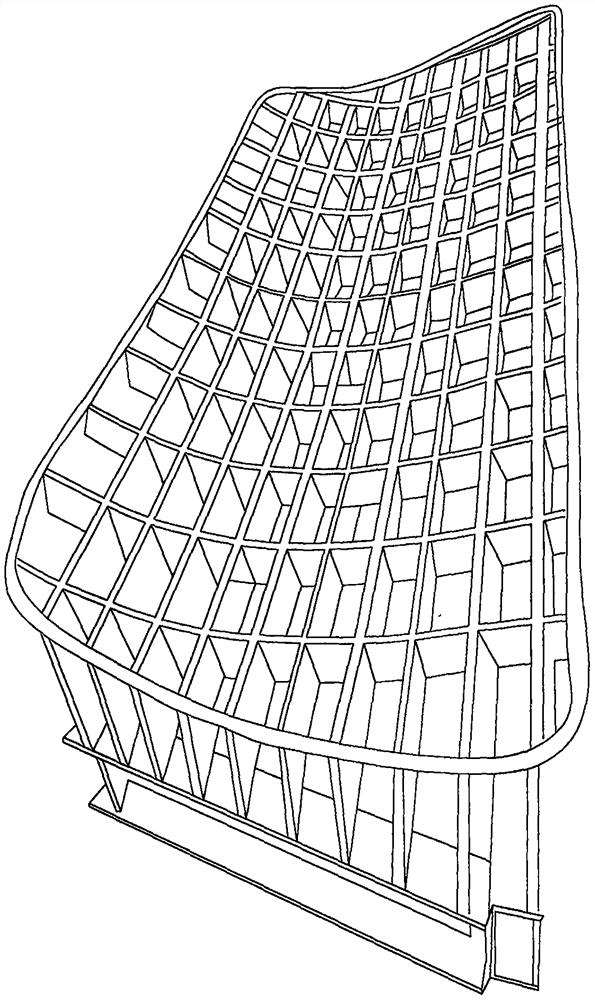

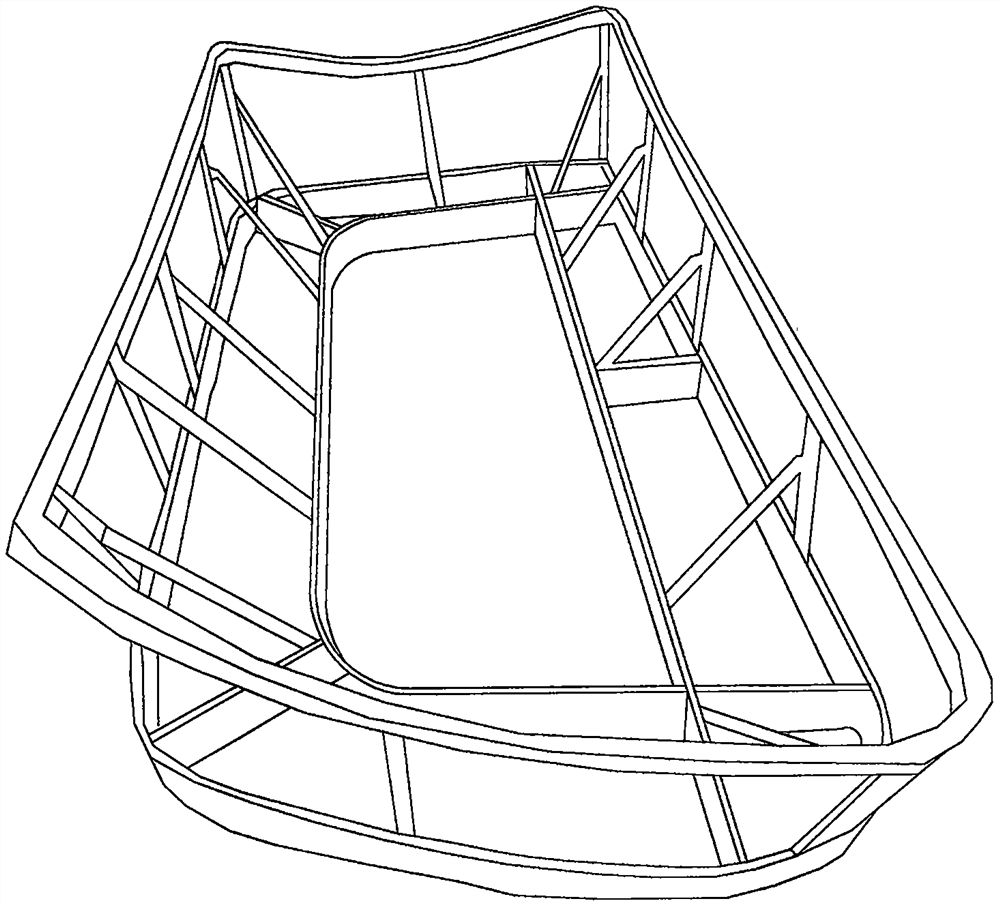

[0016] (1) Making molds: use 5mm thick hot-rolled steel plates to cut out slats, assemble and weld them together, use 5cm*10cm channel steel for reinforcement at the base, and weld together with 8-10mm cold-drawn steel rods or stainless steel rods at the edges, such as figure 1 shown;

[0017] (2) Select high-temperature fiber cloth to spread on the mold;

[0018] (3) Lay the flat glass onto the high temperature fiber cloth;

[0019] (4) Heat forming: use a heating furnace to heat the mold in step (1) and the flat glass in step (3) to the softening temperature of the flat glass in step (3), and the flat glass is attached to the cavity of the mold The surface is shaped into a curved shape;

[0020] (5) Cooling and taking out the workpiece: After the mold and the flat glass are cooled, take out the curved glass formed from the flat glass, and after deburring the curved glass, the finished curved glass can be obtained.

[0021] Adopt the method of embodiment to carry out 50 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com