Spiral conveyor with auxiliary blades and spiral discharging sedimentation centrifuge

A technology of screw conveyor and auxiliary blade, applied in the field of solid-liquid separation, can solve the problems of low solid content in light phase and poor separation effect, and achieve the effect of low cost, increased area, and improved separation factor Fr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

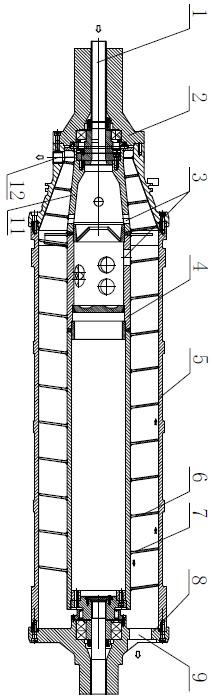

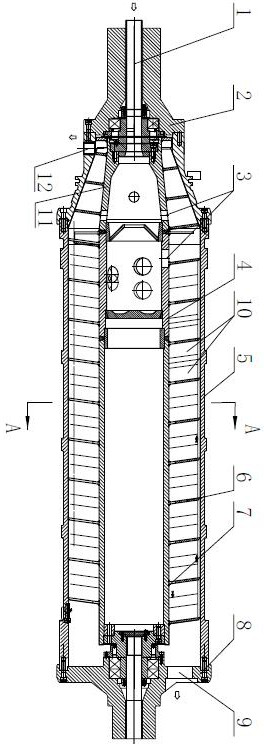

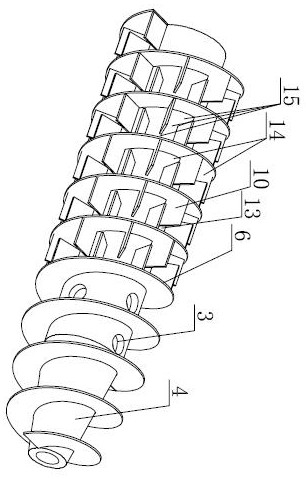

[0030] Such as image 3 , Figure 4 As shown, the screw conveyor with secondary blades of the present invention is between the screw blades 6 of the existing conventional screw conveyor, and several secondary blades 10 are added, and the width of the secondary blades 10 is less than the joint of the screw blades 6. The two adjacent auxiliary blades 10 are arranged alternately, which further divides the original continuous and complete spiral channel space between the spiral blades 6 into meandering flow channels 15, thereby prolonging the separation path length of the suspension and effectively improving the separation effect.

[0031] The auxiliary blade 10 added in this embodiment is a plane straight blade, arranged along the radial direction of the screw conveyor, the bottom side of the root is welded to the outer periphery of the inner cylinder 4, and one side is welded to the helical blade 6, that is The left edge of a part of the auxiliary blades 10 in each helical spac...

Embodiment 2

[0036] Such as Figure 5 As shown, in this embodiment, the plane straight blades in Embodiment 1 are changed to curved blades, and the auxiliary blade 10 has a certain curvature radian, and the curved convex direction of the curved surface is consistent with the direction of rotation of the drum, that is, the heavy phase particles in the suspension It will move outward along the convex surface of the curved blade. This setting can effectively increase the centrifugal force and make the heavy phase particles easy to settle.

Embodiment 3

[0038] Such as Figure 6 , Figure 7 As shown, in this embodiment, the auxiliary blades 10 arranged along the axial direction of the drum in the first embodiment are deflected at a certain angle, Figure 7 The angle α between the middle and auxiliary blades 10 and the central axis of the drum is within 45 degrees, preferably 5-30 degrees, adjacent blades are arranged in parallel, and the deflection directions are consistent. In this embodiment, the auxiliary blade 10 is arranged in the rear spiral channel of the discharge hole 3, which can reduce the conveying resistance in the drying area of the drum cone section 11, and facilitate the discharge of solid-phase materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com