Whole-process automatic cultivation equipment for greenhouse vegetables

A technology of the whole process and equipment, applied in the field of agricultural automation and facility agriculture, can solve the problems of low degree of industrialization, low degree of automation, small scale of production base, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

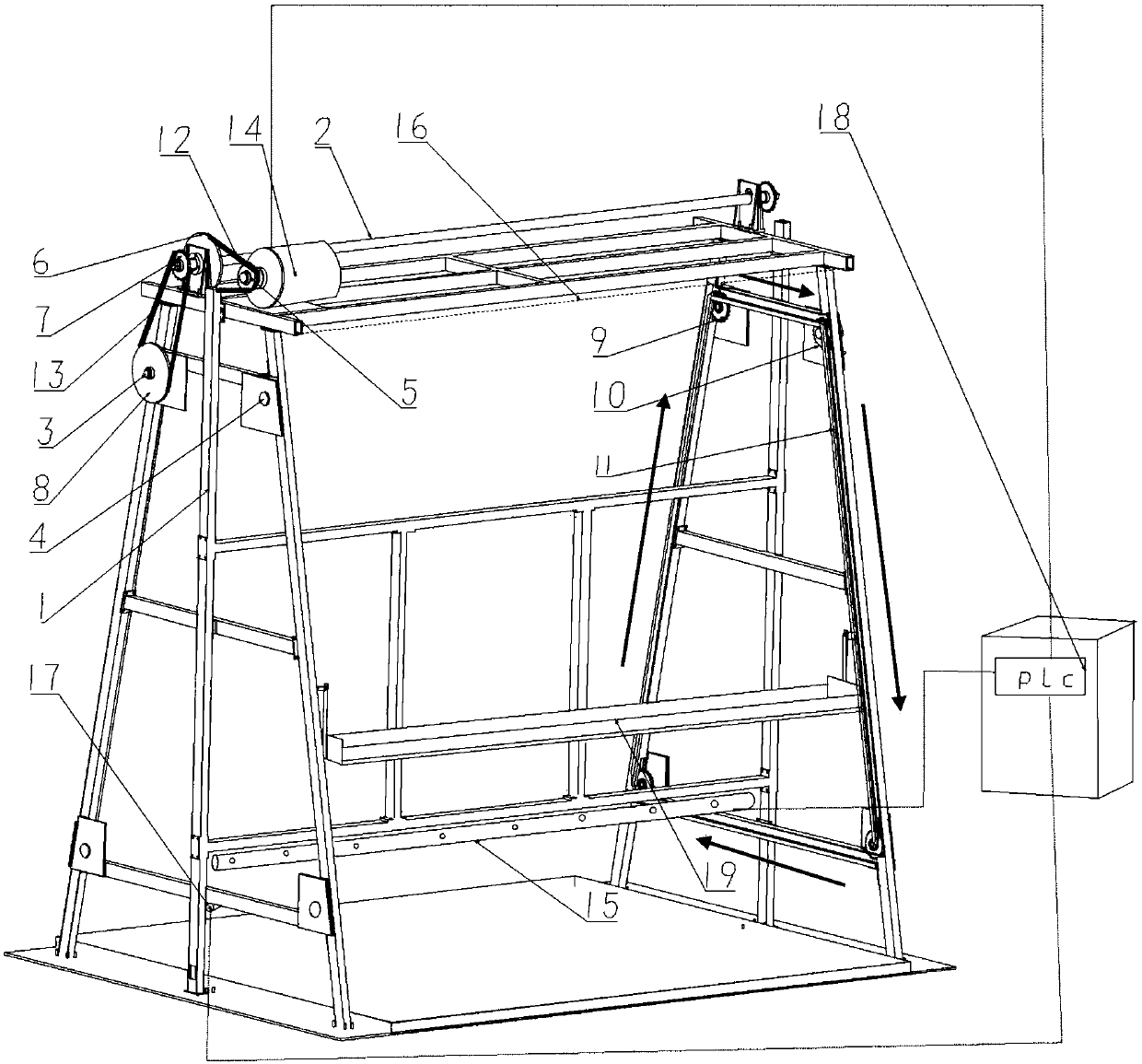

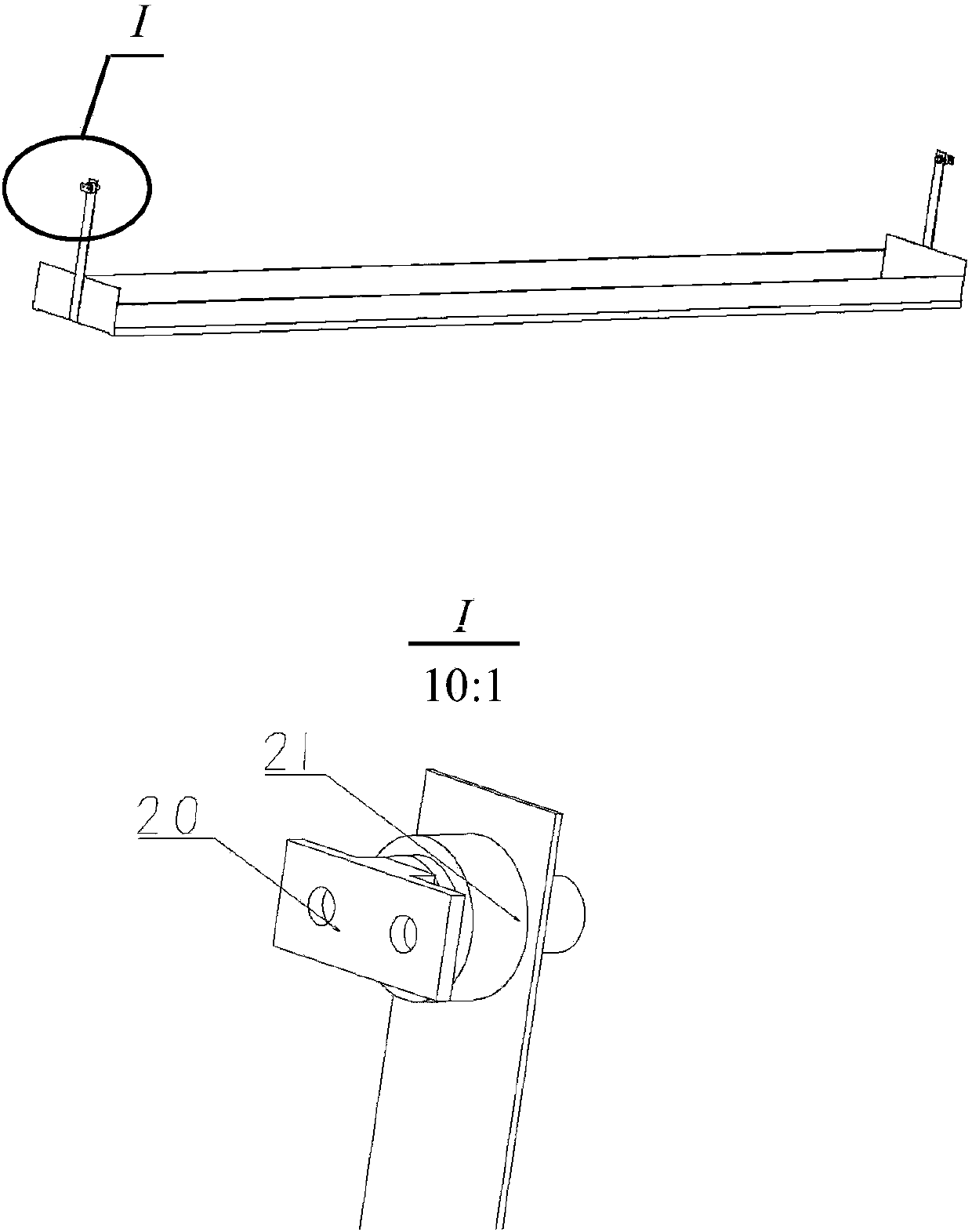

[0014] 1. A whole-process automatic cultivation equipment for greenhouse vegetables is electrical automation control mechanical equipment. Consists of load frame (1), drive shaft (2), driven shaft 1 (3), driven shaft 2 (4), sprocket 1 (5), sprocket 2 (6), sprocket 3 (7) , sprocket 4 (8), sprocket 5 (9), sprocket 6 (10), working chain (11), power chain 1 (12), power chain 2 (13), hopper (19), chain plate combination Shaft (20), walking wheel (21), reduction motor (14), solenoid valve control type water and fertilizer system (15), fill light (16), proximity switch (17) and programmable controller (18). It is characterized in that the reduction motor (14) and the driving shaft (2) are chain-driven through the sprocket 1 (5), the sprocket 2 (6) and the power chain 1 (12), and are arranged above the load-bearing frame body (1) ; Driving shaft (2) and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com