Immobilization method of microbial agent

A technology of microbial agent and microbial liquid, which is applied in the direction of fixing on/in the organic carrier, which can solve the problems of poor mass transfer, secondary pollution, and toxic microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

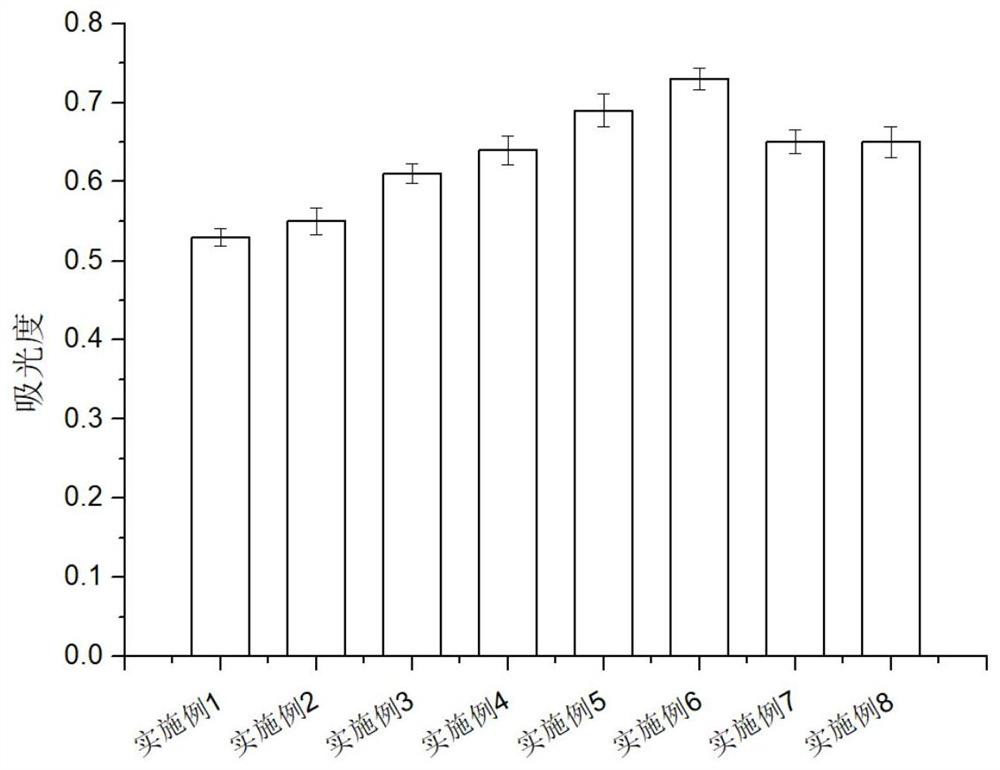

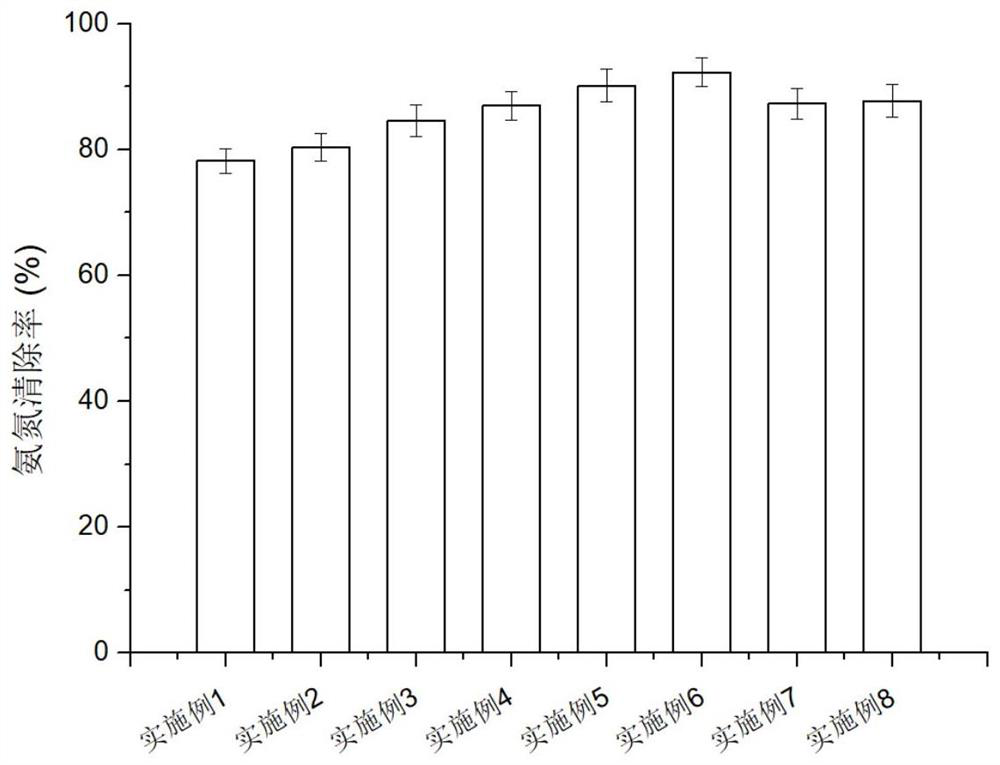

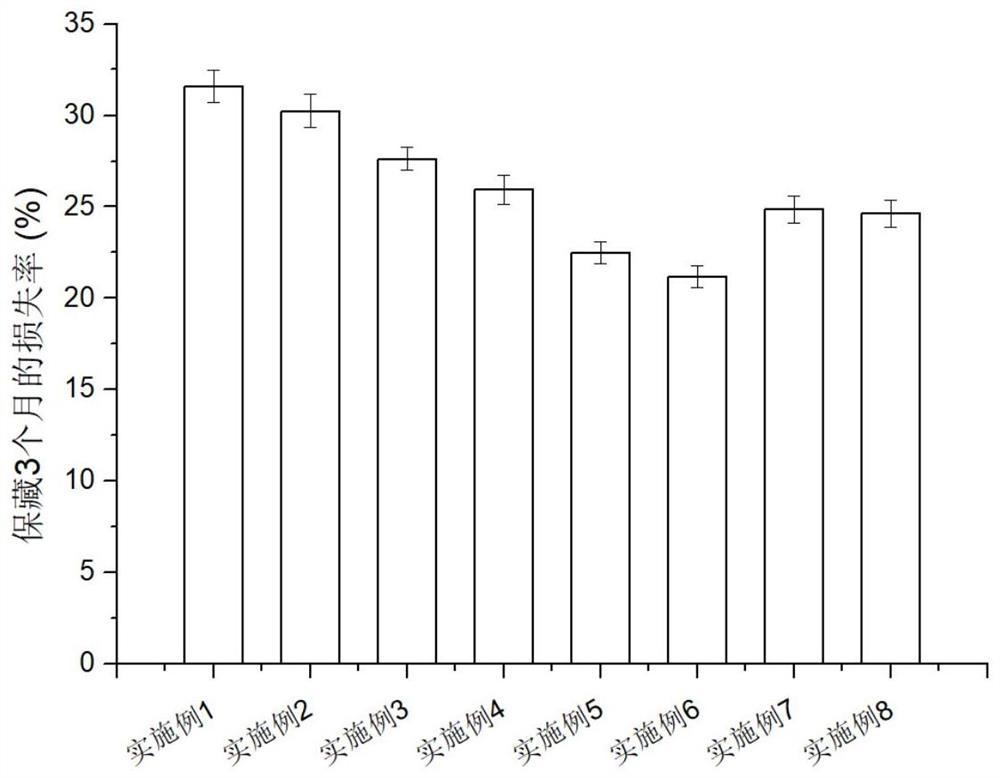

Embodiment 1

[0034] A method for immobilizing microbial bacterial agents,

[0035] Modification process: add the biological carrier into the hydrogen peroxide solution and oxidize it at a temperature of 25°C for 30 minutes, take it out and add it to an alkaline solution and modify it at a temperature of 25°C for 30 minutes, take it out, wash it and dry it to obtain a modified biological carrier; biological The carrier is corn stalk particles with a particle size of 100 mesh; the concentration of the hydrogen peroxide solution is 3wt%, and the amount of the biological carrier is 10wt% of the hydrogen peroxide solution; the alkaline solution is a sodium hydroxide solution containing sodium phosphate, and the hydrogen peroxide The mass fraction of sodium is 3wt%, the mass fraction of sodium phosphate is 0.5wt%, and the added amount of the biological carrier after oxidation treatment is 10wt% of the sodium hydroxide solution.

[0036] Immobilization process: mix the microbial bacterial liquid ...

Embodiment 2

[0038] Compared with Example 1, this example differs only in that the modified biological carrier is dipped and modified for 3 hours with an immersion solution containing xylo-oligosaccharides; the content of xylo-oligosaccharides in the immersion solution is 6 wt%.

Embodiment 3

[0040] Compared with Example 1, this example differs only in that before the immobilization process, the modified biological carrier is subjected to an immersion modification treatment with an immersion solution containing 2-bornylidene butanol for 3 hours; The content of xylan is 6 wt%, and the content of 2-bornylidene butanol is 1.2 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com