Method for preparing ultrathin aluminum-magnesium layered composite material through low-temperature rolling

A layered composite material, low-temperature rolling technology, applied in metal rolling, temperature control, metal rolling, etc., can solve the problems of low strength and low density, achieve high interface quality, low equipment requirements, and flexible application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0065] For example: preparation of 2A12-Al / AZ31-Mg layered composite sheet and strip with a thickness of 4mm;

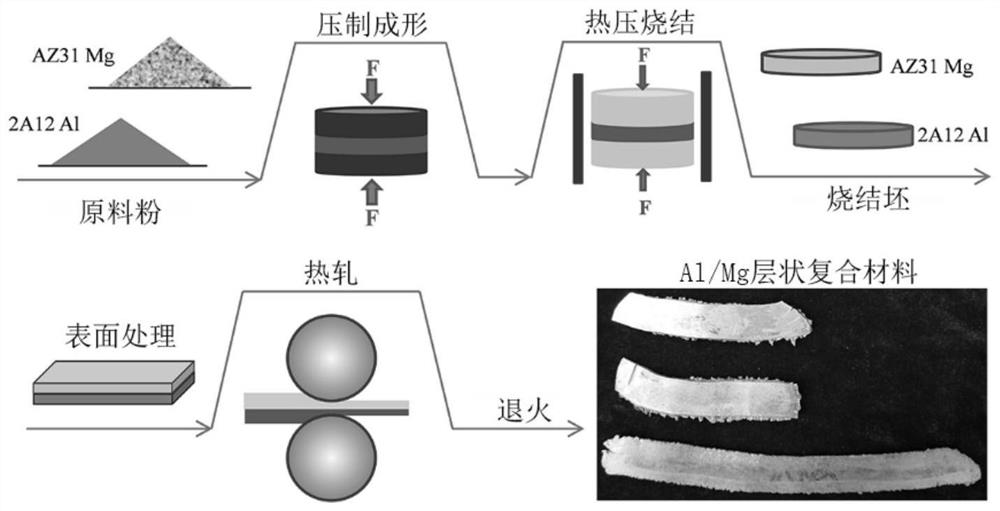

[0066] According to the production method of the present invention, the 250~300 order spherical 2A12 aluminum alloy powders produced by Changsha Tianjiu Metal Materials Co., Ltd. and the 150 order irregular shape AZ31 magnesium alloy powders produced by Tuopu Metal Materials Co., Ltd. are used as raw material powder (its chemical composition In line with the provisions of GB / T3190). First, weigh the corresponding weights of 2A12 aluminum alloy powder and AZ31 magnesium alloy powder, and use a single-column or four-column hydraulic press to press and form 10mm thick billets under a pressure of 400MPa; then, under vacuum conditions (vacuum degree is 1*10 -1 ~1*10 -3 ), pressurize and sinter the aluminum alloy and magnesium alloy blanks at 550°C for 120min, and the sintering pressure is 10MPa; since the thickness of the aluminum alloy sintered blank and the magnesium a...

Embodiment 3

[0068] For example: prepare 1mm 6082-Al / AZ31-Mg layered composite sheet and strip;

[0069] Its preparation process is consistent with the process of Example 1, the difference is that the aluminum alloy powder raw materials are different. The overall tensile strength of the obtained sample is 315.8MPa, and the interfacial shear strength is 49.2MPa; the yield of the product is greater than or equal to 97%.

Embodiment 4

[0071] For example: prepare 0.8mm 2A12-Al / AZ61-Mg layered composite sheet and strip;

[0072] Its preparation process is consistent with the process of Example 1, the difference is that the magnesium alloy powder raw materials are different. The overall tensile strength of the obtained sample is 355.6MPa, and the interfacial shear strength is 51.9MPa; the yield of the product is greater than or equal to 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com