Injection moulding shop air conditioner and its control method

A technology for air-conditioning systems and workshops, applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as low efficiency and high energy consumption, improve efficiency, reduce energy consumption, and prevent mold The effect of condensation on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

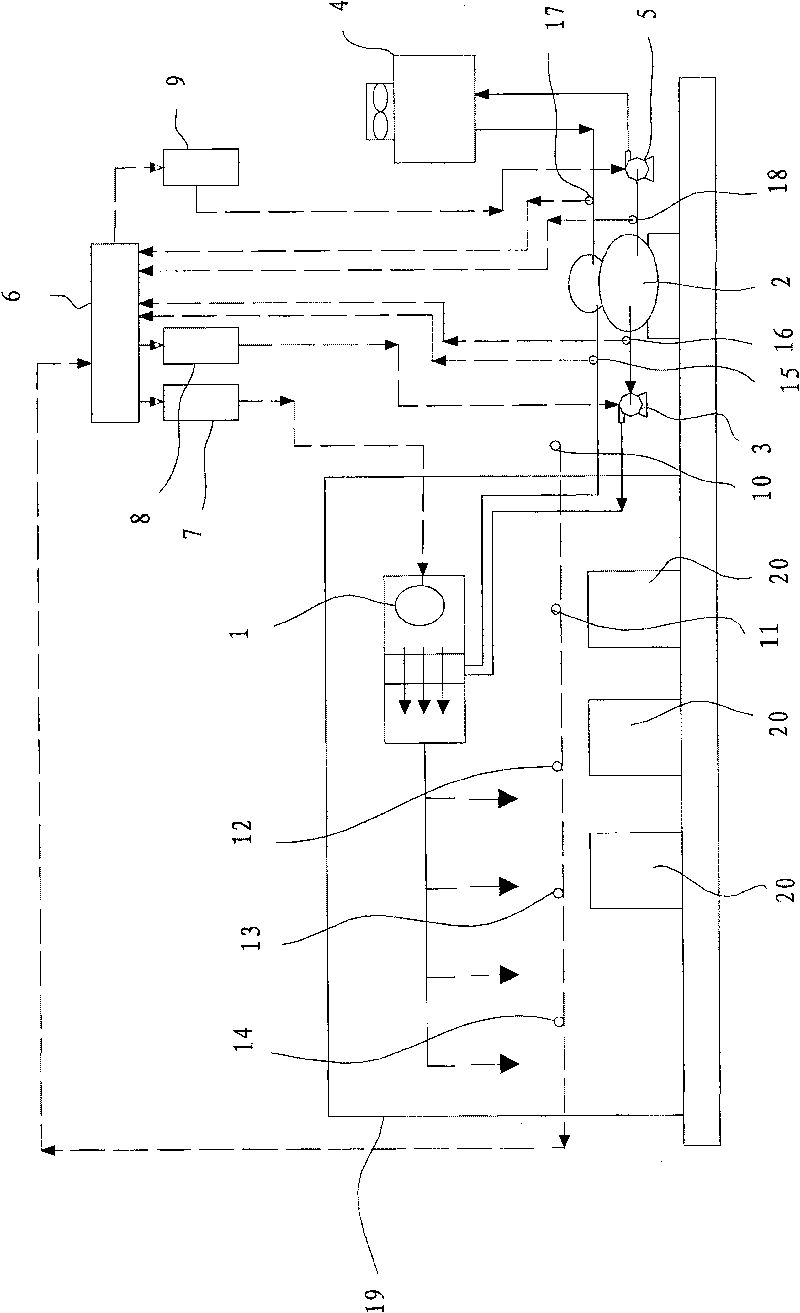

[0022] refer to figure 1 As shown, several injection molding machines 20 are set in the injection molding workshop 19. The air conditioning system used in the injection molding workshop includes an indoor fan 1 located indoors, and a refrigeration pump 3, a refrigerator 2, a cooling pump 5 and a cooling tower located outdoors. 4. There is a refrigeration cycle established by the refrigeration pump 3 between the indoor fan 1 and the refrigerator 2, and a cooling water circulation established by the cooling pump 5 between the cooling tower 4 and the refrigerator 2. The air conditioning system also includes a separate Four indoor temperature and humidity sensors 11, 12, 13, 14, a temperature and humidity sensor 10 located outside, fan frequency converter 7 and programmable controller 6 that control the speed of the indoor fan 1, wherein the temperature and humidity sensors 11, 12, 13, 14 and 15 can respectively transmit the indoor and outdoor temperature and humidity signals to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com