Multi-aspect disinfecting and cleaning equipment for medical instruments

A technology for cleaning equipment and medical equipment, applied in the field of disinfection and cleaning equipment, can solve the problems of low degree of automation, single sterilization method, and low safety factor, so as to improve the degree of automation of equipment, improve equipment safety, and reduce the risk of touching equipment The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

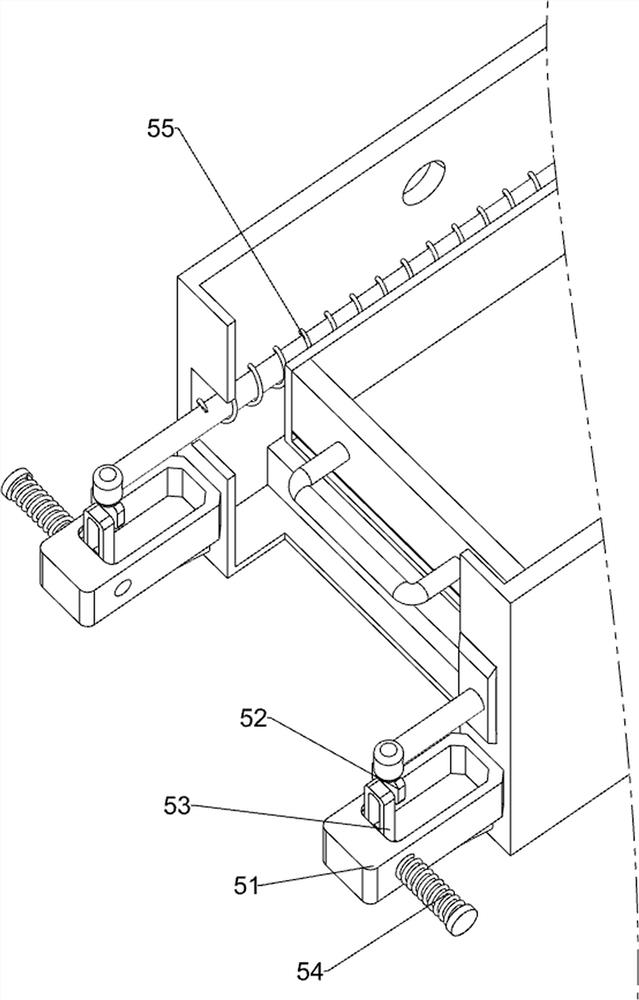

[0068] A multi-faceted disinfection and cleaning equipment for medical instruments, such as figure 1 As shown, it includes a bottom plate 1, a support rod 2, a connecting plate 3, a high-temperature disinfection mechanism 4, and a locking mechanism 5. The top of the bottom plate 1 is evenly provided with a support rod 2, and the top of the support rod 2 is connected with a connecting plate 3, and the top of the connecting plate 3 A high-temperature disinfection mechanism 4 is provided at the side and rear, and a locking mechanism 5 is provided at the middle of the front side of the high-temperature disinfection mechanism 4 .

[0069]When medical staff sterilize medical instruments, the efficiency of comprehensive disinfection is low. The invention helps people improve the efficiency of comprehensive disinfection of medical instruments. First, put the instruments to be sterilized into the high-temperature disinfection mechanism 4, and start the high-temperature disinfection mech...

Embodiment 2

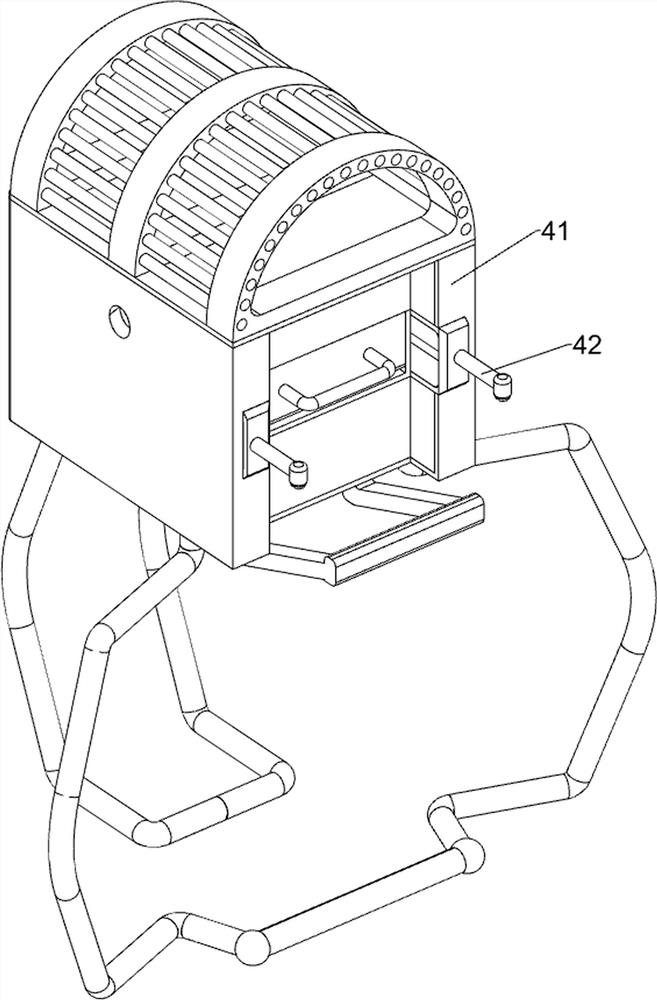

[0071] On the basis of Example 1, such as figure 2 , image 3 with Figure 4 As shown, the high-temperature disinfection mechanism 4 includes a high-temperature box 41, a first connecting rod 42, a sliding sleeve 43, a rotating storage box 44, a rotating discharge door 45 and a retaining rod 46, and the rear part of the top side of the connecting plate 3 is provided with a high-temperature box 41. The middle part of the high temperature box 41 is slidably provided with two first connecting rods 42, the rear of the first connecting rod 42 is provided with a sliding sleeve 43, the sliding sleeve 43 is slidably connected with the high temperature box 41, and the inner sides of the two sliding sleeves 43 are rotated. Rotary placement case 44 is arranged, and rotation placement case 44 anterior parts are provided with rotary discharge door 45, and high-temperature case 41 middle parts are provided with retaining bar 46, and retaining bar 46 cooperates with rotating placement case...

Embodiment 3

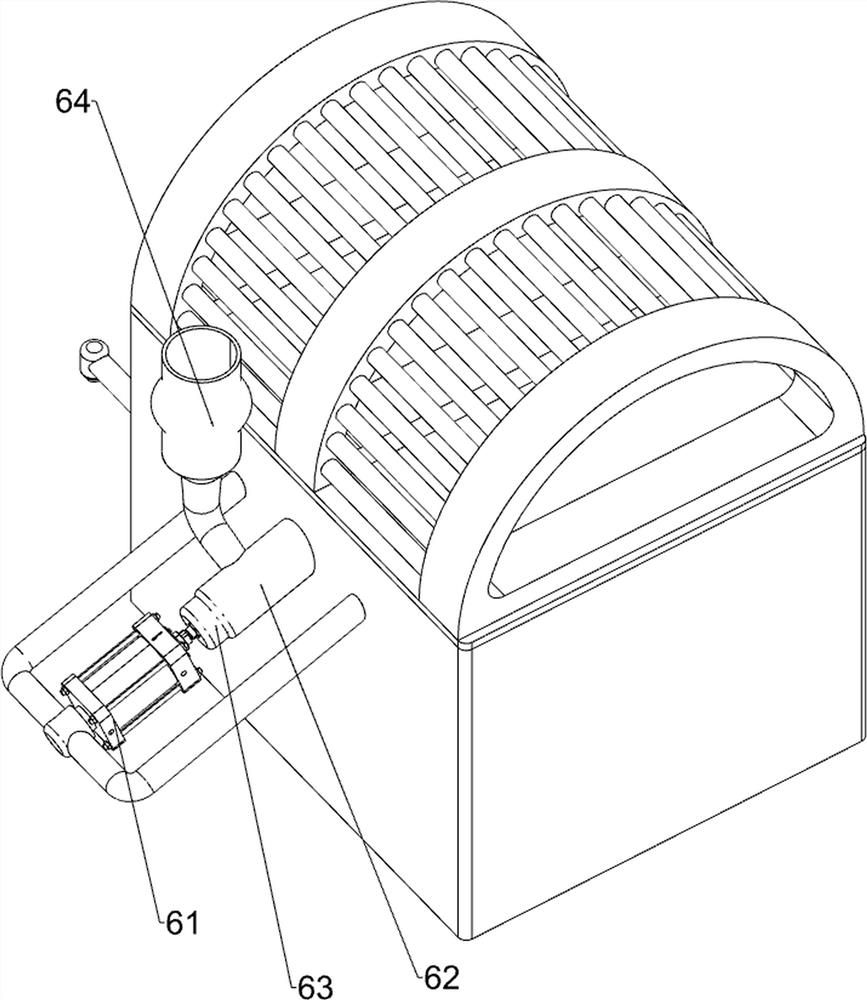

[0076] On the basis of Example 2, such as figure 1 , Figure 5 , Image 6 , Figure 7 with Figure 8 Shown, also comprise spray disinfection mechanism 6, high temperature disinfection mechanism 4 tops are provided with spray disinfection mechanism 6, spray disinfection mechanism 6 includes cylinder 61, first water outlet pipe 62, extruding pipe 63 and water storage pipe 64, high temperature box 41 Two cylinders 61 are installed on the top, and extruded pipes 63 are connected on the telescopic rods inside the cylinders 61. Two first water outlet pipes 62 are arranged on the top of the high-temperature box 41, and the first water outlet pipes 62 cooperate with the extruded pipes 63. The water outlet pipe 62 is provided with a water storage pipe 64 , and the water storage pipe 64 cooperates with the extrusion pipe 63 .

[0077] First, add medical alcohol into the water storage pipe 64, and the alcohol flows downward. Since the extrusion pipe 63 cooperates with the first outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com