LNG ultralow-temperature direct-current molded line medium-voltage coaxial cable

An ultra-low temperature, cable technology, applied in the field of cables, can solve the problems of brittleness, hardening of the insulating layer and sheath layer, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention also discloses a method for preparing an LNG ultra-low temperature DC type line medium voltage coaxial cable, which includes the following steps:

[0052] Step 1: preparing the inner conductor 1;

[0053] Step 2: Wrapping the inner conductor 1 with a polyimide film tape, the overlapping rate is not less than 30%, and then sintering to form the shield 2;

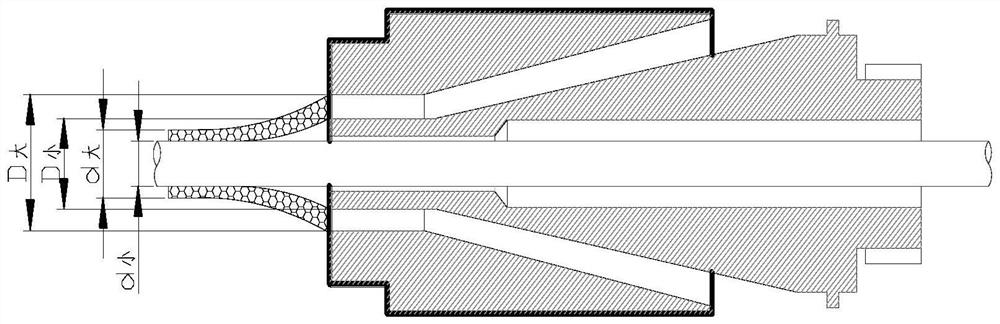

[0054] Step 3: Extrude polytetrafluoroethylene with a melt index of 6-8g / 10min outside the shielding 2 to form an insulating layer 3, and place the polytetrafluoroethylene raw material at 120± Dry in an oven at 10°C for 1±0.5h, fully dry, and set aside; the temperature of the extrusion body of the extrusion mold is controlled at 320°C to 340°C, 340°C to 360°C, and 360°C in sequence from the first zone to the fourth zone. ℃~380℃, 380℃~400℃; the temperature of the flange is controlled at 380℃~400℃, the temperature of the machine head is controlled at 375℃~410℃; the appearance of the discharge material is u...

Embodiment 1

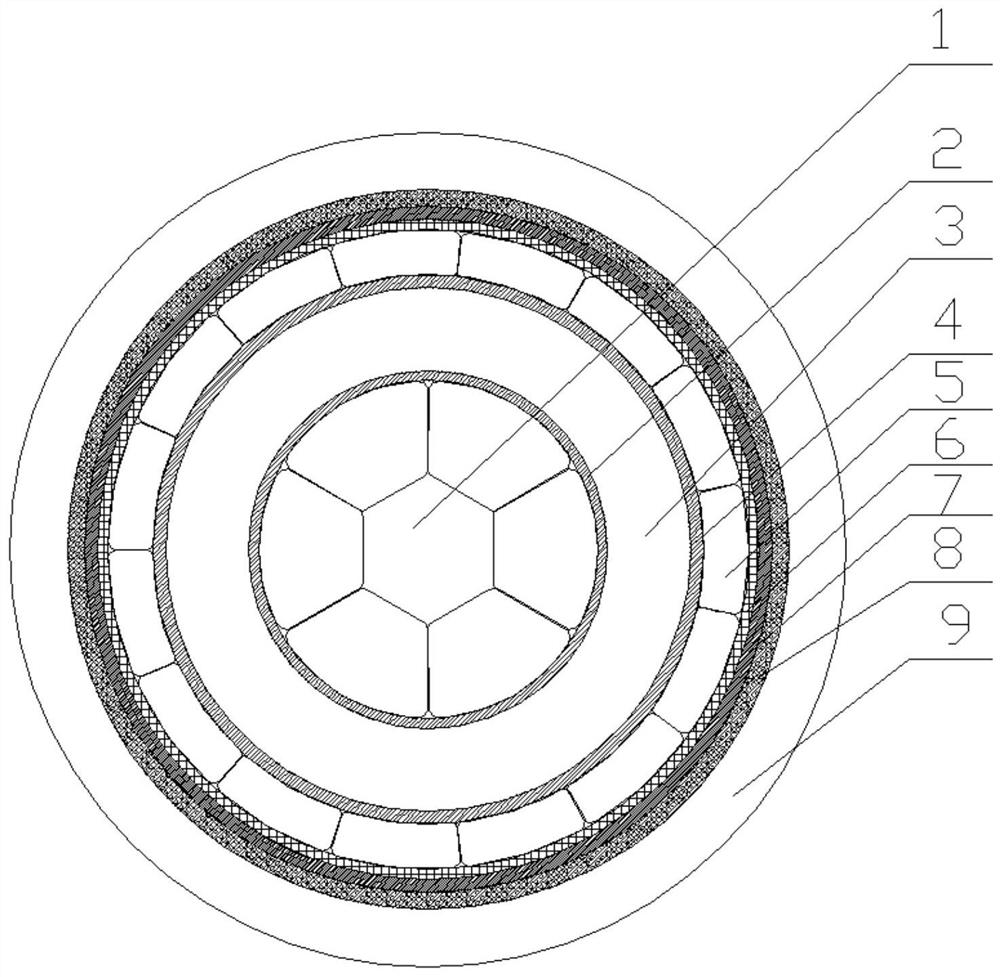

[0069] Such as Figure 1-2 As shown, a LNG ultra-low temperature DC-type medium-voltage coaxial cable includes an inner conductor 1, a shield 2, an insulating layer 3, an insulating shield 4, an outer conductor 5, and a copper tape wrapping 6 arranged coaxially from the inside to the outside. , tape 7, glass fiber protective layer 8 and outer sheath 9, the outer diameter of the insulated wire core composed of inner conductor 1, shielding 2 and insulating layer 3 is not greater than 11.1mm, the outer conductor 5 and inner conductor 1 are interconnected internally and externally, While playing the shielding role of the inner conductor 1 and equalizing the electric field strength of the inner conductor 1, the copper tape is wrapped with 6 gaps; the LNG ultra-low temperature DC type line medium voltage coaxial cable is not easy to break down, crack, and Thermal overload, stable electrical performance, long service life.

[0070] The inner conductor 1 adopts a 1+6 compact twisted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com