Full-automatic microcrystalline copper ball hydroforming and circulating production line and intelligent management system

A technology of hydraulic forming and management system, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of automation, informatization and intelligent factory management, difficulty in realizing equipment, inability to obtain equipment, and inability to keep up. , to achieve the effect of network and intelligent management, high degree of equipment automation, and environmental protection of the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

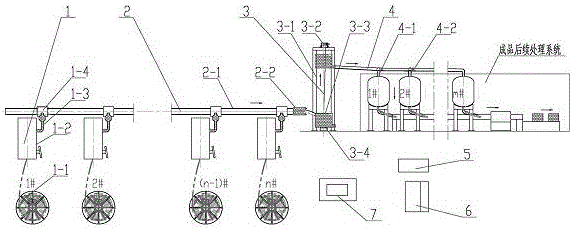

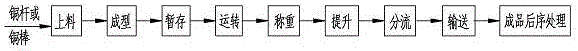

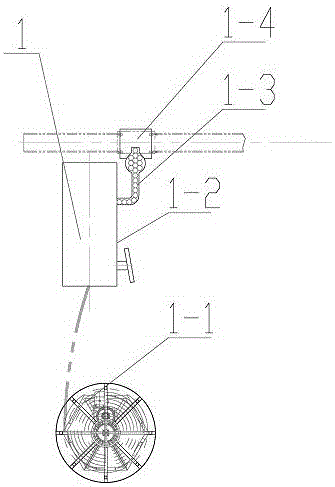

[0054] In order to achieve the above purpose, the specific embodiment of the technical solution adopted by the present invention is: design a microcrystalline copper ball automatic hydraulic forming and circulation production line and an intelligent management system, which consists of a microcrystalline copper ball automatic hydraulic forming and circulation production line, an intelligent The composition of the management system; microcrystalline copper ball automatic hydraulic forming and circulation production line includes microcrystalline copper ball automatic hydraulic forming unit 1, identification and transfer system 2, weighing and lifting system 3, diversion and conveying system 4, pneumatic control system 5. Hydraulic control system 6, electrical control system 7, and finished product post-processing system; intelligent management system consists of upper computer and corresponding management software, man-machine interface, and network equipment.

[0055] The intel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com