Airtight terminal and pressure-resistant container

A technology of air-tight terminals and pressure-resistant containers, which is used in electrical components, organic insulators, variable capacitance pump components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

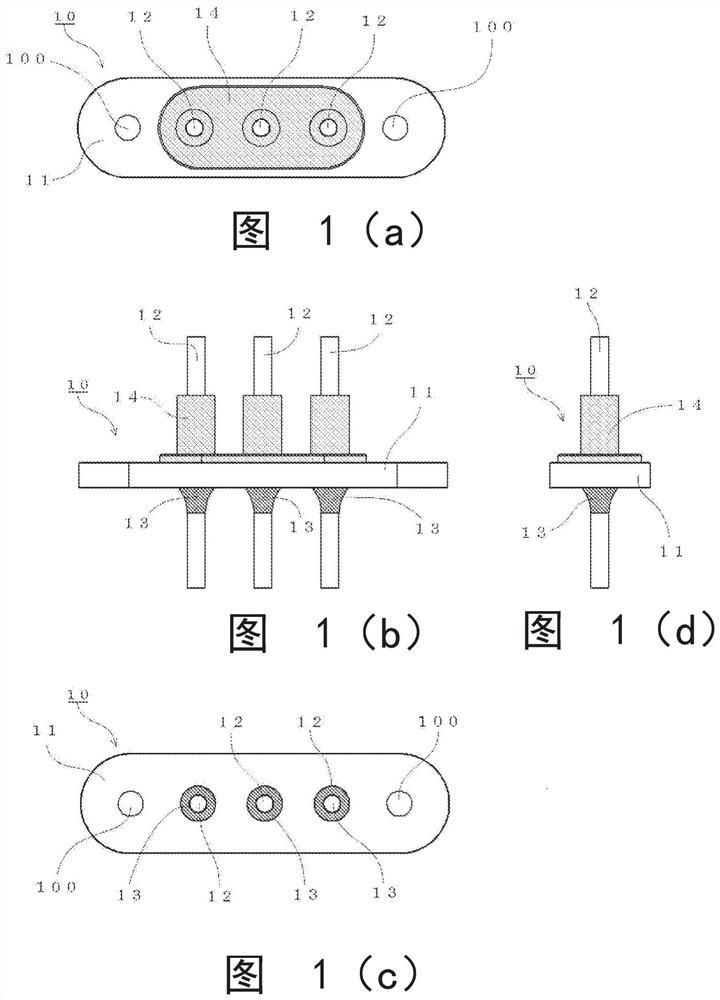

[0052] The airtight terminal 10 of Embodiment 1 involved in the present disclosure is as figure 1 As shown, it includes: a metal base 11 of carbon steel with a plurality of through holes 100 provided for screw stop and three sealing holes arranged on a straight line; The lead 12 made of Cr-iron-based alloy; the insulating material 13 of borosilicate glass that hermetically seals the metal base 11 and the lead 12 ; and the heat insulator 14 . The heat insulator 14 is a coating that covers the surfaces of the metal base 11, the pins 12 and the insulating material 13, which are located on the inner side and come into contact with the refrigerant when the airtight terminal 10 is attached to the pressure-resistant container. , is made by HNBR.

[0053] A part of the insulator 14 is along the inner layer side ( figure 1 The surface of the lead 12 in (a)) extends to cover the lead 12 except the tip portion. The other part of the heat insulator 14 covers the entire surface of the i...

Embodiment 2

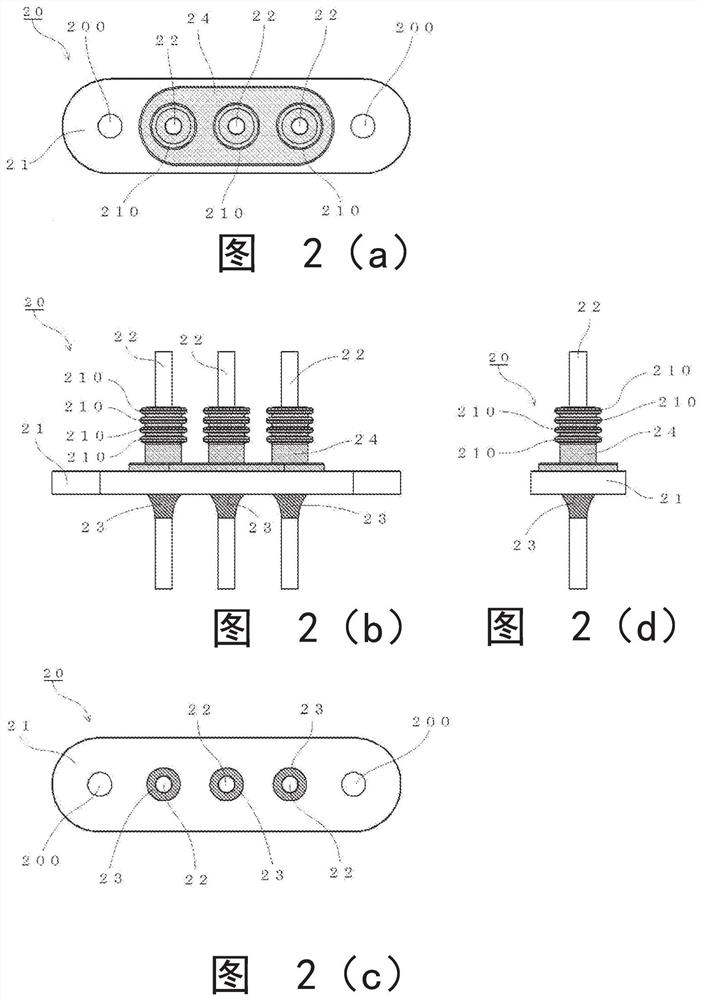

[0060] Since the airtight terminal 20 of the second embodiment uses EPDM for the heat insulator 24, it can satisfy refrigerant resistance, especially oil resistance to POE [polyol ester] oil. In addition, by using EPDM to increase the creepage distance between the inner metal base 21 and the pin 22 , tracking resistance, electrical insulation, and voltage resistance can be improved.

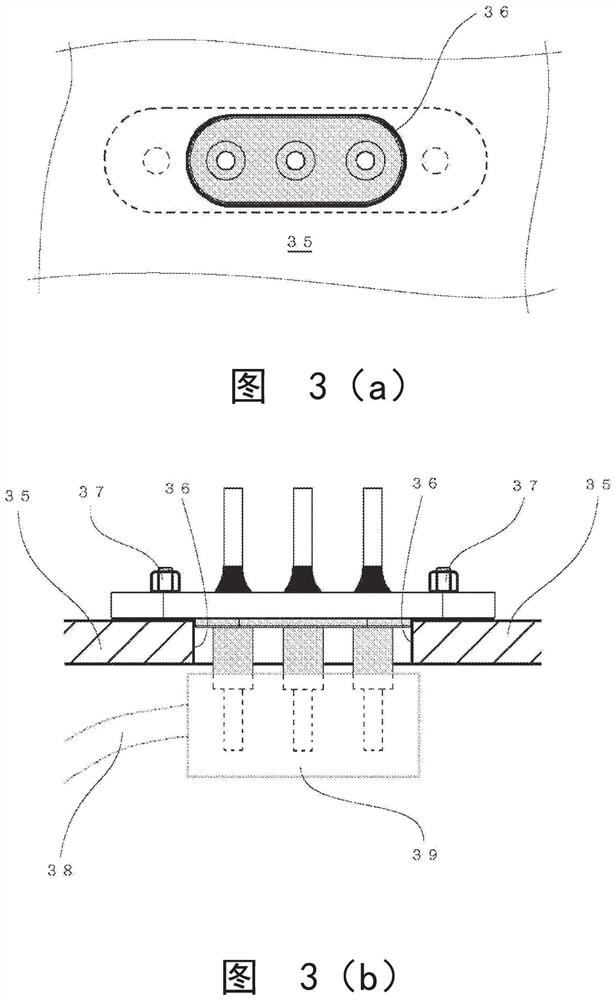

[0061] Such as image 3 As shown, after the pins are electrically connected to the motor housed inside the pressure-resistant container 35 where the air-tight terminal is installed, the air-tight terminal according to the present disclosure can be inserted into the terminal installation hole 36 of the pressure-resistant container 35, And carry out fastening and installation by screw 37 etc.

[0062] The lead of the hermetic terminal according to the present disclosure can have desired electroplating on the surface thereof. In addition, as long as the metal material which can be used for an airt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com