Photocatalytic self-cleaning loose nanofiltration membrane and preparation method and application thereof

A self-cleaning, nanofiltration membrane technology, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of low flux and low quantum efficiency in dye wastewater treatment, and achieve increased sewage treatment capacity and photocatalytic quantum efficiency. High, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

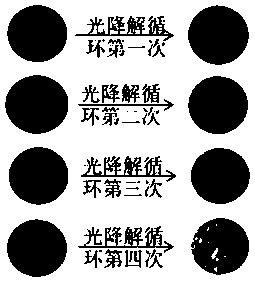

Image

Examples

Embodiment 1

[0027] A photocatalytic self-cleaning loose nanofiltration membrane, the preparation process is as follows:

[0028] 1) Preparation of ultra-thin nanosheet Zn-TCPP: Weigh 16mg of pyrazine, 90mg of zinc nitrate, 40mg of polyvinylpyrrolidone (PVP) and dissolve in 240ML (DMF: ethanol 3:1) mixed solution, which is recorded as mixed solution 1, Weigh 80mg of tetraphenylcarboxyporphine and dissolve it in 80ML (DMF:ethanol: 3:1) mixed solution, which is recorded as mixed solution 2. Mixed solution 2 is dropped into mixed solution 1 drop by drop, then ultrasonicated for 10min, and reacted at 80°C After 24 hours, centrifuge at 12000 r and wash with ethanol to obtain a solid. The scanning electron micrographs of the obtained Zn-TCPP nanosheets are shown in figure 1 A, it can be found that Zn-TCPP is a nanosheet with a size of several hundred nanometers;

[0029] 2) Dissolve melamine and Zn-TCPP ultra-thin nanosheets in the water phase, dissolve TMC in n-hexane (oil phase), the mass co...

Embodiment 2

[0032] The mass concentration of Zn-TCPP in the water phase in step 2) is 0.01%, and the others are the same as in Example 1.

Embodiment 3

[0034] The mass concentration of Zn-TCPP in the water phase in step 2) is 0.02%, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com